Nuevas instalaciones piloto de extracción con fluidos supercríticos

Descripción del proceso

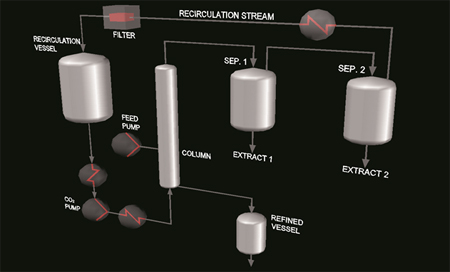

El CO2 en condiciones supercríticas (por encima de 31°C y de 74 bar) presenta una elevada densidad, solubilidad y altos coeficientes de transferencia de materia. Además, en esas condiciones su viscosidad es muy baja. Esto hace que su capacidad solvente sea muy elevada.

Cuando la corriente de CO2 en esas condiciones atraviesa un lecho de producto, el componente de interés es extraído de una manera sencilla y, en la mayoría de los casos, sin la utilización de disolventes cuya posterior eliminación es difícil y costosa.

Posteriormente se produce una despresurización de manera que el CO2 pasa de estado supercrítico a estado gaseoso con lo que pierde su poder solvente y en esa expansión ‘suelta’ el producto extraído en la etapa anterior. Puede ser necesario, dependiendo del proceso, una o varías etapas de fraccionamiento a diferentes presiones.

Finalmente el CO2 es recirculado mediante un proceso en el que interviene uno o varios filtros para eliminar parte del producto que pudiese haber arrastrado el dióxido de carbono y una condensación para almacenar el mismo en estado líquido y para que pueda ser bombeado de nuevo a la planta a la presión en la que la extracción tiene lugar.

A continuación se presenta un esquema típico de este tipo de instalaciones:

En la mayor parte de los casos las extracciones se producen entre 200-350 bar de presión y a temperaturas inferiores a 80°C. Esta tecnología es, por tanto, muy adecuada para productos termo sensibles.

Normalmente es necesario elaborar un protocolo de pruebas junto con el cliente, para determinar qué condiciones (presión, temperatura, relación disolvente/producto, etc…) son las más adecuadas para un proceso determinado.

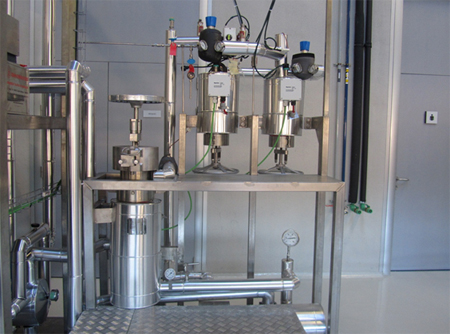

Diseño de la instalación

Las particularidades de diseño de este tipo de plantas están principalmente relacionadas con:

- Elevadas presiones de operación.

- Propiedades específicas del dióxido de carbono.

Elevadas presiones de operación

Las elevadas presiones de trabajo se traducen en unos espesores de equipos elevados. Este es uno de los principales motivos de la elevada inversión inicial que suponen estas plantas. Muchas veces es necesaria la optimización del material y su disponibilidad en el mercado para poder evaluar la opción más económica.

Por otro lado, los cierres usados, principalmente en las plantas de sólidos que trabajan en modo batch o semi-continuo, son de diseño complejo ya que deben ser seguros además de garantizar el cierre en las condiciones de operación. También deben ser fáciles de manejar por operarios en caso de instalaciones de pequeño tamaño o a través de polipastos para tamaños industriales.

Otro punto muy importante a tener en cuenta en el diseño de estas plantas son todos los sistemas seguridad asociados a estas altas presiones de operación, es decir, válvulas de seguridad, discos de ruptura, secuencias informatizadas de arranque y parada y un conjunto de enclavamientos y alarmas destinados a realizar siempre las operaciones de una forma segura.

Las propiedades específicas del CO2 hacen que haya que tener especial cuidado a la hora del diseño.

Exotermia: En las despresurizaciones se produce una exotermia que debe ser neutralizada mediante el correspondiente aporte de calor, ya que sino se produce la formación de nieve carbónica que puede obturar las tuberías e incluso dañar los internos de las válvulas de control debido a las solidificaciones en el interior de la mismas.

Abrasión: La diferencia tan elevada de presiones entre unos puntos y otros de la planta hace que el dióxido de carbono pueda ir a gran velocidad entre dos puntos causando problemas de abrasión, tanto en los internos de válvulas (manuales y de control) como en las juntas. El Vitón es uno de los elastómeros que nunca debe ser utilizado en estas aplicaciones.

Aplicaciones

Industria alimentaria: Son múltiples las aplicaciones dentro de la industria alimentaria debido a las bajas temperaturas de trabajo y para evitar la extracción clásica con disolventes: desalcolización del vino, eliminación de la teína del té, eliminación de la cafeína del café, obtención de extractos vegetales (tomillo, romero, pimentón), fraccionamiento de aceites, etc…

Industria farmacéutica: Purificación de principios activos, extracción de ingredientes de origen natural, etc…

Industria cosmética: Obtención de ingredientes de origen natural, eliminación de aromas, etc…

- Temperaturas moderadas de extracción (60-80 °C)→Adecuado para productos termo sensibles.

- Obtención de extractos y refinados sin traza de disolventes.

- No emisión de compuestos orgánicos volátiles a la atmósfera.

- Instalaciones NO ATEX.

- Al no haber presencia de oxígeno se evitan reacciones de oxidación.

- Posibilidad de variar calidades de extracto y refinado variando condiciones de operación de forma sencilla.