Almería welcomes the first floor which clears water with solar energy

So far these containers were burned, were abandoned or were buried, with the risk that the remains of pesticides might penetrate the soil and reach groundwater due to their high chemical stability, resistance to biodegradation and its high solubility in water.

A solution to this problem arises at the prospect of recycled plastic in these containers to other uses. But it is the problem that, following a selective collection, the containers must be washed before processing the material for re-use, resulting in a water contaminated with a mixture of different pesticides which should be treated.

As a result of this he thought in a simple and affordable technology for the treatment "in situ" of this water. Before this problem is presented as a promising application process of solar photocatalysis for degradation of pollutants, also referred to as solar detoxification, taking advantage of the energy provided by the ultraviolet radiation from the solar spectrum.

This technique provides an appropriate solution in an area of high insolation is the province of Almería. To demonstrate the feasibility of the process, was addressed in the platform Solar of Almería (PSA), in collaboration with various companies and public organizations, a study in this regard allowing a first sizing of a possible treatment plant. In 1994 was operating a pilot plant for carrying out the process.

This technology was developed by the Ciemat, together with a consortium of companies, which makes possible the practical implementation of the process of use of the solar light for the destruction of pollutants fotocatalítica organic persistent dissolved in water.

Evidence of this problem led Albaida natural resources and environment, S.A., to the processing of a project LIFE-Environment No.: LIFE00 ENV/E/000483, called: "Collection and environmental recycling of plastic containers of pesticides through solar photocatalysis"presented to the European Commission on 30/05/2001. Being the decision of the Commission on 14/08/2001, the granting of financial assistance pursuant to article 4 of Regulation (EC) No 1655 / 2000 of the Council (LIFE-Environment) for such project.

The process technology

The washing water, contaminated with residues of organic compounds that may be in packaging, passes to a storage tank. Before entering the field of solar collectors, water from washing suffers a physical-chemical treatment. The solids that might contain are removed by a filter or sieve. Later, in the conditioning tank is you added oxidants and the catalyst (FeSO4, 7 H2O, H2or2 and H2SO4) needed to carry out the reaction fotocatalítica.

In the tank is measured the concentration of TOC (Total organic carbon). If not achieved approximately 100 mg/l not begins the process of photocatalysis or solar detoxification, which is completed when at the exit of the collectors are 10 mg/l of COT.

Sunlight is concentrated on a glass tube that is transparent to ultraviolet light, through which circulates the water to treat. The modules are mounted on a fixed platform that allows his inclination to 37th. The modules are connected in series and the water flows directly from one to another and finally to a tank. A centrifugal pump is returning water to the collectors.

This system of solar detoxification based on the simple and efficient solar concentration with compound parabolic solar collectors, seems the best technological solution that also capture diffuse radiation. UV radiation is not absorbed by atmospheric water vapor and when there are clouds part reaches the Earth as diffuse light. This implies that the system runs on cloudy days.

The most remarkable aspects of this process are that it allows a complete oxidation of contaminants at room temperature, the necessary oxygen for the reaction is obtained from the atmosphere, and finally, energy can be obtained from an inexhaustible source such as the Sun.

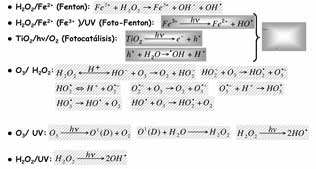

In this process fotocatalítico is going to use the photo-fentonsystem, in which ions faith2 + are oxidized with H2or2 producing a hydroxyl radical. The Fe3 + retrieved or their complexes absorb radiation producing radical free while the Fe2 + is regenerated.

The reagent of Fenton (described by H. j. H. Fenton at the end of the 19th century) consists of an aqueous solution of ferrous ions and hydrogen peroxide which provides an important source of hydroxyl radicals. Under acidic conditions (pH 2-4), this reagent is a powerful oxidizer of organic compounds. On the other hand, degradation of organic compounds speeds significantly increase to complement the process with UV/visible radiation, then calling process or Photo-Fenton method. In this case, the process becomes catalytic already the Fe ion2 + oxidized to Fe3 + in the Fenton reaction is reduced again to Fe3 + by action of the radiation, which already has a fotocatalítico process. Both reactions generate hydroxyl radical.

The use of Fe2 +/Fe3 + with other catalysts, such as titanium oxide, has the advantage that it is more its sensitivity to light, that grows to a length of 600 nm wavelength, which could make more use of solar energy that with other catalysts. In addition, having a homogeneous solution, the catalyst is dissolved in water, the penetration of light is higher and is controlled by the correct setting of the concentration of iron. Another advantage is that contact with contaminants is total. As disadvantage is the low required pH (< 3) to prevent the precipitation of hydroxides of iron and the need to separate the iron after the reaction.

The water can be recycled unless it reaches a conductivity of 10 dS/m. Once reached this value is its storage. The characteristics presented this water making it suitable for irrigation of crops in the region after mixing with water with a lower salinity.

The company

The main objectives posed Albaida, natural resources and environment are:

- Integrated water management: modernization of irrigation, sanitation, purification and reuse of waste water, supply rural villages, groundwater, municipal services for water management and remote management systems.

- Waste management: solid waste, agricultural and urban, logistics of collection, clean points and transfer and treatment and recycling plants plants.

- Management of the natural environment: scenic recovery, management and public use of natural spaces.

- Rural development: agricultural infrastructure, farm and rural equipment.

- Renewable energy production: gasification of plant waste from greenhouses and solar photovoltaics.

The future prospects of Albaida, natural resources and environment pass through the consolidation and expansion of its activity in peninsular Southeast, as well as the study and innovation of new technologies relating to the objectives in this article.

Bibliography

- J. White Gálvez; S. Malato Rodríguez. Solar photocatalysis technology. Use of solar radiation for the treatment of industrial pollutants. Monographic papers. 31. Institute for Almerian studies of the provincial Council of Almería; CIEMAT. 1996.

- J. White Gálvez; S. Malato Rodríguez; P. Fernández Ibáñez; J. Cácerez Vázquez; A. Campos Rodriguez; A. Carrión Muñox. Optimization of mineralization fotocatalítica of pesticides in a solar plant by addition of inorganic oxidizing species: application to the recycling of packaging of pesticides. Ciemat technical reports. February 2000.

- Treatment of waste water, waste and rubble in rural areas. Technical series. Tragsatec; School officer of agronomists of Centre and the Canary Islands. Agricultural Publisher Española, S.A. 1993.

- Agricultural in the poniente almeriense residues. Mediterranean environmental group. Almería G.E.M. 1999.