The technological centre turns into the ally of the companies so that they adapt to the factory of the future

Tecnalia launches to the market the technologies of the future of the manufacture

In 2011, the machines-tool invoiceed more than 770 million euros, 22% more than the previous year, what shows that it is a sector in peak, but also in full change. The factory that comes demands to the companies a replanteamiento in his procedures.

Thanks to his experience in the sector, Tecnalia has identified the exigencias of the factory of the future and has given them a solution by means of the investigation and the technology, and chose the last edition of the BIEMH to give to know these new tools. Each one of them answers to the new needs that will have the manufacture in the future to be sustainable and competitive: the flexibility in the manufacture, the optimisation of processes, the machines portables, the robotics of cables and the robotic colaborativa. These technologies answer directly to the key factors that progressively will incorporate the market of the manufacture in the short, half and long term.

David Sánchez, director of development of the centre, and Pedro Carnicer, director of the industrial division and of transport of the same, went the attendants of the presentations, incidiendo in the need of the companies of “innovar, externalizar and, in definite, replantear his protocols of performance”. In this sense, the R&D plays a fundamental paper to develop new solutions, equipment and projects that allow to improve the processes of production. And here it is where goes in at stake the work done in centres like Tecnalia.

Flexible manufacture

David Sánchez aimed that “in the future we will speak of processes more flexible, sustainable and, at the same time, more intelligent”. To do this possible, Tecnalia bets for entering in the processes machines that are able to adapt to the circumstances of the surroundings and act in consequence, as when a machine that displaces by the plant of elusive manufacture obstacles of autonomous way.

An example of this is the robot of welding that Tecnalia exposed in the Biennial, able to work on different pieces without need to move them, since it is the robot the one who displaces to each one of them, saving the time and the costs to move each one of the pieces and taking advantage of to 100% the performance of the machine. The strategic collaboration that from does years Tecnalia has with Fanuc has been key in the development.

Optimisation of processes

To guarantee the optimisation of the processes, Tecnalia proposes machines ecoeficientes that guarantee and increase the quality of the products, reducing the consumptions and costs of operation. In this sense, the centre showed a tool holders intelligent that reduces the necessary strengths to realise a cut on a material, what improves the quality of the result and lengthens the life of the tool. “This supposes a saving of power, a step more in the bet by sustainability in the systems of production”.

Portable machine

The flexible and intelligent automation of processes at present complex and expensive to automate is another of the tendencies that predominates in the factory of the future. Tecnalia leads the design of machines that displace of autonomous form on the own piece on which is working, as for example, a robot ‘garrapata' that cuts the sheet of the external case of fuselages out of use to facilitate the works of recycling. This machine is a form to carry the factory to the ship to simplify the cycle of life of the product and to arrive to zones before impossible and unsure for the people.

treats of a machine to cut sheet in fuselages out of use. It incorporates some electroimanes with which sustena the sheets and transports them to the place of download wished.

Between the advantages of this technology stands out that it supposes a lower initial investment, with a fast return of this. Besides, it allows a greater reusabilidad of the means of produción, as well as a greater efficiency and simplification of the flow of production, beside a greater flexibility in front of changes of production. Likewise, it is a fast system and fácl to install, with light structure and ecoeficiente.

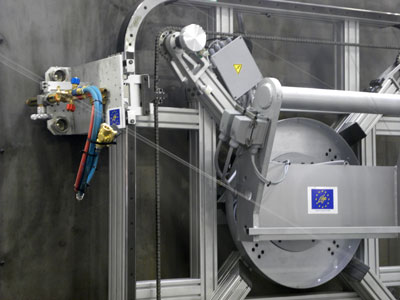

Robotics of cables

The robotics of cables is cream by the need to work on loads that it is necessary to move with precision and in wide spaces, like sucede in the nautics or aeronautical sector component manufacturing sector component manufacturing sector, for for example paint the surface of a ship and protect to the operarios so much of the toxicity of the product as of the risk to realise these operations hanged of the structures or gone up in platforms to a lot of height. The prototype developed by Tecnalia, with a similar operation to the movement that realises a spider when gliding by the cloth, guarantees the hygiene of the workers and the precision in the movements.

Robotic colaborativa

99% of the tasks are more efficient combining the intelligence of the human being with the properties of the industrial robots. Thus, Tecnalia bets by the robotic colaborativa through robots like Hiro or the arm Ligth Weight, that can work with the people in absolute conditions of hygiene. Hiro Is the first robot humanoide that will work elbow with elbow with the people in the European industry, what will improve the quality of the processes and will allow to increase the competitiveness of these companies in the international markets.

By his part, Ligth Weight is the best student of the human being, since it is able to repeat a movement after a worker have taught it to him an only time, what facilitates the programming of the robot for the realisation of the automatic operations.

- Hiro bi-arm of Kawada, an only model out of Japan. Used for the automation of operations of remachado in structural components of the aeronautical sector component manufacturing sector component manufacturing sector (rib), yielded by Airbus to show in the BIEMH 2012.

- Light Weight Of Kuka, prepared to work with people of safe way.

Between the advantages of this technology stand out the partial automation of manual operations too complex, the reduction of costs of complex toolings and the improvement of the utilisation of the space and infrastructures.