Intelligent systems of control and handle for inyectoras

Thus it earns vital importance the care of the productive process, with a special control of the parameters of adjust: temperatures, pressesures, time etc. This requires obviously of systems of intelligent control, PID car-adaptable and in general fast and precise algorithms.

As I complement to all this, the high cadences of production, do that the traditional hydraulics systems or tyres add costs of piece increasingly inasumibles.

Like this the inyectoras that pretend to cover the needs of this decade owe to take advantage of of systems of motion 100% electrical, so much for the enclosed - opening of moulds as for all the accionamientos auxiliary, extraction equipment equipment etc. Owe to endow besides with a system of control of high provision, where the systems embebidos offer enormous advantages so much by his specification as by his high capacities of computation and extreme speed of reaction.

Flexibility of adaptation to fast changes of format, mecatrónica

So much when designing an automatic line, as when structuring a process of control in a machine, the concept of flexible production has to be a priority. Two points have to take into account: the connectivity of the parameters and necessary orders by part of the gestión of production, and the adjust automated of profiles of movement and positions of topes, heights, forms or thicknesses. Centre us in this last section.

In an inyectora, nonios and adjust manual with manivelas can and have to replace by systems of positioned. Added to this, an efficient gestión of recipes will allow that the machines change of format with an effort and minimum time.

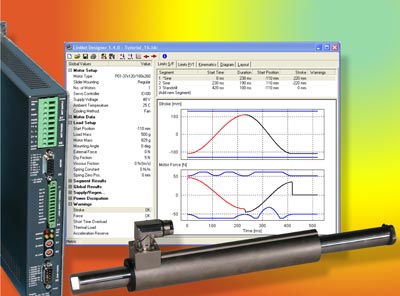

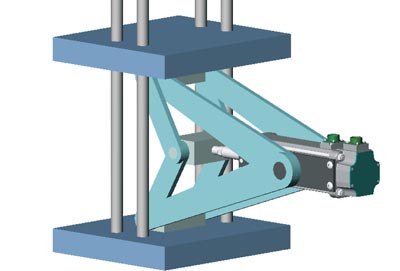

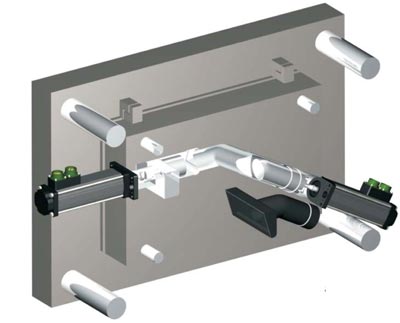

For this, the range of linear electrical actuators of Larraioz offers the simplest solution for the positioned of trucks, topes or any another mechanism that require well a pre-positioned or a movement during the process in himself same. Basically three families cover these needs: Robocylinder and MPC (multi position Cylinder) and EXLAR for applications of big strength.

The actuators RoboCylinder are destined equipment to the replacement of the pneumatics devices. Manufactured by the Japanese house IAI, the one who proposes an enormous diversity of models of electromechanical actuators (more than 3000 references) of wide utilisation in the process of packs and packaging of product.

These elements allow of an extremely simple form control the movement of a tope, a height, depth, etc… attaining of this form realise all adjust them of a line of automatic form, without manivelas manual, without rules, trasductores external, neither any another device of measurement or reading.

Changes of format, adjust in cycle or even movements of interpolation, are now so easy to realise like the installation of a cylinder or an electroválvula.

So much the operario of maintenance without special knowledges of axles or 'Motion', like the integrador of some lines of injection, can from this moment, install, configure and set up the systems of adjust automatic of line with scarce effort by his part. Without it adjust of complex parameters, without wired up of external sensors, without finals of career: the new 'RoboCylinder' allow to realise movements with maximum routes of until 3 m, repetitividades of positioned of 0,01 mm, speeds of until 3 m/s and adjustable strengths of until 2 tonnes.

Different types of controllers of IAI allow to configure easily a complex system of actuators, from simple orders of positioned until complex functions of relations between axles like commandos of robots cartesianos or Scara, or synchronisms with external devices like cameras of vision for execution of tracking of product. All this managed by means of simple digital signals or diverse buses of communication like Modbus, Profibus EtherCat or DeviceNet, among others.

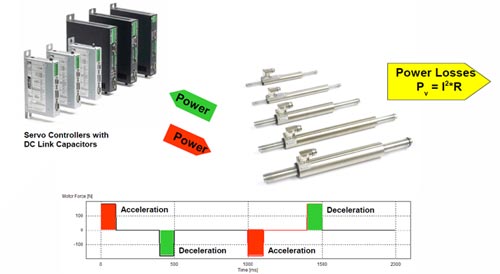

The devices MPC base in linear motors of the prestigious Swiss signature LinMot. Motors of vástago and independent stator, that do not carry any type of transmission between himself. Of silent operation, the linear motors MPC, are accionamientos electromagnetic linear, free of wear, without reductores intermediate, husillos or belts.

The engine consists of only two elements: the vástago actuator and the stator. The vástago composes of magnets of Neodymium mounted inside a tube of stainless steel of high precision. The stator contains the reeled, sensor of temperature and an integrated cheese cheese electronic card. This card controls the position of the stator by technology 'Sensor-Less' what gives a high repetitividad of until 0,05 mm without need of delicate transductores of position.

The design of the engine bases in an effect of magnetic levitation since the field produces in the 360 degrees of the stator. This besides caters to the system of an extremely dynamic capacity: upper speeds to 6 m/s and greater accelerations of 300 m/s2 (30G) without any type of mechanical transmission. The maximum routes reach the 2.000 mm and can develop strengths of 1.000 N.

His controllers facilitate besides the synchronisation of movements, what allows to realise of form very simple a portico in 'gantry', or a system of levy electronic, cutting to the flight, etc.

All these systems cater in group, regulatory + engine + cables, with distinct degrees of protection until IP69K, that do him adapted for the work in environingingments of big requests of estanqueidad and hygiene as they are the alimentary industries, pharmaceutical or chemical. Solutions of stainless steel fulfil the most demanding requirements of the different sectors.

The provision of LinMot do not finish in his actuators. The families of controllers B1100 and And1100 allow functions of control of movement such as positioned simple, programming of complete sequences of movement, axles Gantry, master relations-slave with other axles by means of levy freely definable, or streaming of position, position-speed or position-speed-acceleration. The different configurations of interaction go through the alternatives of control by means of digital signals, possibility of consign analog for position, speed or strength, or buses of communication like RSLink on RS232 or RS485, DeviceNet, CANOpen and ProfibusDP. The new family of controllers And12xx increases the provision of power of the linear motors, reduces the times of the bows of control optimising the gestión of the actuators, and incorporates new buses of Ethernet based in real time as they are EtherCat, PowerLink, Ethernet/IP, Sercos III, ProfiNet.

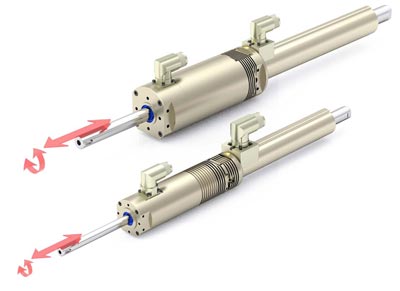

The actuators of EXLAR are the ideal electromechanical alternative to the hydraulics actuators, accionamientos electrical robust and precise that offer solutions of linear and rotary presses performance for applications of the industry of the plastic.

These systems allow to realise strengths of until 450.000 newton (45 tonnes forces) with greater efficiencies to 90%, that in comparison to values of lower efficiency to 50% in the hydraulics systems, represent the best option of replacement of hydraulics actuators-pneumatics by systems purely electrical of high dynamic, enormous length and high efficiency.

The American company Exlar, represented by Larraioz, offers a big variety of standard coatings of his products: steel, combinations of aluminium, stainless steel, anodizado anodizado, hard coating, electrolytic nickel and coatings epoxi. Also they provide the actuators and the motors to the customers with the specific layers to his needs. This can include the painting stipulated by the customer, electrólisis, revestimiento of teflón or a variety of other options.

Offer the option of coatings special allows to the products Exlar enter easily in the surroundings of his application, or coincide with the others components of his system.

The internal sensors measurement and control the current position of the engine and his temperature, his speed and the strength effected, no only at the end of the movement, but during the same. Like this the deviations of position, speed and strength detect immediately and transmit to the control. This guarantees a high level of hygiene in the operation and a reliable detection of errors. Since they do not exist components that can spend , can guarantee the most dynamic profiles of movement during all a dilated operational life.

The strict control of all the parameters of the profile of movement allows to guarantee a constant quality of the process of injection, as well as an efficient opening process/closed of moulds, without hits, faster, softer and with a radically inferior consumption to the conventional hydraulics.

Productive and energetic efficiency, useful life

The use of the power of an efficient way recortará of substantial form the costs of operation of the installation and/or machine, in addition to benefiting the environingingment. It is evident and essential a full convergence between the needs of development so much business, as of environingingment. The evolution of our company and the sustainable development have to go of the hand.

Is usual the use extensivo of pneumatics and hydraulics systems in machines inyectoras, cientos of cylinders can form part of the sequence of manipulation of product and container, without that seriously they pose the costs of the utilisation of this power.

So much the RoboCylinder like the MPC are devices designed with the key aim to substitute the traditional pneumatics systems. The linear actuators of IAI (Japan) and the linear motors of LinMot (Switzerland) use the electrical strength like only source of power of mechanical transmission. With these devices can realise operations so simple like which realises a pneumatics cylinder, displace a mass of a point to another, but the fact that they are systems servo-controlled will allow us have a total control of parameters of the movement such as the acceleration, deceleración, speed, strength, … in addition to infinite positions of destination, really complicated to achieve with the pneumatics solutions. Also we will be able to realise functions much more complex like synchronisations and interpolations between different axles, employ multiple buses of communication and protocols to send the sequences of movement, obtain a feedback of the current position and state of the actuators...

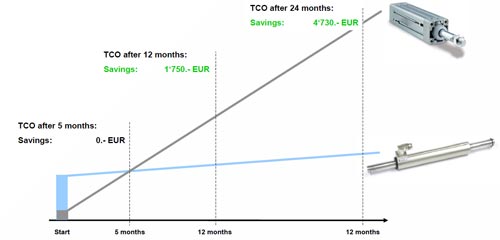

With the pneumatics systems, a compressesor works by means of electricity to generate the air compressesed necessary for said actuators. The air generated is supplied by means of a network of pipes and other circuits of transmission of the air to the cylinders and other pneumatics actuators. It is in these last devices where this power turns into a strength of linear movement. This group of mechanisms is subject to a substantial energetic loss.

According to the Technological Institute of Tokyo, the energetic efficiency of the pneumatics devices round 14%.

Of 100% of the power consumed…

• 50% of the power loses in the own compressesor of air, because of different factors like the own energetic losses of compressesion of air, the losses of the engine of the compressesor, the losses of the cycles of course-unemployment…

• 16% of loss of power in the different valves of reduction and adaptation of pressesure.

• 5% of loss of power in the air treatment, filters…

• 15% of loss of power in the own pneumatics actuator.

Besides, the systems of air compressesed always have escapes. At present a lot of installations suffer some losses by escapes that represent between 25% and 30% of the total consumption of the compressesor. An orifice of 1 mm of diameter in the circuit of air supposes an escape of 3,5 Nm3/h of air, one of 5 mm 85 Nm3/h and this to the current costs of electricity supposes a waste of 7.300 annual euros, without taking into account the environingingmental half deterioration that this produces, the cost in himself already is more than considerable.

With RoboCylinder, the revolutions of twist of the electrical engine newspaper convert mecánicamente in strength of linear movement by means of a system of transmission energetically efficient.

With MPC instead the own electrical power of the engine transforms in a linear work, not even there is a mechanical system of transmission of circular strength-linear. The energetic efficiency of both families oscillates between 80% and 92%, what comports some energetic costs of operation from among a third and a tenth part of what would suppose the energetic bill of the pneumatics systems.

The pneumatics cylinder obtains the power through the pressesure of a discharge of air compressesed on a émbolo. All the phases of the movement, acceleration, constant speed and deceleración consume power produced by the compressesor from electricity. The difference of power between the consumed and the produced in the movement translates directly in losses, since the pneumatics systems can not give back power to the compressesor. Instead, in the actuators of RoboCylinder or MPC uses directly the power of the electrical network with a high degree of efficiency, consuming only in the phases where really there is work, that is to say, in the phases of acceleration, and besides giving back to the controller the power produced in the phases of deceleración.

The utilisation of Hydraulics systems - tyres comports, in machines inyectoras, to quantity of errors been due to fluctuations in the pressesure of air, warming of oil, fact that derives in demoras, rejections or problems of quality. The utilisation of RoboCylinder and MPC reduce enormously the percentage of rejections or failures, helping of this form to a better efficiency and performance of the process. When speaking of systems of positioning multipunto and with repetitividades until 0,01 mm, or even upper, will comprise that so much the times of the processes like the cycles of change of format can carry to optimum levels.

A last parameter to take into account is the one of the useful life of the different devices and his maintenance. The estimate of life of a pneumatics cylinder of a lower route to 100 mm is of 25 million cycles, or 10.000 km for cylinders of upper career to the 100 mm. The useful life of the actuators MPC surpasses the 500 million cycles. A pneumatics solution executing 1 cycle by second would not bear a year, in front of the 15-20 years of hope of operation of the actuator MPC.

All the Robocylinders of IAI have like standard of AQ seal, that consists in a band of resin impregnated of lubricante solidified. This innovative technology of lubricación ensures one no need of maintenance during 5.000 km of trip or 3 years.

Automation of machines inyectoras

The extensiva automation of the process of injection, is not an impossible, is more, is an enormous value added for those who achieve to do it to rational prices. The diversity of the production of a determinate company, the different demand of distinct models/piece, and a fast adaptation of a model to another, requires of a solution: automation.

Automation yes, but rational, with an interface graphic easily intelligible by the operarios of the automatic lines, with an appropriate gestión of recipes and orders, and with an efficient communication to the office of production that manages the needs of the production in real time.

The interface of user, interface man-machine, or more commonly known by his initials in English HMI (Human-Machine Interface), is all a group of components, so much of hardware as of software, that allow to the operario communicate and interactuar with the control of a machine or line of process.

The main requests of the industrial interfaces always have been, and owe to follow being it, so much the operating capacity like the robustness and stability of behaviour. The environingingmental conditions in which they find these systems in the plants of the alimentary or pharmaceutical industries between others, are not the ideal and can find us with situations no wished, but unavoidable, like extreme temperatures, humidity… to which has to to be prepared the interface.

In base to the importance of the communications, already was with the operario or with the distinct departments, in Larraioz have developed systems HMI mixed, thought specifically to enrich the 'dialogue' with the operario.

These systems of modular conception integrate a tactile screen of 7”, 10”, 15” or upper, in addition to pulsantería luminous of type capacitivo, everything in a same frontal without recess neither salient. The options of screen of HMI cover the different formats 4:3 and 16:9, allowing the efficient utilisation of the multimedia tools such like reproduction of videos, representation of PDFs, communication of MMS, … The retro lighting of the screens realises by means of technology LED, what awards an upper shine, minimising the problems of fault of clarity (usual problem in the traditional screens when ageing the lamp).

The use of the pulsadores luminous allows that the handle more frequent or prioritario of the process-machine, do by means of these, deleting the need of reiterated pulsaciones in the screen and increasing besides the life of the same.

Each pulsador incorporates an external luminous band in yellow, green, red or blue, that can rotar to right or to left, fast or slow, put fast or slow turn signal, indicate steerings, remain lit, etc…These possibilities of visualisation, are enormously informative for the operario and reduce notably the risks of error of operation, when associating luminous states to functions or dysfunctions of the machine.

The devices HMI of Larraioz can incorporate, optionally, readers RFID, for a fast and safe identification of the operario and games.

The forms and methodology to the hour to assign images and associate symbols to states, do that an application was easily intelligible and intuitive for the operario of line or machine. Added to this, the possibility to visualise videos of help or assistance in screen, award to the programmer–integrador, the possibilities to do an amicable system.

Surroundings SCADA like Genesis32TM, Genesis64TM and BisVizTM allow to design spectacular graphic applications and of gestión of production with an optimum time of development. Tools like GraphWorXTM, TrendWorXTM, AlarmWorXTM, WebHMITM or MMX, entirely modular, give place to graphic applications so diverse like the ones of a simple machine, a complete line of production or a global process of production, packaging, storage and logistical of a company or group of companies.

With the convergence of processors of 64 bits, multi-cores and multi-processors, the introduction of the new operating systems Microsoft of 64 bits, and the demand of native applications that take advantage of said resources, Iconics enters Genesis64, the new generation of visualisation HMI/Scada. The Suite of Genesis64 includes different solutions that allow the connectivity of the plant of production and installations to the system of corporate business. Designed to squeeze the advantages of connectivity OPC UA, code managed sobre.net and technology SharePoint, allows to the operators of plant and to the professionals of IT integrate the concept of “business and production in real time”.

The new GraphWorX64 caters the platform for visualisation, taking the maximum advantage on exquisite representations in 2D and 3D in applications HMI and Scada. The user can build scalable charts based in vectors XAML that do not lose detail when it executes a zoom. Likewise Genesis64 taking also advantage on the appearance of transparencies of Aero, or integration of other tools and applications like Microsoft Office. The ideal colophon supposes the support of interaction multitáctil with the screen, what allows to the operario relate with the application by means of commandos Gesture to sail of total form on her, expand or reduce an area of visualisation, rotar and change seen, displace, …

As I complement ideal to the visualisation of Scada for operating systems MS Windows, Larraioz offers, like tool of connectivity, the commercialisation and technical service of Kepware.

Kepware, United States, is world-wide leader in software of communication for automation, and offers an only experience in OPC and connectivity of devices Embedded. Kepware Centres in the development of drivers of communication for controllers of automation, points of entrance/gone out and peripheral devices of field, for the operating systems of MS Windows such as Microsoft Windows Desktop (Windows XP and Windows 7), Server and Embedded (Windows CE, Windows XP Embedded or Windows Embedded Standard 7).

Kepware Is member of the foundation OPC (OLE for Process Control), the most known and widespread standard of industrial communication, allowing the exchange of data between devices of different manufacturers and the applications of control, without any type of proprietary restriction. The servers OPC allow to communicate the information between distinct PLCs, devices RT of field, the stations of HMI and Scada, and the applications of software installed in the computers of control of process. Still and when the Hardware and Software come from of different manufacturers, the fulfillment of OPC ensures the feasibility of a continuous communication and in real time. For devices that do not have of support of connectivity OPC, the server of protocol Or-WITH allows the fast and simple development typical of drivers of communication for almost all device with bus series or Ethernet, such as scanners of codes of bar, readers of RF, cells of load, sensors, and all an enormous range of industrial controllers.

The tool KEPServerEX offers now the new Server OPC UA, together with the option of driver Customer OPC UA. With support for more than 140 different drivers and protocols of communication, the connectivity OPC UA caters a robust and safe solution of Tunneling to avoid the applications distributed on DCOM and enable the concept of 'B2B for automation'.

Larraioz Offers like addition, products embebidos of Genesis and Kepware in his controllers MIPC, already installed, and of prices highly competitive, that fulfil the widest requirements of connectivity and visualisation required by the majority of the productive sectors and of processed of plastic matters in the alimentary sector, chemist, chemist, industrial, etc…

“More than 20 years in automation of machines and processes”

In the proposal of Larraioz Electronic Industrial mix more than 20 years of hard work to the service of the industry, investigating constantly new products and markets, developing solutions to resolve of efficient form the most complex works of automation.

And when we speak of “Solutions” include all the sense of the word: product of big provision and quality, wide knowledge and support on the same, fast logistics and permanent stock, competitive prices and, what is more important, an enormous human capital able to give solution to the most complex needs of automation.