Reduction of costs in the production of electronic components

The current electronic devices have delicate pieces that need an accurate finishing by part of the manufacturer before being able to them incorporate to the final product. These components have to protect against the dirt, the humidity and the corrosion to guarantee that they work properly, and have to carry a plate of with bar code —usually a label autoadhesiva designed specifically— for ends of identification and autenticación that last all the useful life of the product. These tasks of posproducción are essential, but very laborious and expensive, and often involve an activity of manual setting, especially in the case of the smallest components.

An integrated cheese cheese solution

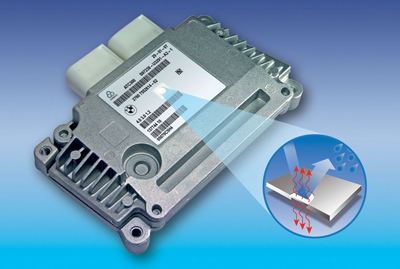

Schreiner ProTech, a unit of business centred in systems of labeling autoadhesivo of last technology of the Schreiner Group, Oberschleissheim (Germany), has found the answer. The company has developed an integrated cheese cheese solution that combines a stamp of compensation of pressesure and a plate autoadhesiva durable in one same contraencolado that supplies in shape of coil and can apply of automatic form or manual in the electronic component. This contraencolado special does not affect for nothing to the performance of the stamp neither of the plate. On the contrary, the system provides a significant saving in matter of costs and time to the manufacturers of electronic devices of industries like the automotive sector, the electronics equipment dealers equipment dealers of consumption, the electrical devices and the sanitary ware sector.

Advantages of the contraencolado autoadhesivo

The contraencolado of the label autoadhesiva, that combines a material of surface, an adhesive layer and a protective layer estucada, is a versatile product with a lot of possibilities. The stamps of compensation of pressesure with integrated cheese cheese plate of Schreiner ProTech use a membrane impresa like surface, combined with an adhesive elected especially to improve the performance of the support of the component (metal, plastics of high and low superficial power like the HDPE and the polycarbonates). To guarantee a suitable ventilation of the stamp and the capacity of optimum impressesion of the label, to the adhesive layer adds him the technology BleedStop of Schreiner ProTech, that avoids that the thick layer of adhesive necessary for durable labels on surfaces rugosas or irregular go out by the edges of the label. The contraencolado complete with a protective layer of big reliability that goes revestida of silicone and allows to apply the plate and stamp at the same time in the support of precise way and flowed by means of an automatic or manual dispenser.

Norms and international homologations

Schreiner ProTech Collaborates closely with the customers to identify and fulfil concrete needs, included international standards like REACH, RoHS, IMDS, RAEE, UL and CSA. The message form in the plate of identification guarantees the hygiene and authenticity of the product, so his capacity of impressesion, durability and legibilidad (by means of a reader and also to simple sight) also are fundamental. The plates of Schreiner ProTech also fulfil this requirement, and can supply in shape of labels preimpresas or without printing so that it was the manufacturer the one who print them afterwards.

“A project of specific development”

“The development of this practical solution to save costs has been the result of a very specific project realised by a team of specialists of the company centred in giving answer to some concrete needs of the customers”, says Michael Spörl, boss of product of Schreiner ProTech. “It supposes a big contribution to the field of the production adjusted in some surroundings of production where there is a lot of manual intervention. Besides, we can supply the product to the customers with big rapidity, in any part of the world”.

Prize to the innovation

In the prizes to the labels