Robot autónomo para reparaciones en entornos peligrosos

El dispositivo, con una base de seis patas y un brazo semi-rígido, está orientado a grandes instalaciones de sectores como la energía o la construcción y a entornos peligrosos como centrales nucleares o plataformas petrolíferas.

Algunas industrias complejas como la de la energía, con entornos restringidos o peligrosos como centrales nucleares o plataformas petrolíferas, necesitan reparaciones y mantenimiento que representan un potencial peligro para los trabajadores. Otras, por lo intrincado de su diseño, requieren de un mantenimiento en lugares inaccesibles que no puede ser ejecutado por personas. Esto ha aportado un mayor grado de dificultad y nuevas necesidades a la hora de acometer reparaciones o, simplemente, para llevar a cabo labores rutinarias de mantenimiento.

Por ello, un consorcio europeo ha puesto en marcha el proyecto MiRoR, en el que participa IK4-Tekniker junto a otras siete universidades, empresas y centros tecnológicos en el VII Programa Marco de la Unión Europea, para diseñar un robot miniaturizado capaz de desarrollar tareas de reparación y mantenimiento con un elevado grado de precisión y flexibilidad.

Dadas sus características, el proyecto MiRoR está diseñado para aplicarse en sectores que requieren de grandes inversiones. Por un lado, sectores industriales relacionados con la energía, como las centrales nucleares o las plantas de extracción de gas y petróleo. Por el otro, las grandes obras de ingeniería civil. Además, el robot también tiene aplicación en sectores como la producción de grandes motores a reacción para el sector aéreo. Por eso, el proyecto cuenta con la participación de grandes empresas como Areva, Acciona, Petrom o Rolls Royce.

Se prevé que el proyecto, iniciado este año, culmine con el desarrollo del robot en 2015.

Alto nivel de precisión y flexibilidad

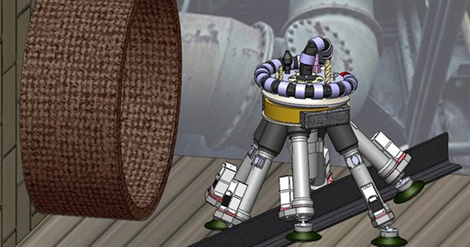

El robot está conformado por dos sistemas robóticos complementarios que le confieren un elevado grado de flexibilidad. El primero consiste en una base con seis patas con la doble capacidad para desplazarse de manera autónoma así como para llevar a cabo procesos de mecanizado de precisión mediante cinemática. El segundo sistema consiste en un brazo robot semi-rígido, que permite acceder a espacios muy estrechos. Gracias a su sistema patentado para conferir rigidez a los segmentos del brazo, el brazo robótico es capaz de llevar a cabo tareas de inspección y mecanizado en lugares inaccesibles.

La conjunción de los dos sistemas está controlada por un sistema de tres niveles: un control de bajo nivel para los procesos de mecanizado, un nivel intermedio para el movimiento del robot en el entorno de trabajo y un control de alto nivel que aporta la inteligencia al sistema.

El control inteligente permite al robot un amplio abanico de funciones de navegación, como la localización y la planificación local y global de itinerarios, así como la calibración en el mecanizado y la obtención de un posicionamiento óptimo de las patas del robot.

El robot también está provisto de sistemas que le permiten tomar decisiones sobre la mejor manera para acceder a su área de trabajo, así como su adaptación al conocimiento que obtenga en actividades de trabajo previas. Por otro lado, el robot está dotado de un sistema de auto-protección para situaciones en las que se encuentre en condiciones de peligro.

Para un óptimo rendimiento del robot, el sistema incluye un banco de pruebas virtual que permite identificar la mejor configuración del dispositivo para cada entorno industrial así como simular y predecir el comportamiento del robot frente a obstáculos y circunstancias imprevistas.