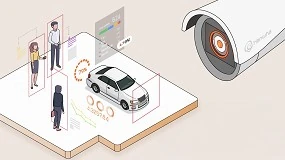

Intelligent cameras 3D of Sick in the setting in Ford Germany

23 April 2013

In Ford Germany, the Borrmann Company has instrumented a line of setting of bumpers, cover of maletero and capós with eight intelligent cameras IVC-3D of

The intelligent cameras 3D measure the position of the components in relation with the bodywork in the rough. Basing in the position of the tip in relation with the location of the lateral surfaces, the software calculates the position with a precision of a tenth of millimetre, transmitting the positions of atornillado exact to the robots by means of an interface RS-422.

In the workshop of setting of capós is not possible to use an aim of reference atornillado, by what the surface of the bodywork and the position of the orifices of main reference serves like norm of reference. To this end, two intelligent cameras 3D measure first the complete outline of the bodywork in the rough and afterwards determine the exact position of the orifices of main reference. During the measurement, the cameras displace on a sliding linear and, from the data of the encóder of this last, is possible to assign to each measurement a clearly determined position of the cameras on the bodywork in the rough.

To determine with precision the position of the bodywork, the software evaluates the position of the orifices of main reference and synchronises the results of the measurements of both scanners. This process provides all the coordinates and angles required for atornillar the components perfectly using tools of automatic setting for the screws and the nuts.

Both applications of measurement were developed by the signature of engineering Borrmann employing IVC-Studio. The processing of the images effects in IVC-Studio, evaluating each one of the four cameras in a system based in PC.