Biomass forestry in heating systems

January 23, 2009

Primary forest biomass (BFP) is considered possible energy bound material from work improving forest, clearing of stands, opening of stripes firewalls, priority protection perimeters, low mount and commercial use. They are primarily characterized by the heterogeneity of the material, scattered on the ground, and the high humidity of the Green material (with the possibility of reducing the content using the storage pool).

The main advantage of biomass is its dual role of savings in CO2 emissions. On the one hand, fossils, which have become the main cause of the emission to the atmosphere of CO2 and greenhouse is used as a substitute for the fuel. On the other hand, a bio-energy empowerment helps the reforestation of the planet, thereby increasing the amount of CO2 fixed.

The BPF is a practically zero, usually less than 0.1% sulphur. For this reason, the emissions of sulphur dioxide, which together with nitrogen oxides are responsible for acid rain, are minimal in the processes of energy transformation of this material.

In addition, this Woody material has a favourable balance of approximately 1 unit of energy invested for the obtaining of 30, and a growing degree of efficiency in the utilization and transformation of energy.

In terms of price, this and other woody biomass, fossil fuels are competitive context. In this way, the high initial investment of such facilities - its main disadvantage - can be amortized over several years thanks to the purchase of fuel savings.

The BFP as bio-energy use contributes to the creation of jobs in rural areas, to benefit the economic development of the area, as it's homegrown energy.

The installation

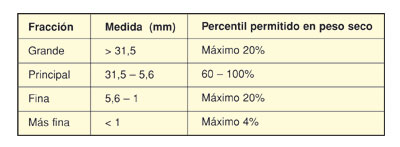

The most important properties to consider when buying the product are the particle size, moisture, species or group of species of origin, presence or not of leaves and bark, contamination by impurities or sand and percentage of ashes. As a general rule, to enhance the performance, efficiency and economy of boiler is desirable a consistent measure of the splinter, a low content of humidity and leaf litter, and a low production of ashes.

There are a variety of solid biofuels that can be used in systems of air conditioning of buildings. Examples include chips, the pellets, the bones of olives, nuts (almonds and pine nuts, among others) shells and the remains of pruning.

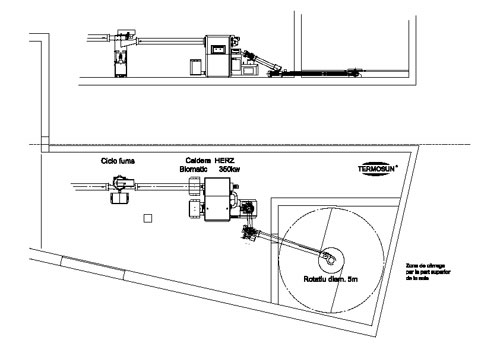

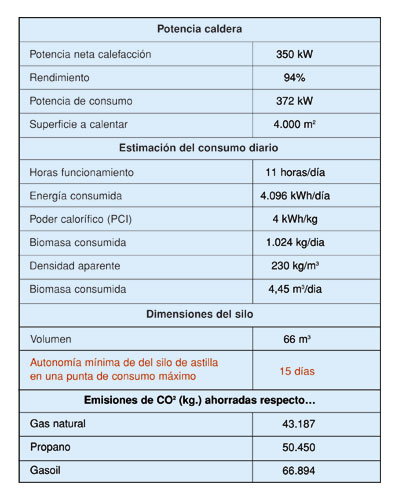

There is also a wide range of boilers and systems for the energy production of various European countries, high reliability and performance in the market. In the case of the CTFC is a caldera BioMatic BioControl 350, which works with powers of 79 to 350 kW, and whose operational details are explained below.

The caldera of the CTFC are used chips of BFP's measure G50, with a maximum of 35 per cent of content in water (W35), according to the standard MONTANINDUSTRIE M7133 (Austria and Germany).

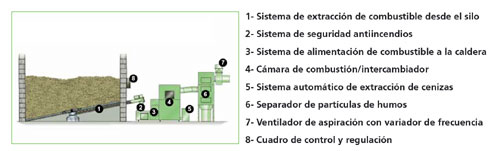

Parts of the installation

The main parts of a system of heating with biomass are the silo for storage of fuel, the feed system, the boiler, the deposit of inertia or accumulator of heat, the heat exchange system, the system for the disposal of ashesfume cleaning system and the installation of heating and/or hot water (DHW).

The silo of biomass has to ensure certain degree of autonomy of the installation. You are dimensions based on the consumption of the boiler, for a frequency of supply of once every one or two weeks approximately during the maximum consumption. It is also important that the unloading of the truck of supply can be performed by tilting, gravity though there are pneumatic systems.

The feed system moves biomass from the silo to the boiler by endless screws. The humidity of the fuel level is crucial to the ability of the caldera and the conditions of operation of the installation.

Lambda control placed in the output of smoke allows optimizing combustion and detect variations in fuel, regulate the higher secondary air and the amount of material fed. In this way, you don't need to reconfigure the parameters of the combustion when the silo is filled.

An interesting feature is the automatic cleaning of the heat exchange area during the operation. The surface of the tubes of Exchange will covering little by little particles, generating a loss of efficiency in energy uptake of Exchange. To maintain the maximum efficiency is necessary this part of the installation manual or automatic cleaning.

The CTFC, with forest biomass heating system

The system of heating of the new building of the Centre Tecnològic Forestal of Catalunya (CTFC) works with forest biomass of local origin. This provides a near-total autonomy from fossil fuels, significant economic savings and energy efficiency in heating.