Factores a considerar al adquirir un robot

Director de Robótica en Husky Injection Molding Systems15/06/2003

Robotización

La carrera

El peso de la pieza

Más importante que la carga útil es el par, la tendencia de una fuerza a producir una torsión y una rotación en un eje, y es función tanto de la carga útil como de la distancia de ésta al punto central de la mano de agarre del robot. Para asegurarse de que un robot puede manipular una pieza, hay que comparar el par aplicado, el de la pieza y la mano de agarre, con el par que el robot puede soportar.

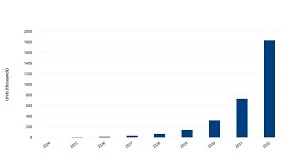

¿Cómo se evalúan las prestaciones? Las prestaciones de un robot muchas veces se presentan en términos de picos de velocidad. Pero esta información no es completa, a no ser de que se conozcan las aceleraciones. Por ejemplo, la figura 1 muestra las velocidades de dos robots, uno con un pico de velocidad de 4 m/s (arriba) y el otro con 3 m/s (abajo). Se podría concluir que el robot más rápido es aquel que tiene un mayor pico de velocidad. Sin embargo, ambos robots pueden recorrer la misma distancia de 2800 mm en el mismo tiempo, un segundo. Esto es posible porque el robot con menor punta de velocidad tiene una mayor aceleración (45 m/s2) que el otro (13,3 m/s2). Es más útil conocer el tiempo que requiere un robot para recorrer una distancia específica, una información que debería proporcionarla el fabricante.

Facilidad de manejo y fiabilidad

En cuanto a la fiabilidad, es interesante hacerse con componentes digitales como un controlador basado en PC con servomotores y accionamientos digitales. Como en cualquier otro equipo siempre puede haber algún fallo, por lo que conviene fijarse en la garantía, que varían mucho. Al valorar una garantía es importante fijarse en la lista de elementos sometidos a desgaste que están excluidos de la cobertura. Teniendo en cuenta las diferencias entre unas garantías y otras, una de tres años no siempre tiene que ser mejor que una de uno.

Los robots están sujetos a las disposiciones generales de la industria en lo que respecta a la seguridad y, en el caso de los robots para inyectoras, también les afecta la normativa relativa a este tipo de máquinas.

Conviene informarse también de este tipo de cuestiones, sobre todo las relativas a los puestos de trabajo, la instalación de limitadores mecánicos, elementos de seguridad en la zona de la caída vertical y otros.

El precio, por supuesto, es uno de los factores decisivos, que muchas veces determinan la compra, pero es muy importante tener en cuenta su impacto financiero en un sistema general. Por ejemplo, hay que tener en cuenta los ahorros que se pueden obtener reduciendo los tiempos muertos o aumentando el tiempo de ciclo.

Por poner un ejemplo, en una fábrica con 6.000 horas de producción, un 1 por ciento de reducción en los tiempos muertos del robot en una inyectora de 1.800 toneladas, puede proporcionar un ahorro de hasta 8.800 euros anuales, mientras que una mejora en 0,5 segundos en el ciclo en un ciclo de 10 segundos y una máquina de 200 toneladas puede aportar ahorros anuales de 12.300 euros.

En determinadas aplicaciones compensa sin duda la compra de un robot de las máximas prestaciones.

Antes de acabar es importante señalar que el robot es una parte de una línea entera de inyección: sus prestaciones, fiabilidad, seguridad y coste juegan un papel importante en el sistema en su conjunto. Por lo tanto, el robot que se elija debe responder a los objetivos planteados para todo el sistema.