Current resources to automate movements

Sure enough, the automate the productive processes is our challenge, do that our processes are more efficient, that include fewer human factors, that allow processes of flexible manufacture, tolerantes to changes of models or specifications, that at the same time the changes of models or specifications are fast and with low risks of failure, that the own process of manufacture involve control of quality and a long etc.

In the present article go to define the basic points that help us to incorporate to machines and processes all the current resources of movement of axles. All this fruit of the experience accumulated in the department of Mecatrónica of Larraioz.

1) Concepts

Define ‘to automate movements' to the task to displace a mechanism, do it rotar, situate it in a determinate zone with some determinate conditions, endow it of a speed function of any another parameter, realise a determinate strength or the combination of two or more than the previous factors.

To) By source of power used differentiate: pneumatics systems, hydraulics and electrical.

b) By type of movement can detail the following: linear, newspapers or the combination of both.

c) Like way of operation can do two big groups: servosystems and systems of open bow.

In this article will centre us in the definition of systems of electrical movement (point b) and servosystems (point d). Electrical as they are those that contribute the flexibilities of positioned necessary inside an energetic saving (see point 8) and servosystems as they are the only that guarantee the execution of the movement inside the parameters required. All our systems pose realimentación so much of speed as of position and optionally of strength.

2) Types of accionamiento electrical according to his technology

To) The rotary presses systems are the most known, and base in doing rotar a magnetic field to drag of this form an axis and produce his rotation. The most employed types of motors are step-step, synchronous of CA, synchronous of CC and asynchronous.

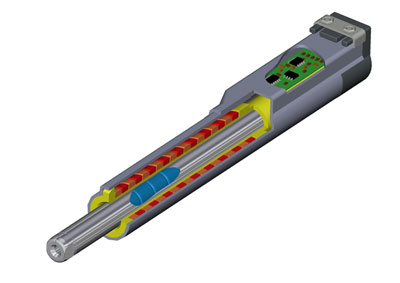

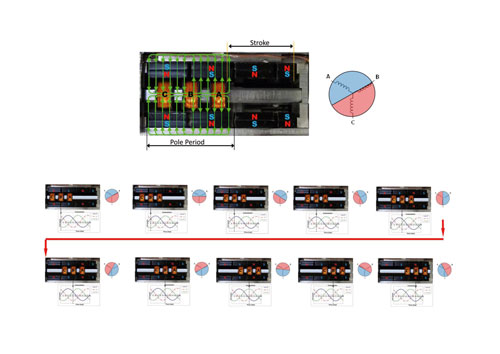

b) The linear systems intrinsically are magnetic systems that base in the trip of a magnetic field during all the route, dragging of this form a sliding or a vástago. By his conception can differentiate the systems that do to move the coils and keep the fixed magnets and those that move the magnets keeping the fixed coils.

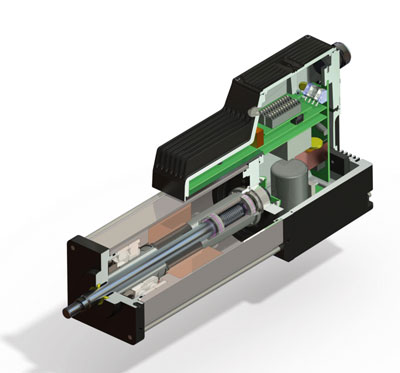

c) The systems pseudolineales are systems that produce the linear movement from a rotary presses movement and a mechanical transmission, typically are motors step by step or synchronous and a husillo or zip.

3) Types of accionamiento electrical according to his constructive characteristics

to) rotary presses Systems with axis, are the most usual and usually have of an axis of length and clear-cut diameter where join up the load, there are them with smooth axis or with chaveta.

b) Rotary presses systems gaps, also called motors of pair, characterise for having of a space in the radius of the engine that allows his direct setting in the axis of machine, avoiding of this form the use of transmissions.

c) Linear systems without guides, can be intrinsic linear systems or pseudolineales, but in both cases do not allow distinct loads to the one of steering of the movement (axial).

4) Parameters to define a process to automate movements

to) Characteristic mechanical, size, weight.

b) Cycle of work, ‘dutty cycle'. Usually defined like the time of operation with regard to the of rest, 100% of ‘dutty cycle' would mean an operation guaranteeed of continuous form. Although being rigorous this factor gives for the case in that the engine realises his maximum strength, with what a ready system to work to 50% ‘dutty cycle' could work continuously to the half of his diet of maximum load.

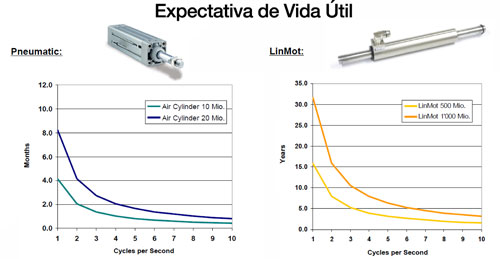

c) Useful life, measure in hours of operation, cycles of work or kilometres visited for linear systems.

d) Degree of protection, according to the environingingment of use the systems can define with normal protection (degrees of IP40 to IP55), for clean environingingments (IP69K for example) or ‘explosion Proof' (Atex in his distinct categories).

5) specific Parameters to define rotary presses movements

To) necessary Pair of continuous form, pair hammer necessary.b) Type of attachment, of hollow or conventional axis.

c) Necessary revolutions and necessary pair, or better a curve of speed/pair. According to the type of engine step by step or asynchronous, the pair can vary in all his rank of speeds of operation, thus it is very important this definition.

d) Acceleration and deceleración required, for high accelerations and deceleraciones require systems of low inertia, by what typically the inertia of the rotor has to define according to the application, like example an engine of high inertia in rotor is adapted for a husillo of machine tool, but no for an axis of high dynamics.

And) Resolution and precision of the system, that angular resolution is necessary and that precision. This defines the system transductor necessary and many times the type of engine.

6) specific Parameters to define linear movements or pseudolineales

To) Does fault a system guided? Such as before it commented if this is the case it is necessary to take into account the radial pair that will apply him .b) Maximum route, the routes define many times the type of accionamiento since for example a system type vástago is not usual in routes of 1 metre or upper.

c) Strength to exert axially, usually defines the power of the accionamiento. It is convenient to define as in the case of the newspapers, of the curve pair/speed, since in the case of the intrinsic linear systems is important to check the parameters of thermal sensors dissipation.

d) Form of setting. Horizontal or vertical, the use of systems in vertical position requires many times of the optional utilisation of brake.

And) Weight or load that have to bear the guides, valid only for systems guided.

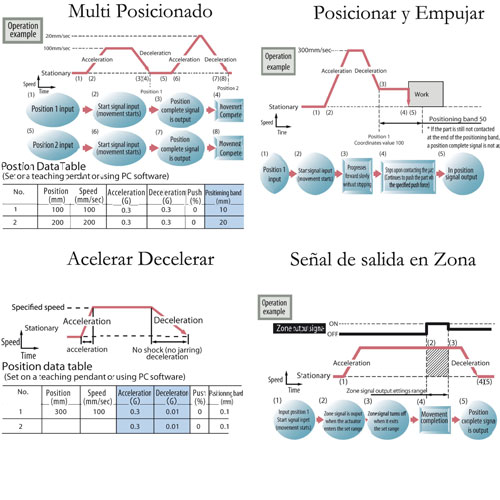

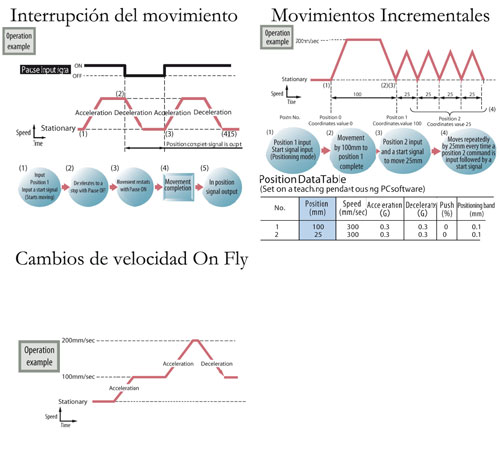

7) Parameters that define the functionality of the process and available tools

- Move a tope of a position to another like reaction to the change of an entrance and a confirmation that the tope has moved by means of an exit.

- Move an element of palpation until a determinate position, apply a determinate strength (for example to compresses a dock) and measure the position reached once realised the strength.

- Insert a buje or rolling controlling forces speed and position

- Realise a ‘lincado electronic' between two or more axles defining a curve of synchronism of free form (levy electronics equipment dealers equipment dealers)

- Move a sliding from speed and position 0 until ‘reaching' (synchronise) with a product that moves in a strip with a variable speed

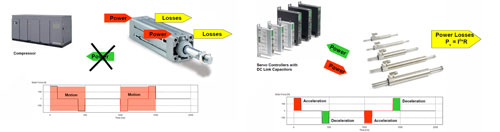

8) energetic Considerations

Of 100% of the power consumed:

- 50% of the power loses in the own compressesor of air, because of different factors like the own energetic losses of compressesion of air, the losses of the engine of the compressesor, the losses of the cycles of course-unemployment, …

- 16% of loss of power in the different valves of reduction and adaptation of pressesure.

- 5% of loss of power in the air treatment, filters, …

- 15% of loss of power in the own pneumatics actuator.

The pneumatics cylinder obtains the power through the pressesure of a discharge of air compressesed on a émbolo. All the phases of the movement —acceleration, constant speed and desaceleración— consume power produced by the compressesor from electricity. The difference of power between the consumed and the produced in the movement translates directly in losses, since the pneumatics systems can not give back power to the compressesor. Instead, the electrical actuators use the power directly of the electrical network with a high degree of efficiency, consuming only in the phases where really there is work, that is to say, in the phases of acceleration, and besides giving back to the controller the power produced in the phases of desaceleración.

If we want to displace the mass of 15 kilos a route of 400 millimetres in 500 metres will need to reach a speed of 1 metres by second, what results us in a pneumatics cylinder of 50 millimetres of inner diameter like minimum. Each cycle results us in a volume of air of 10 litres, and supposing 8.000 hours of operation year, will have 24.000 cubic metres of air to 6 annual bars (145.000 cubic metres of air to 1 bar), some 25.600 kWh of power consumed, or, what is the same, 3.072 annual euros of cost of electrical power to keep this pneumatics device in operation.A solution type with linear engine of LinMot results us with a power of inferior engine to 100 W, an annual power consumed of 800 kWh, and an energetic bill of 98 annual euros.

But no all the profits come derived of the energetic saving. Increasingly the manufacturers of trucks, pioneers in standardising the processes of manufacture still with frequent changes of models, opt for avoiding the uses of pneumatics systems, since this technology is hardly controllable, is dirty, and does in general of the machines something more rigid and difficult to configure.

9) Expectations of life

Inside the context of important international agreements like the Protocol of Kioto, of the cual Europe is one of the main impulsores, the reduction of broadcasts of CO2 has turned into a political and public priority. The production of CO2 of the producing plants of power depends of the primary fuel employee and of the factor of efficiency of energetic conversion. It is evident the bet of the European governments by the means of production of power less contaminantes and begin to proliferate the wind and solar parks, the head offices of cycle combined, etc. But to day of today there is a lot of work for doing and the power produced by the head offices of fuels fossils supposes a really important fraction, arriving in some countries of the Europe of the 15 to surpass 90% of the total. According to data of the Frauhofer Institut (Germany), for a factor of half energetic efficiency of 0,39, find us with some broadcasts of CO2 between 515 grams and 890 grams for the generation of 1 kWh of electricity from head offices of combustion of natural gas and head offices of combustion of coal respectively.