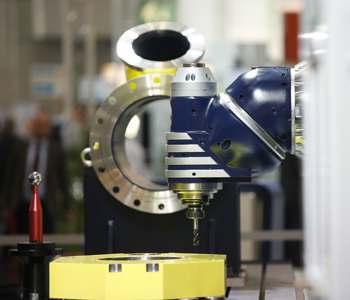

The Metav 2014 served of shop window for the guarantee of the quality inside the frame of the ‘Route of the quality'

The metrology is not it everything, but without the metrology... At all it is at all

The contribution of the current metrology the resume of succinct form Stephan Greulich, boss of Sales of Diatest Hermann Költgen GmbH, Darmstadt: “In the systems metrológicos, the information generated is of vital importance to guarantee the quality, and therefore, for the own product. To guarantee that this information fulfils with the stipulations of 'Industry 4.0' regarding the adaptability or efficiency of resources, no only has to be purchased of fast form, but it also has to interpret and translate immediately in the suitable action”.

Like all the processes involved in operations of production, comments, the elements metrológicos also have to integrate in the network of information that depending on the data of process and the stipulations entered, or formulate options for the taking of decisions for the operario human or modifies the processes of production of autonomous form. Nevertheless, the following industrial revolution, affirms Greulich, “still is a bit far”. Industry 4.0 is until the moment a word that connotes crowd of intentions and even more expectancies".

To what adds that, of course, is perfectly possible to transfer the data measured by wire or radio to terminals or portals Web, in reference to Industry 4.0, “however, even in the best of the cases treats of a provisional solution. It is not ‘intelligent' in the sense of shrewd or smart, since the data measured are simply transmitted, but no necessarily gives place to an action (in network)”.

The Metav 2014 had like axis the Industry 4.0.

The simulation does not substitute the practical proof

To achieve and evaluate the data measured exist in the diverse actuality solutions of software. However, still it is “the human being the one who takes the decisions in base to the data evaluated by the software and whose stipulations in the software will control of suitable and automatic form the process of production”.

The expert also contributes an impartial assessment concerning the importance of the technologies of simulation for the optimisation of processes: “The technologies of simulation very planned and very thought can substitute, at least the some cases, adjust them of comprobación and the proofs. However, never they will substitute to the final proofs of the optimisation of process in the real practice, since in the majority of the cases the reality will be more complex of what can imagine in a simulation”. Greulich Sees the forum ‘Route of the quality' of the Metav like a platform of basic information on the last tendencies and developments of the guarantee of the quality. Also it would be interested, besides, in achieving more information on the expectancies of the visitors of the fair.

The importance of the speed and the ease of use of the operario

Heinrich Leutenberger, subjefe of Vicivision GmbH, Heilbronn, has the same opinion: “The technology metrológica current can guarantee fast and precise information concerning the dimensions and to the characteristics of other products. A process of stable and effective production only can attain with this type of information. Being east the context, the speed and, in particular the ease of use of the operario are crucial, because this information also has to be available without the skilled experience”.

“Of course”, adds, “in the production on a large scale (the industry of automotive sector, for example), there are some approaches that involve technology metrológicas intelligent and of proof through portals or applications of intelligent telephones, but still does not form part of the dimensional metrology, because the cost still is not justified by the number of possible applications".

In the dimensional metrology, the technicians of simulation still do not play a significant paper in the optimisation of processes. According to the, unfortunately the potential of the capacities metrológicas current still is not being used to the one hundred by one hundred. According to his estimates, is because of the unsuitable knowledge of the base metrólogica, and the continuous reservations by part of the small and average companies, that tend to think that the substantial investment in the technology metrológica would have to avoid - “can not obtain profit from here...”.

From the forum ‘Route of the quality' in the Metav 2014, Leutenberger like exhibidor expects “especially, that the visitors have found it interesting and perhaps do an idea of how can use the technology metrológica current”.

The present and future of the sector of the metrology go through the quality and the precision.

Intuitive and intelligent, an approach resolutivo that promises

A transparency improved and a measurement and a speed of upper reaction in the systems of guarantee of quality of the future is what Andrzej Grzesiak, boss of systems metrológicos in Carl Zeiss Industrielle Messtechnik GmbH, Oberkochen, wait of Industry 4.0 “with the digitalisation by a side and the use of the interfaces of the current machine, by the another”. Because of the increasingly high levels of complexity, “without the technology metrológica current and the technology of comprobación, is not possible to obtain an aseguramiento of the quality adapted”. The request is every time greater to adapt the surroundings of turbulent production involved: “Independently that they are the intuitive interfaces of the operario those that adapt to the human needs or the machines metrológicas intelligent, Industry 4.0 is definitively the approach resolutivo promising for the future”.

The influence that Industry 4.0 is exerting on the development of the equipment metrológico in the operation of industrial production explains it his colleague, Dietrich Imkamp, boss of Visual Systems & Partner of Carl Zeiss Industrielle Messtechnik: “The processes of industrial production of all the world, in which there is a continuous tendency to a high quality of product, characterise by some chains of production interrelated to global level. Being east the context, the exchange of information to guarantee the quality purchases an every time greater importance”.

The expert also is quite optimistic regarding the options that depend of the process for the implementation of an aseguramiento of the near quality to the production in near surroundings to the production based in Internet, using applications of intelligent telephones, for example: “The technologies that result familiar to the surroundings of the consumer will go in into use, beyond all doubt, for the aseguramiento of the quality also in the surroundings of the manufacture. In this context, however, will have to fulfil with a series of special requirements, for example, in terms of dependency and hygiene of transmission of data”.

In the field of the metrology coordinated also the information organised and the management of the communication go assuming progressively greater importance. To such end, require some technologies in which they organise the machines, the programs, the logos and the knowledge in a central location. Nevertheless, the majority of the portals of knowledge and the systems of management of documentation are too global, without any option optimised for the technology of measurement coordinated. In this point, the best option is the safe access, the solutions based in the server for the intranets of the company, through which can realizar from repairs until an intuitive operation and that they are simple to administer.

The intelligent systems help to the monitoring of the quality

In the actuality, adds Andrzej Grzesiak, a company of manufacture “has to be able to face up to the changes. Thanks to the standardisation of the processes of quality and to the use of tools of software, can attain an upper degree in the modularización of the technology metrológica and of comprobación. The intelligent systems process data of form decentralised and are able to support to the personnel in the monitoring of the levels of quality. No only it treats to dream in terms of futurología but it is a real fact in the actuality”.

Because of the high degree of automation that has incorporated to the operations of current production, the quality of the data measured and of production follows increasing. With the end to obtain the maximum profit of this abundance of data, require solutions of flexible system like the systems of management of data of quality that provide an evaluation harmonizada and an analysis of the data of measurement and process. Like appointment Andrzej Grzesiak: “The virtual technologies like the tablets or the glasses of data are the tendency of the future. Besides, with the help of the virtual technologies, can develop systems of effective help that do that the technology metrológica was increasingly intuitive, more transparent”.

The tactile measurement is one of the most used methods to purchase of reliable form the form and the state of the edges of cut of the tools of big precision and do that the data are available for the process of mechanised with the end to attain a greater optimisation. This task of measurement, comments Grzesiak, “is at present restricted mainly to the optical systems that work in the planar way, due to the fact that the speed so much of handle as of measurement are every time better. The tactile methods win in terms of quality relatively reliable of the data measured, independent of the characteristics of the optical surface.” But in the field of the metrology, the human factor also plays a fundamental paper. This is the reason by which the machine of measurement, like instrument that ensures the quality, has to provide active and intelligent support to the operario.