Optimización de procesos de envase y embalaje en máquinas y líneas automáticas

21 de julio de 2010

En una sociedad de vocación consumidora como la actual, el envase cobra una importancia sin igual. Los efectos en el consumidor de los diferentes envases y embalajes contenedores son de muy diversa naturaleza.

En una gran superficie un consumidor dedica, por término medio, 5 segundos a cada producto exhibido en los diferentes estantes, siendo éste el tiempo que tiene el envase, con su poder diferenciador, para convencer al potencial cliente de las bondades del producto (Cervera, 1998).

De acuerdo con la FAO (Organización de las Naciones Unidas para la Alimentación y la Agricultura) el uso de unos adecuados envases y embalajes permitiría reducir las pérdidas de alimentos, reduciendo el hambre en el mundo; estas pérdidas se pueden cifrar entre un 30% y un 50% (tercer mundo) y entre un 3% y un 5% (países desarrollados) (Packforst, 2000).

El número anual de palés y embalajes que pueden mover en los almacenes de una gran empresa de distribución supera los 130 millones de unidades; evidentemente, todo esfuerzo por hacer más eficiente, tanto la agrupación de envases en un embalaje como la agrupación de embalajes en un palé, redundará en una importante reducción de los costes de manipulación, almacenamiento y transporte (Henriksson, 1998).

En una economía desarrollada, una persona consume a lo largo de su existencia 130 veces su propio peso (70 kilos) en envases domésticos; a estos residuos habría que añadir su participación en el consumo de envases industriales o embalajes (Cervera, 1998).

Con todos estos datos sobre la mesa, es evidente la importancia de los procesos de envase y embalaje para los diferentes productores de alimentos y bienes de consumo. Su optimización, tanto a efectos de coste, productividad y eficiencia energética, es primordial y prioritaria para dichos productores.

Flexibilidad de adaptación a cambios rápidos de formato, mecatrónica

Tanto al diseñar una línea automática, como al estructurar un proceso de embalaje, el concepto de producción flexible debe ser una prioridad. Dos puntos han de tenerse en cuenta: la conectividad de los parámetros y órdenes necesarias por parte de la gestión de producción, y el ajuste automatizado de profiles de movimiento y posiciones de topes, alturas, formas o espesores. Centrémonos en este último apartado.

En una máquina o línea automática, nonios y ajustes manuales con manivelas pueden y deben reemplazarse por sistemas de posicionado. Sumado a esto, una eficiente gestión de recetas permitirá que las máquinas o líneas cambien de formato de envasado o embalaje con un esfuerzo y tiempo mínimo.

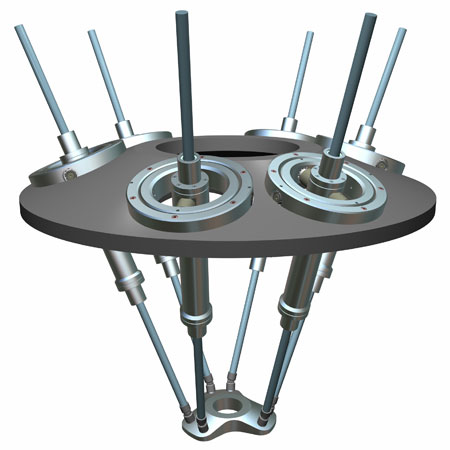

Para ello, la gama de actuadores eléctricos lineales de Larraioz ofrece la más sencilla solución para el posicionado de carros, topes o cualquier otro mecanismo que requiera bien un pre-posicionado o un movimiento durante el proceso en sí mismo. Básicamente dos familias cubren estas necesidades: Robocylinder y MPC (multi position Cylinder).

Los actuadores RoboCylinder son equipos destinados a la sustitución de los dispositivos neumáticos. Fabricados por la casa japonesa IAI, quien propone una enorme diversidad de modelos de actuadores electromecánicos (más de 3.000 referencias) de amplia utilización en el proceso de envase y embalaje de producto.

Estos elementos permiten de una forma sumamente sencilla controlar el movimiento de un tope, una altura, profundidad, etc… logrando de esta forma realizar todos los ajustes de una línea de forma automática, sin manivelas manuales, sin reglas, trasductores externos, ni ningún otro dispositivo de medición o lectura.

Cambios de formato, ajustes en ciclo o incluso movimientos de interpolación, son ahora tan fáciles de realizar como la instalación de un cilindro o una electroválvula.

Tanto el operario de mantenimiento sin especiales conocimientos de ejes o Motion, como el fabricante o instalador de máquinas y líneas de envasado y embalaje, pueden a partir de este momento, instalar, configurar y poner en marcha los sistemas de ajuste automático de línea con escaso esfuerzo por su parte. Sin ajuste de parámetros complejos, sin cableados de sensores externos, sin finales de carrera: los nuevos RoboCylinder permiten realizar movimientos con recorridos máximos hasta 3m, repetitividades de posicionado de 0,01 mm, velocidades de hasta 3 m/s y fuerzas ajustables de hasta 2 t..

Diferentes tipos de controladores de IAI permiten configurar fácilmente un sistema complejo de actuadores, desde simples órdenes de posicionado hasta complejas funciones de relaciones entre ejes como comando de robots cartesianos o Scara, o sincronismos con dispositivos externos como cámaras de visión para ejecución de tracking de producto. Todo ello gestionado mediante simples señales digitales o diversos buses de comunicación como Modbus, Profibus o DeviceNet, entre otros…

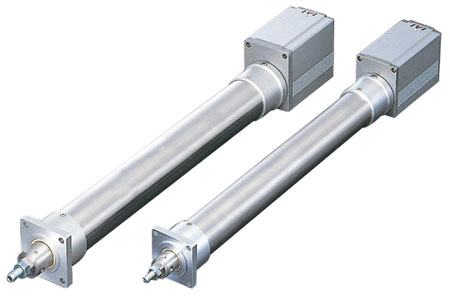

Los dispositivos MPC se basan en motores lineales de la prestigiosa firma suiza LinMot. Motores de vástago y estator independientes, que no llevan ningún tipo de transmisión entre sí. De funcionamiento silencioso, los motores lineales MPC, son accionamientos electromagnéticos lineales, libres de desgaste, sin reductores intermedios, husillos o correas.

El motor consta de sólo dos elementos: el vástago actuador y el estator. El vástago se compone de imanes de Neodimio montados dentro de un tubo de acero inoxidable de elevada precisión. El estator contiene los devanados, sensor de temperatura y una tarjeta electrónica integrada. Esta tarjeta controla la posición del estator por tecnología Sensor-Less lo que da una elevada repetitividad de hasta 0,05 mm sin necesidad de delicados transductores de posición.

El diseño del motor se basa en un efecto de levitación magnética ya que el campo se produce en los 360 grados del estator. Esto además provee al sistema de una capacidad extremadamente dinámica: velocidades superiores a 6 m/s y aceleraciones mayores de 300 m/s2 (30G) sin ningún tipo de transmisión mecánico. Los recorridos máximos alcanzan los 2000mm y pueden desarrollar fuerzas de 1.000 N.

Sus controladores facilitan además la sincronización de movimientos, lo que permite realizar de forma muy sencilla un pórtico en “gantry”, o un sistema de levas electrónicas, corte al vuelo, sincronización por mácula… etc.

Todos estos sistemas se proveen en conjunto, motor + regulador + cables, con distintos grados de protección hasta IP69K, que le hacen adecuado para el trabajo en ambientes de grandes requerimientos de estanqueidad e higiene como son las industrias alimentarias, farmacéuticas o químicas. Soluciones de acero inoxidable cumplen los más exigentes requisitos de los diferentes sectores.

Las prestaciones de LinMot no acaban en sus actuadores. Las familias de controladores B1100 y E1100 permiten funciones de control de movimiento tales como posicionados simples, programación de secuencias completas de movimiento, ejes Gantry, relaciones maestro-esclavo con otros ejes mediante levas libremente definibles, o streaming de posición, posición-velocidad o posición-velocidad-aceleración. Las diferentes configuraciones de interacción pasan por las alternativas de control mediante señales digitales, posibilidad de consignas analógicas para posición, velocidad o fuerza, o buses de comunicación como RSLink sobre RS232 o RS485, DeviceNet, CANOpen y ProfibusDP. La nueva familia de controladores E12xx incrementa las prestaciones de potencia de los motores lineales, reduce los tiempos de los lazos de control optimizando la gestión de los actuadores, e incorpora nuevos buses de Ethernet basados en tiempo real como son EtherCat, PowerLink, Ethernet/IP, Sercos III, ProfiNet.

Eficiencia productiva y energética, vida útil

El uso de la energía de una manera eficiente recortará de forma sustancial los costes de funcionamiento de la instalación y/o máquina, además de beneficiar el medio ambiente. Es evidente y esencial una convergencia plena entre las necesidades de desarrollo tanto empresariales, como de medio ambiente. La evolución de nuestra empresa y el desarrollo sostenible deben ir de la mano.

Es habitual el uso extensivo de sistemas neumáticos en las líneas y máquinas relacionadas con el proceso de envasado, embalaje y empaquetado, cientos de cilindros pueden formar parte de la secuencia de manipulación de producto y contenedor, sin que seriamente se planteen los costos de la utilización de esta energía.

Tanto los RoboCylinder como los MPC son dispositivos diseñados con el objetivo clave de sustituir los tradicionales sistemas neumáticos. Los actuadores lineales de IAI (Japón) y los motores lineales de LinMot (Suiza) utilizan la fuerza eléctrica como única fuente de energía de transmisión mecánica. Con estos dispositivos podemos realizar operaciones tan simples como las que realiza un cilindro neumático, desplazar una masa de un punto a otro, pero el hecho de que sean sistemas servocontrolados nos permitirá tener un control total de parámetros del movimiento tales como la aceleración, deceleración, velocidad, fuerza, … además de infinitas posiciones de destino, realmente complicado de conseguir con las soluciones neumáticas. También podremos realizar funciones mucho más complejas como sincronizaciones e interpolaciones entre diferentes ejes, emplear múltiples buses de comunicación y protocolos para enviar las secuencias de movimiento, obtener un feedback de la posición actual y estado de los actuadores...

Con los sistemas neumáticos, un compresor funciona mediante electricidad para generar el aire comprimido necesario para dichos actuadores. El aire generado es suministrado mediante una red de tuberías y otros circuitos de transmisión del aire a los cilindros y otros actuadores neumáticos. Es en estos últimos dispositivos donde esta energía se convierte en una fuerza de movimiento lineal. Este conjunto de mecanismos está sujeto a una pérdida energética sustancial.

Según el Instituto Tecnológico de Tokio, la eficiencia energética de los dispositivos neumáticos ronda el 14%. Del 100% de la energía consumida…

-Un 50% de la potencia se pierde en el propio compresor de aire, debido a diferentes factores como las propias pérdidas energéticas de compresión de aire, las pérdidas del motor del compresor, las pérdidas de los ciclos de marcha-paro…

-Un 16% de pérdida de energía en las diferentes válvulas de reducción y adaptación de presión.

-Un 5% de pérdida de energía en el tratamiento del aire, filtros…

-Un 15% de pérdida de energía en el propio actuador neumático.

Además, los sistemas de aire comprimido siempre tienen fugas.

Actualmente muchas instalaciones sufren unas pérdidas por fugas que representan entre el 25% y el 30% del consumo total del compresor. Un orificio de 1mm de diámetro en el circuito de aire supone una fuga de 3,5Nm3/h de aire, uno de 5mm 85Nm3/h y esto a los costes actuales de electricidad supone un desperdicio de 7300 euros anuales, sin tener en cuenta el deterioro medio ambiental que esto produce, el gasto en sí ya es más que considerable.

Con RoboCylinder, las revoluciones de giro del motor eléctrico rotativo se convierten mecánicamente en fuerza de movimiento lineal mediante un sistema de transmisión energéticamente eficiente.

Con MPC en cambio la propia energía eléctrica del motor se transforma en un trabajo lineal, ni siquiera hay un sistema mecánico de transmisión de fuerza circular-lineal. La eficiencia energética de ambas familias oscila entre el 80% y el 92%, lo que conlleva unos costes energéticos de funcionamiento de entre un tercio y una décima parte de lo que supondría la factura energética de los sistemas neumáticos.

El cilindro neumático obtiene la energía a través de la presión de un caudal de aire comprimido sobre un émbolo. Todas las fases del movimiento, aceleración, velocidad constante y deceleración consumen potencia producida por el compresor a partir de electricidad. La diferencia de energía entre la consumida y la producida en el movimiento se traduce directamente en pérdidas, ya que los sistemas neumáticos no pueden devolver energía al compresor. En cambio, en los actuadores de RoboCylinder o MPC se utiliza directamente la energía de la red eléctrica con un alto grado de eficiencia, consumiendo únicamente en las fases donde realmente hay trabajo, es decir, en las fases de aceleración, y además devolviendo al controlador la energía producida en las fases de deceleración.

La utilización de sistemas neumáticos conlleva, en líneas automáticas de envase y embalaje, a cantidad de errores debidos a fluctuaciones en la presión de aire, hecho que deriva en demoras, rechazos o problemas de calidad. La utilización de RoboCylinder y MPC reducen enormemente el porcentaje de rechazos o fallos, ayudando de esta forma a una mejor eficiencia y rendimiento del proceso. Al hablar de sistemas de posicionamiento multipunto y con repetitividades hasta 0,01 mm, o incluso superiores, se comprenderá que tanto los tiempos de los procesos de envasado y embalaje como los ciclos de cambio de formato se puedan llevar a niveles óptimos.

Un último parámetro a tener en cuenta es el de la vida útil de los diferentes dispositivos y su mantenimiento. La estimación de vida de un cilindro neumático de un recorrido menor a 100 mm es de 25 millones de ciclos, o 10.000 km para cilindros de carrera superior a los 100 mm. La vida útil de los actuadores MPC supera los 500 millones de ciclos. Una solución neumática ejecutando un ciclo por segundo no soportaría un año, frente a los 15-20 años de esperanza de funcionamiento del actuador MPC.

Todos los Robocylinders de IAI disponen como estándar de AQ seal, que consiste en una banda de resina impregnada de lubricante solidificado. Esta innovadora tecnología de lubricación asegura una no necesidad de mantenimiento durante 5.000 km de desplazamiento o 3 años.

Automatización de máquinas y líneas de envase y embalaje

La extensiva automatización del proceso de envase y embalaje, no es un imposible, es más, es un enorme valor añadido para quienes consiguen hacerlo a precios racionales. La diversidad de la producción de una determinada empresa, la diferente demanda de formatos de su envasado, y una adaptación rápida de un modelo a otro, requiere de una solución: automatización.

Automatización sí, pero racional, con un interfase gráfico fácilmente entendible por los operarios de las líneas automáticas, con una gestión apropiada de recetas y órdenes, y con una eficiente comunicación a la oficina de producción que gestiona las necesidades de envase y embalaje de la producción en tiempo real.

El interfaz de usuario, interfaz hombre-máquina, o más comúnmente conocido por sus iniciales en inglés HMI (Human-Machine Interface), es todo un conjunto de componentes, tanto de Hardware como de Software, que permiten al operario comunicarse e interactuar con el control de una máquina o línea de proceso.

Los principales requerimientos de los interfases industriales siempre han sido, y deben de seguir siéndolo, tanto la operatividad como la robustez y estabilidad de comportamiento. Las condiciones ambientales en las que se encuentran estos sistemas en las plantas de las industrias alimentarias o farmacéuticas entre otras, no son las ideales y nos podemos encontrar con situaciones no deseadas, pero inevitables, como temperaturas extremas, humedad… a las cuales debe de estar preparado el interfaz.

En base a la importancia de las comunicaciones, ya sea con el operario o con los distintos departamentos, en Larraioz hemos desarrollado sistemas HMI mixtos, pensados específicamente para enriquecer el “Diálogo” con el operario.

Estos sistemas de concepción modular integran una pantalla táctil de 7”, 10”, 15” o superiores, además de pulsantería luminosa de tipo capacitivo, todo en un mismo frontal sin rebajes ni salientes. Las opciones de pantalla de HMI abarcan los diferentes formatos 4:3 y 16:9, permitiendo la utilización eficiente de las herramientas multimedia tales como reproducción de videos, representación de PDFs, comunicación de MMS, … La retro iluminación de las pantallas se realiza mediante tecnología LED, lo que otorga un brillo superior, minimizando los problemas de falta de claridad (problema habitual en las pantallas tradicionales al envejecer la lámpara).

El uso de los pulsadores luminosos permite que el manejo más frecuente o prioritario del proceso-máquina, se haga mediante éstos, eliminando la necesidad de reiteradas pulsaciones en la pantalla y aumentando además la vida de la misma.

Cada pulsador incorpora una banda luminosa exterior en amarillo, verde, rojo o azul, que puede rotar a derecha o a izquierda, rápido o lento, ponerse intermitente rápido o lento, indicar direcciones, quedarse encendido, etc…Estas posibilidades de visualización, son enormemente informativas para el operario y reducen notablemente los riesgos de error de operación, al asociar estados luminosos a funciones o disfunciones de la máquina.

Los dispositivos HMI de Larraioz pueden incorporar, opcionalmente, lectores RFID, para una identificación rápida y segura del operario y partidas. Las formas y metodología a la hora de asignar imágenes y asociar símbolos a estados, hacen que una aplicación sea fácilmente entendible e intuitiva para el operario de línea o máquina. Sumado a esto, la posibilidad de visualizar videos de ayuda o asistencia en pantalla, otorgan al programador–integrador, las posibilidades de hacer un sistema amigable.

Entornos Scada como Genesis32, Genesis64 y BisViz permiten diseñar espectaculares aplicaciones gráficas y de gestión de producción con un óptimo tiempo de desarrollo. Herramientas como GraphWorX, TrendWorX, AlarmWorX, WebHMI o MMX, completamente modulares, dan lugar a aplicaciones gráficas tan diversas como las de una máquina simple, una línea completa de producción o un proceso global de envase, embalaje, almacenamiento y logística de una empresa o grupo de empresas.

Con la convergencia de procesadores de 64 bits, multi-núcleos y multi-procesadores, la introducción de los nuevos sistemas operativos Microsoft de 64 bits, y la demanda de aplicaciones nativas que aprovechen dichos recursos, Iconics introduce Genesis64, la nueva generación de visualización HMI/Scada. La Suite de Genesis64 incluye diferentes soluciones que permiten la conectividad de la planta de producción e instalaciones al sistema de negocio corporativo. Diseñado para exprimir las ventajas de conectividad OPC UA, código gestionado sobre.NET y tecnología SharePoint, permite a los operadores de planta y a los profesionales de IT integrar el concepto de “negocio y producción en tiempo real”.

El nuevo GraphWorX64 provee la plataforma para visualización, tomando la máxima ventaja sobre exquisitas representaciones en 2D y 3D en aplicaciones HMI y Scada. El usuario puede construir gráficos escalables basados en vectores XAML que no pierden detalle cuando se ejecuta un zoom. Asimismo Genesis64 toma también ventaja sobre la apariencia de transparencias de Aero, o integración de otras herramientas y aplicaciones como Microsoft Office. El colofón ideal supone el soporte de interacción multitáctil con la pantalla, lo que permite al operario relacionarse con la aplicación mediante comandos Gesture para navegar de forma total sobre ella, ampliar o reducir un área de visualización, rotar y cambiar vistas, desplazarse, …

Como complemento idóneo a la visualización de Scada para sistemas operativos MS Windows, Larraioz ofrece, como herramienta de conectividad, la comercialización y servicio técnico de Kepware.

Kepware, Estados Unidos, es líder mundial en software de comunicación para automatización, y ofrece una experiencia única en OPC y conectividad de dispositivos Embedded. Kepware se centra en el desarrollo de drivers de comunicación para controladores de automatización, puntos de entrada/salida y dispositivos periféricos de campo, para los sistemas operativos de MS Windows tales como Microsoft Windows Desktop (Windows XP y Windows 7), Server y Embedded (Windows CE, Windows XP Embedded o Windows Embedded Standard 7).

Kepware es miembro de la fundación OPC (OLE for Process Control), el más conocido y extendido estándar de comunicación industrial, permitiendo el intercambio de datos entre dispositivos de diferentes fabricantes y las aplicaciones de control, sin ningún tipo de restricción propietaria. Los servidores OPC permiten comunicar la información entre distintos PLC, dispositivos RT de campo, las estaciones de HMI y Scada, y las aplicaciones de software instaladas en los ordenadores de control de proceso. Aún y cuando los Hardware y Software provengan de diferentes fabricantes, el cumplimiento de OPC asegura la viabilidad de una comunicación continua y en tiempo real. Para dispositivos que no dispongan de soporte de conectividad OPC, el servidor de protocolo U-CON permite el rápido y sencillo desarrollo propio de drivers de comunicación para casi todo dispositivo con bus serie o Ethernet, tales como escáneres de códigos de barra, lectores de RF, células de carga, sensores, y toda una enorme gama de controladores industriales.

La herramienta KEPServerEX ofrece ahora el nuevo Servidor OPC UA, junto con la opción de driver Cliente OPC UA. Con soporte para más de 140 diferentes drivers y protocolos de comunicación, la conectividad OPC UA provee una solución robusta y segura de Tunneling para evitar las aplicaciones distribuidas sobre DCOM y habilitar el concepto de ‘B2B para automatización’.

Larraioz ofrece como añadido, productos embebidos de Genesis y Kepware en sus controladores MIPC, ya instalados, y de precios altamente competitivos, que cumplen los más amplios requisitos de conectividad y visualización requeridos por la mayoría de los sectores productivos y de envase y embalaje alimentario, químico y farmacéutico, …

Más de 20 años en automatización de máquinas y procesos

En la propuesta de Larraioz Electrónica Industrial se mezclan más de 20 años de duro trabajo al servicio de la industria, investigando constantemente nuevos productos y mercados, desarrollando soluciones para resolver de forma eficiente las más complejas labores de automatización.

Y cuando hablamos de soluciones incluimos todo el sentido de la palabra: producto de gran prestación y calidad, amplio conocimiento y soporte sobre el mismo, logística rápida y stock permanente, precios competitivos y, lo que es más importante, un enorme capital humano capaz de dar solución a las más complejas necesidades de automatización.