A4S es una solución ideal para lograr una clasificación automática, sencilla, flexible y productiva de piezas cortadas en maquinas de corte 2D

Automatización ‘inteligente’ aplicada al proceso de corte 2D

Patentado, flexible y productivo, A4S es una innovadora solución FMS (Sistema de Fabricación Flexible) para la carga y descarga de sistemas de corte 2D, capaz de seleccionar y apilar diferentes materiales, independientemente del tipo de nesting. Ha sido desarrollado por Astes4, una empresa con sede en Suiza que reúne las experiencias profesionales más cualificadas en el campo de la automatización industrial, diseño mecánico y el desarrollo de software. A través de su representante Laraudogoitia Maquinaria Industrial S.L., Astes4 ofrece A4S.

Los procesos industriales cada vez son más rápidos con lotes de producción cada vez más pequeños y orientados a la reducción de stock. La gestión de la producción requiere un sistema flexible y fácilmente adaptable a los cambios rápidos de producción. Con el fin de apoyar la competitividad global, la reducción de costes sin tener en cuenta los riesgos de deslocalización, la empresa ha de disponer de sistemas de producción eficientes e interconectados con el sistema de gestión. En la práctica, un control directo entre los departamentos facilita la cadena de toma de decisiones.

En el mundo del corte de dos dimensiones de chapa donde hay una necesidad de una fabricación flexible, controlada, ordenada y trazable, la empresa Astes4, a través de su representante Laraudogoitia Maq. Ind. S.L, ofrece su novedoso sistema ‘A4S’, la combinación de las tecnologías más avanzadas en el campo de la manipulación y picking. Hablamos de sistemas de automatización, carga y descarga ‘inteligente’ para sistemas avanzados de corte 2D.

4 manipuladores y 16 ejes

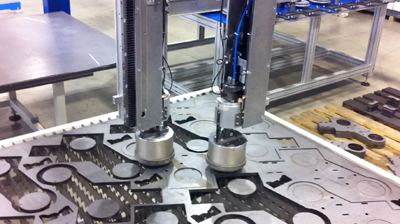

No importa si el sistema de corte es de láser tipo CO2 o fibra, chorro de agua, oxicorte, plasma, … A4S ha sido diseñado y desarrollado para seleccionar, manipular y apilar diferentes materiales, independientemente del nesting de corte de materiales ferrosos y/o no ferrosos. Inteligente y sin supervisión, A4S consta de una estructura mecánica de doble portal en la que hay 4 manipuladores. Un sistema capaz de coordinar los 4 cabezales accionados de forma independiente o sincronizada. En cada pórtico se montan un par de manipuladores gestionados y optimizados de manera eficiente gracias a un software, que coordina la máquina de corte, el pórtico A4S y el almacén automático de chapa.

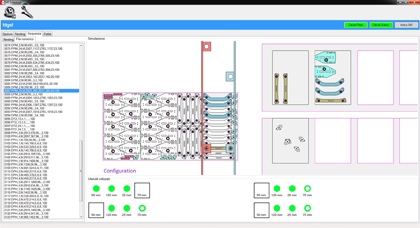

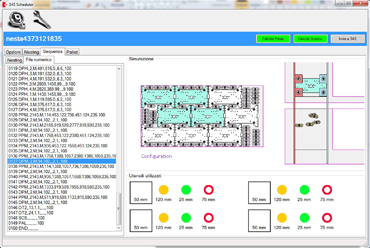

La elección de la herramienta (o herramientas), los puntos de cogida de la pieza, y el lugar de depósito en el área de almacenamiento están totalmente automatizados. La composición del almacén de herramientas es configurable y coordinado por el programa de nesting, así como la siguiente secuencia de cogida y de descarga.

Las herramientas disponen de un sistema de enganche rápido, capaz de garantizar la flexibilidad necesaria para descargar y apilar fácilmente cada tipo de pieza, resolviendo así las limitaciones de los sistemas de automatización comunes. Dependiendo del tamaño de las piezas y la velocidad del flujo de trabajo, el sistema selecciona con total autonomía la mejor y más eficiente solución para el uso de 1 a 4 manipuladores. Es importante tener en cuenta la capacidad de uso combinado de herramientas con ventosas y electroimanes. De hecho, con este último se logra alcanzar una capacidad de carga de 12 kg/cm2, significativamente más alta que la lograda con las ventosas de 0,5 kg/cm2.

El software de programación permite el ‘control activo’ de la complejidad geométrica de las piezas, su peso, su espesor, la identificación precisa de su centro de gravedad. Todo esto permite garantizar la extracción correcta de las piezas cortadas incluso con la combinación de los cuatro órganos de sujeción.

Máxima flexibilidad productiva

El sistema A4S es integrable con todos los sistemas y soluciones en el mercado de las máquinas de corte y almacenes de chapa (no hay diferencia operativa si se trata de maquina nueva o ya existente), el sistema está diseñado para capturar archivos en los formatos más comunes (ISO, DXF, DWG, etc.) generados por sistemas CAD/CAM.

Otro punto fuerte de A4S reside en la capacidad de aprender y adaptarse a la lógica de producción, adaptando su velocidad de carga y descarga a la velocidad de la máquina de corte. Esta interacción dinámica, permite un menor desgaste del sistema mecánico con ventajas evidentes para la duración de la vida de los componentes y la consiguiente reducción en los costes de mantenimiento. La mayor velocidad de A4S frente a la máquina de corte, permite integrar otras operaciones, tales como el marcaje/etiquetado para la identificación de las piezas descargadas.

Además de la productividad de los ciclos de carga y descarga sin supervisión y la optimización de los espacios por la compacidad del sistema, A4S ha sido diseñado con una clara orientación ‘verde’ capaz de garantizar un ahorro tangible de los costes de consumo de energía.

Respecto a la gestión de retales, las piezas cortadas quedan completamente separadas, todo el retal se descarga con el peine o se puede cortar en pedazos y descargar en contenedor. También se puede separar automáticamente los materiales para su reciclaje.

Tampoco hay que subestimar el aspecto del menor espacio de maniobra necesario para los medios de manipulación y el grado de sostenibilidad debido a algunos dispositivos tecnológicos realizados: Bajo consumo de energía mediante el uso de electroimanes permanentes, muy bajo consumo de aire comprimido, el sistema de ahorro de energía que permite el reposo del motor si ha de permanecer inactivo por un tiempo prolongado mientras se espera al próximo proceso.

La eficiencia de la producción debe ir de la mano con el proceso de corte y, por esta razón, la propuesta del sistema A4S se realiza a medida para cada aplicación específica. Ello significa compartir con los clientes sus necesidades operativas reales, realizando el estudio de la distribución y la optimización del flujo de procesos. La meta no es vender sólo un sistema sino más bien ofrecer un valor añadido en términos de aumento de la productividad y, por lo tanto competitividad, entendida en su sentido más amplio.

Máquina desatendida, con total seguridad

A4S es capaz de operar en modo no presidido, lo que significa que la programación del corte se puede ajustar en tres turnos, con un beneficio económico evidente de un aumento de la capacidad de producción y el consiguiente aumento de la competitividad operativa. Un modo garantizado por los controles de funcionamiento y seguridad para evitar el potencial error humano en el manejo del material a cortar. Los sensores de abordo están programados para detectar situaciones de alarma y gestionar la información derivada de los cortes no conformes (no detectado por la máquina de corte), evitando así el desperdicio de materiales y recursos. El sistema también se interconecta con la gestión corporativa del cliente comunicando que algunas piezas no se han descargado por defectos de fabricación durante el corte como un ejemplo, cuando las piezas se ‘sueldan’ en la parrilla.

El resultado cobra alcance con la eliminación de errores de paletizado, la reducción de residuos, errores de conformidad, derribando sus costos de operación, sino también mediante la optimización de los movimientos internos y la reducción de los residuos de materias primas y/o semielaborados no gestionados. Un enfoque que le permite promover la reducción de los lotes de producción, en línea con las demandas actuales del mercado, para reducir los tiempos de espera hombre-máquina, en línea con la visión de just-in-time. Y, al mismo tiempo, para garantizar una supervisión constante del proceso de corte.

Las ventajas de una cogida patentada

Tal y como se ha concebido y diseñado, el sistema A4S es capaz de utilizar herramientas magnéticas con capacidad de hasta 12 kg/cm2, además de ventosas tradicionales, en cuyo caso el caudal medio neto es de aproximadamente 0,5 kg/cm2. Los diferentes imanes llegan así a aumentar hasta 24 veces la velocidad de flujo, lo que permite moverse fácilmente y sin dificultad, incluso con chapas de hierro de gran espesor (hasta 30 mm), con alta concentración de agujeros, de formas complejas, y tiras largas estrechas que tradicionalmente no es tan sencillo de gestionar de forma rápida.

El concepto de utillaje con amarre intercambiable es el corazón tecnológico de la patente A4S. La combinación de un sistema de cogida eléctroimanneumático proporciona la flexibilidad necesaria para descargar y apilar diferentes tipos de piezas superando las limitaciones propias de los sistemas de automatización más comunes y tradicionales.

Job list eficiencia en sinergia

Para poder comprender mejor cómo el A4S puede ser muy eficaz y eficiente en la producción, es necesario entender el concepto de trabajo de la lista de trabajo (joblist). Gracias al software desarrollado, este permite concentrar los más diversos tipos y cantidades de piezas, materiales, pedidos de clientes, conjuntos, etc. El nesting CAD/CAM optimiza de forma independiente, realizando su mejor trabajo de optimización de superficies sometidas a corte.

El sistema realiza el almacenamiento bien organizado de cada pieza de trabajo y de los retales, de acuerdo con la lógica de la división ubicado tras la lista de trabajos. Esto significa que si un folio de chapa presenta zonas libres, en la misma se puede insertar automáticamente el mecanizado de una o más piezas ‘repetibles’ (que no pertenecen propiamente al lote principal en la producción), pero que, en este caso, dan valor a lo que de otra manera sería chatarra. Su gestión no es diferente al lote normal, ya que las trata exactamente de la misma manera, apilándolo como una pieza más.

La elección de la herramienta (o herramientas), punto cogida en la pieza, y el punto de depósito en el área de almacenamiento, están totalmente automatizadas, aunque se puede acceder y modificar estos datos de una manera fácil y rápida de acuerdo a las necesidades específicas producción El sistema A4S es una solución ideal para lograr una clasificación automática, sencilla, flexible y productiva de piezas cortadas en maquinas de corte 2D.