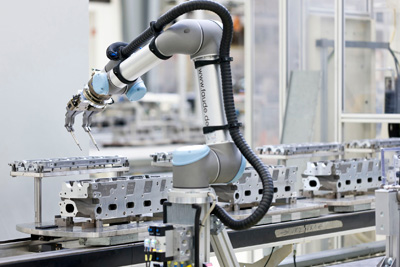

Way of Integrated hygiene: The first robot collaborates directly with workers of the plant of production of motors in Salzgitter (Germany)

Volkswagen Bets by Universal Robots for processes of ergonomic work

The group manufacturer of trucks Volkswagen has integrated an industrial robotic arm of the Danish manufacturer

The factory of Volkswagen in Salzgitter, with a surface of 2.800.000 square metres, is one of the greater plants of manufacture of motors of the world. Some 6.000 employees manufacture there near of 7.000 motors of petrol and diesel in more than 370 versions each day. The motors of 3 to 16 cylinders install in the distinct models and marks of the group Volkswagen. The manufacturer of trucks has installed recently an industrial robotic arm colaborativo of the Universal Danish manufacturer Robots beside the personnel of the section of setting of butts of cylinder of the factory with the end to insert sparking plugs of incandescence in the butts of cylinders.

Thanks to his way of hygiene integrated (according to the norm IN ISO 10218), the industrial robot can work next to the people. The robot is instrumented with a pinza colaborativa, designed by the integrador of the systems Faude Automatisierungstechnik in scoop for Volkswagen and that fulfils the requirements of the norm of hygiene ISO/TS 15066, the standard specification for the robots colaborativos. The robot has been able to integrate like this in the line of production without need of an additional protective cage.

“Want to avoid the loads on a long-term basis to our employees in all the sections of our company with an ergonomic disposal of the place of work. The use of robots without protective fences allows to the employees work hand manually with the robot. Of this form, the robot turns into an assistant of production in the process of manufacture and allows to free like this to the personnel of works desfavorables from the ergonomic point of view”, explains Jürgen Häfner, boss of projects in the plant of Volkswagen in Salzgitter.

The project is the result of a period of two years of narrow collaboration with the partner distributor of Universal Robots, Faude Automatisierungstechnik. Now the two employees of production commissioned previously to install the sparking plugs in the butts can work more comfortably. Up to now they had to insert the sparking plugs from a posture bent in the threaded orifice of the little visible butts.

Hand manually with a mate robot

Now the light robot UR5 of six axles of Universal Robots commissions of this task. The robot collects with care the delicate sparking plugs, supplied by a system of separation especially designed, and enters them in the threaded orifices of difficult access. An employee commissions afterwards to fix the sparking plugs and isolate the butt, something necessary for the following step of the production. Thanks to the direct collaboration with the robot, that acts like assistant, the employee can realizar these activities from a posture heaved and healthy. In the meantime, it can keep a constant surveillance of the process to be able to take part quickly in necessary case.

“Are loved with the success in the implantation of this unprecedented project and with the fact that our robots can contribute to some processes of work more ergonomic”, affirms Thomas Visti, vice-president and commercial director of Universal Robots.

“This has been able to achieve especially thanks to the constructive collaboration oriented to the results between Volkswagen and our partner Faude Automatisierungstechnik”.