Utilizando el algoritmo del extremo de la sonda con el Levelflex M, de la empresa Endress+Hauser

Medición de nivel por microondas guiadas

Oliver Reher. Product Manager de Nivel de Endress y Hauser01/04/2006

El transmisor de nivel por microondas guiadas (TDR) Levelflex M de Endress+Hauser es capaz de medir el nivel en un silo o reactor bajo las condiciones de proceso más difíciles. Con el algoritmo del extremo de la sonda (patentado por E+H), este transmisor de nivel de última generación puede determinar qué nivel hay en el interior del depósito aunque no exista ninguna reflexión que provenga de la superficie del producto de proceso. Esta característica garantiza una medida de nivel fiable en las condiciones de proceso más desfavorables.

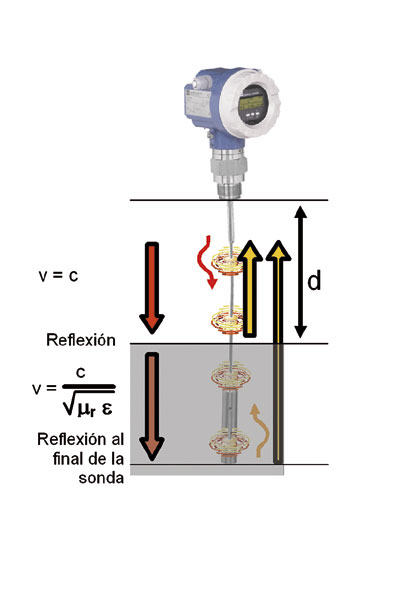

El Levelflex M es un transmisor de nivel basado en el tiempo de retorno de los pulsos de microondas que miden la distancia desde el sensor instalado en la parte superior del depósito hasta la superficie del producto en el interior del mismo. Un pulso electromagnético es lanzado y guiado a través de una varilla o cable metálico que actúa como línea de transmisión de la onda.

Cuando esta onda percibe una discontinuidad en el medio de transporte, por ejemplo un cambio súbito de constante dieléctrica entre el medio de transporte “aire” y el “producto” de proceso, parte de esta señal es reflejada y analizada por el transmisor de nivel. La distancia (nivel) se calcula dividiendo entre dos el tiempo medido entre la emisión del pulso y el retorno del pulso reflejado y multiplicándolo por la velocidad de la luz.

Parte de la energía que no ha sido reflejada por el producto de proceso reflejará en el extremo de la sonda de nivel.

Retraso en la propagación de la señal

Cada producto tiene un dieléctrico. El dieléctrico en el vacío es “uno” y cualquier otro producto estará referido a este vacío. Las ondas electromagnéticas se desplazan a una velocidad conocida en el vacío. Cuando estas ondas se desplazan en otro medio la velocidad cambia, de hecho, cualquier producto que tenga un dieléctrico mayor de “uno” reducirá la velocidad de desplazamiento de la onda. Un hidrocarburo (por ejemplo, diesel o gas licuado) se considera que tiene un bajo dieléctrico, en torno a 2. Este valor todavía es un 100 por cien superior al del vacío.

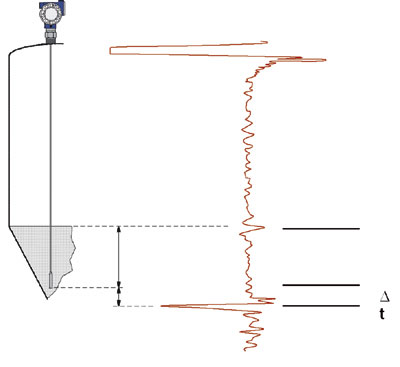

Deriva de la reflexión del extremo de la sonda

Cada transmisor de nivel tiene una longitud de cable o varilla conocida. El extremo de la varilla o del cable da una reflexión del final del guía ondas (además de la reflexión que se recibe de la superficie del producto). Dependiendo de la energía que se refleje en la superficie del producto de proceso, la onda electromagnética continuará su desplazamiento a través del cable o varilla guía ondas y habrá una reflexión de energía (en mayor o menor medida) en el extremo de la sonda. Sin embargo, la reflexión recibida desde el extremo de la sonda tendrá una deriva en el tiempo, ya que la onda electromagnética se está desplazando a través del producto de proceso. Esta “deriva en el tiempo” entre la reflexión del extremo de la sonda al aire y a través del producto, dependerá directamente de la cantidad de producto que haya por encima del extremo de la sonda.

El algoritmo del “extremo de la sonda”

El algoritmo de cálculo en el Levelflex M está ajustado de tal forma que la propia electrónica calcula el dieléctrico del producto utilizando la deriva en el tiempo que tiene la señal del extremo de la sonda cuando está cubierta de producto. Cuando la reflexión de la onda electromagnética en la superficie del producto se pierde, la electrónica lo detecta y pasa automáticamente a utilizar el algoritmo del extremo de la sonda hasta que vuelva a producirse una reflexión en la superficie del producto. Este tratamiento de las reflexiones garantiza una medida de nivel fiable en cualquier condición de proceso.

Influencia del dieléctrico del producto

El dieléctrico de cada producto es siempre diferente, y además cambia con la temperatura, humedad y a veces con la presión. En la práctica, cada producto incluso con el mismo nombre tiene un dieléctrico diferente. Este es el motivo por el cuál las sondas capacitivas son menos precisas que el Levelflex M, ya que no compensan los cambios que tenga el dieléctrico del producto. La velocidad de propagación de las ondas electromagnéticas se reducirá en gran medida cuanto mayor sea el dieléctrico del producto. Lo más importante es que el Levelflex M, calculará el valor que tiene el dieléctrico del producto (utilizando el algoritmo del extremo de la sonda) y medirá el nivel de producto que haya en el silo o depósito con precisión. El Levelflex M refresca cada 0,5 segundos la medida de nivel y la constante dieléctrica que tiene el producto de proceso.

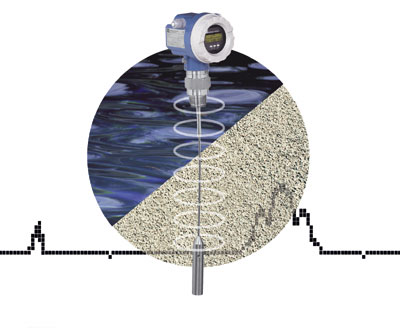

Utilidad en sólidos

Como se ha explicado anteriormente, el Levelflex M determina el nivel que hay en un silo o tanque de dos maneras. Primero utilizando la reflexión de las ondas electromagnéticas en la superficie del producto y segundo utilizando la señal del extremo de la sonda. Durante un llenado neumático o en una fluidificación, el gran ambiente pulverulento que se crea en el interior del silo genera mucho “ruido” en la medida de nivel. La señal reflejada de la onda electromagnética en estas circunstancias con un producto de bajo dieléctrico y con mucho ruido de fondo será muy baja. Aún así, como el Levelflex M utiliza los dos métodos de medida de nivel descritos anteriormente, siempre dará un medición segura y precisa del nivel bajo cualquier condición de proceso.

Utilidad en líquidos

Lo mismo pasa en aplicaciones con líquidos con bajo dieléctrico (hidrocarburos o disolventes) que sometidos a agitación, presión y temperatura puede facilitar que la reflexión de la onda en la superficie del producto desaparezca. En ese momento el algoritmo del extremo de la sonda le dará la posibilidad de continuar midiendo el nivel con fiabilidad.

Empresas o entidades relacionadas