Carl Software goes in in the Belgian market in style

Disgust Industries has plants of production in Belgium, Germany, Canada and soon will manufacture in United States. Besides, has points of sale in France and Brazil and a department of engineering in Seattle (EE UU). In total, the group has a staff of more than 1.300 employees. The dimension of the company and the high requirements of the aeronautical sector component manufacturing sector component manufacturing sector, did necessary to adopt a system of maintenance and control of production of solvency contrasted.

Dominique Balme, responsible of communication of Carl, Eric of Wever, responsible of development for Flandes and Low Countries of Carl, and Paul-Henri of Fays, general director for the Benelux of the French signature, presented the position of the company in this zone beside the novelties promoted in the last months. They accompanied them Nathan Dewinter, engineer of systems of information of management of maintenance of Disgust, and Alain Catanese, boss of maintenance of the aeronautical sector component manufacturing sector component manufacturing company.

Carl Source 4, the natural evolution

Carl Source 4 stands out by his “new design and a totally reinvented ergonomics”. His modules and icons of design ‘user friendly' convert to Carl Source 4 in a more next software to the user, easy to use and intuitive, with the integration of the last technologies of Internet. Supporting in the experience of thousands of users of Carl Source from his launching in 2008, the new version contributes big quantity of improvements. Like this, his users find now graphic indicators customised in the screen of start, an arborescencia of equipment more complete and intuitive, massive update of data, integration of joins functionality ‘Memo' exclusive, in addition to numerous improvements by sector of activity: management of goods and surfaces integrating notions specify to the management of the heritage, management of accidents and import of consumptions of fuels for the version transport, new functionalities oriented to the service posventa and service companies, between others.

Two exclusive novelties in Carl Source 4

- Reports of the organisms of control: Carl Source 4 can matter the reports of the main organisms of statutory control. These reports download directly from the platforms of the organisms and integrate automatically in Carl Source. From these reports, the program generates the actions of necessary maintenance to fix the reservations formulated during the control. The trazabilidad and the follow-up of the reservations in his equipment or his buildings are like this guaranteeed, ensured and optimised.

- Carl Source 4 integrate Google Maps and flat Autocad: the program teachs his planes Autocad in the format.dwg In the same window that the arborescencia of his equipment. The planes no only visualise but interactúan with Carl Source: with a simple click in a part of the plane, can execute actions of maintenance directly in the team selected (creation of an application of intervention, of a report…) Carl Source 4 integrates of the same way all the able external applications to manage planes via web service: Systems of internal Geographic Information or external (like Google Maps) or other tools of management of planes.

And, again, Carl Source 4 works with different interficies, allowing his integration in diverse applications, what facilitates his implantation home of the customer.

A system of pioneering management for a leading company

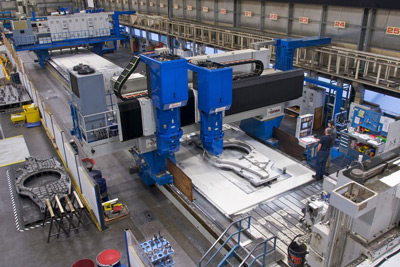

Disgust, a company 100% deprived in hands of the second generation of the family that gave him life, occupies of all the process of production of his products —except pieces no critical that subcontract—, by what was necessary to have a system of supervision and maintenance highly reliable and in the innovative line of the own company. Disgust works continuously in new technology to improve the aerodynamics of the aeroplanes to end to reduce the consumption of fuel and the global ecological footprint. This has turned them into one of the main partners for the design and manufacture of the systems of elevation and landing for some of the main commercial aeroplanes and military. Thus his system of quality and management of the production has been approved by some manufacturers like Airbus, Avcorp Industries, Boeing, Bombardier, UTC Aerospace Systems, Latécoère, Lockheed Martin, Messier-Bugatti-Dowty, Mitsubishi Heavy Industries, Premium Aerotec, among others. A management for which, from now, has the support of Carl. Like this it explained it Alain Catanese during his intervention “the aeronautical sector component manufacturing sector component manufacturing sector is the sufficiently complex and demanding as to demand a complete control, efficient and very reliable of all the processes, and more taking into account that we are speaking of series relatively short with different ranks of product”. On the other hand, the implantation of Disgust in diverse plants of production required a system that allowed the communication between diverse places and in different languages, a “multisite, multitime zone, multilanguage Neither, Fr, Eng”. On the other hand, Disgust has to take into account different parameters regarding the maintenance, divided in three sections as they are the management of the functions (that it includes the general organisation, the maintenance properly, the relation with the production and the system of management in himself); the methods of work (the dysfunctions during the process, the predictive maintenance, the management of work, the monitory of the external provision and the monitory technician of the equipment); and the context of work (that it includes the workshop of maintenance, the RRHH internal and the purchase and management of pieces of spare).

On the other hand, the extensive park of machines of Disgust sues a “milimétrico” control of the cycle of life of the machines, with a conscientious forecast of his obsolescence, unemployed planned of maintenance, repairs, etc. And the CMMS of Carl adapts to almost all the specifications required by Disgust, “being an ergonomic tool to know the ‘state of the machine', an important support during the phase of implantation and total availability of the provider to give answer to the demands of the company”. Between other advantages that the system of Carl will contribute to Disgust finds the reduction of failures, the work under the valid rule, availability to expand and improve the system, optimise the planning and improve the relation with the customer. Because the solution of Carl allows, on a standard system, the ‘personalización' of the applications and enter the specificities of the customer, inherent to the philosophy of Carl, to attend all the needs of the user. By means of the system CMMS the signature will have available all the complete information of the structures, machines and locations of Disgust, as well as a complete control of stock and of the costs of the machinery, inside a plan of implantation foreseen for the next years.

Permanently connected

The ‘modern life' has carried to the society to be connected from any place to any hour of the day. Carl Software has collected this experience in Carl Touch, a device that allows to obtain the information of the installations in real time and simplifying the administrative work of the operarios. It treats of an application GMAO mobile especially developed for the technicians of maintenance that works in smartphone or tablets. A solution recognised in 2013 with the first prize Bemas to the innovation in the section of novelties for the sector of the industrial maintenance and that his managers presented also during the presses conference.

Between other advantages, Carl Touch solves the problematic of the incomplete reports and inexplotables thanks to his multimedia possibilities, that associate of native form the recognition of voice, text, photos, videos and recordings audio. Besides, the application always is available even without network 3G or wifi. In what it detects an available network, the informations synchronise of transparent and safe way without intervention of the technician. Carl Touch can use from a smartphone Android or a tactile screen and installs without technical intervention: it suffices with scanning a bar code of installation. With this application, the technician always is in relation with the his technical office and can request an assistance (call of an expert, visualisation of the technical diagram, documentation, etc.) as well as manage alerts and messages.

Such as it could see in a video demostrativo, Carl Touch allows that the operator have at all times the most updated information of the team to inspect as well as the evolution of the previous operations, allowing a preventive maintenance more effective and access to the last analyses, diagnosis of machines, etc. keeping informed the technical office in real time.

After the presses conference Disgust organised a visit to the installations, where the visitors could check that they still have in operation one of the first Mandelli installed and that “is arriving already at the end of his useful life”. Thus They Are posing the best options, if reacondicionar the machine or renew it definitively. In this sense, Nathan Dewinter commented during the visit that the CMMS of Carl will supervise the equipment, his useful life, unemployed programmed, etc. but no the tools used, that control by means of an own system and very specific. Between these tools find marks of first line like Walter Tools, Dry or Sandvik, adapted for the work in titanium, alloys, aluminium and steels that use in Disgust.

His installations in Zaventem, delivered in 8 plants of production, include also a system of dimensional control to fulfil with the minimum tolerances that demands the sector as well as spaces for the thermal sensors and superficial treatment like polishing, electrograbado, fosfatado and painted.

In the installations of Disgust can find from machinery Mandelli with a lot of years to his backs until new Makino recently installed.