Electrorecycling, pioneros en el reciclaje de monitores y televisores con tubos de rayos catódicos

24 de mayo de 2010

“Por la presencia de elementos contaminantes, la escasez de recursos, el coste de producción que representa la extracción de metales y muchas razones más, es necesaria la recogida y tratamiento específico de los residuos RAAE”. En opinión de Ramón Altadill, director comercial de Electrorecycling, estos serían los principales motivos que justifican el traslado, tratamiento y valorización de aparatos eléctricos y electrónicos obsoletos o fuera de uso. Una gestión en la que la ciudadanía ejerce un papel clave: “Es fácil concienciarse –continúa Altadill– sobre la necesidad de reciclar aquellos equipos voluminosos, pero no sucede lo mismo con los pequeños electrodomésticos, teléfonos móviles o juguetes de menor tamaño, susceptibles de acabar depositados en lugares no adecuados para su recuperación”. Y es que el volumen de desechos procedentes de los RAAE crece a un ritmo tres veces superior al resto de residuos urbanos. En consecuencia, cada vez ocupan más espacio en los vertederos que tienen una vida limitada. De no separar y tratar correctamente los componentes de estos aparatos, se dificulta el funcionamiento de las plantas incineradoras. Con el inicio del apagón analógico y la irrupción forzosa de la TDT, se prevé un aumento en el reciclaje de monitores y televisores con tubos de rayos catódicos. Vamos, los de toda la vida. “Entre el incremento ya experimentado durante el año 2009 y el que tendrá lugar a lo largo de este ejercicio, nos estamos moviendo en un aumento del 30% en el número de televisores respecto al 2008”, reconoce Altadill.

Primera empresa en Catalunya que trata y valoriza monitores y televisores con tubos de rayos catódicos, según RD 208/2005

El proyecto Electrorecycling surgió en el año 2001, a raíz de un concurso público de la Agencia de Residuos de Cataluña. En aquel momento, existían empresas como Ferro Vallès que reciclaban residuos RAAE de aparatos de la línea blanca. Sin embargo, no había ninguna compañía con la maquinaria necesaria para la separación, identificación, tratamiento y recuperación de materiales de monitores y televisores con tubos de rayos catódicos. “El motivo era la búsqueda de la mejor solución en cuanto a planta de valorización para los aparatos eléctricos y electrónicos, ya que en la misma localidad, seis años antes se había inaugurado una instalación para tratar frigoríficos y aparatos similares. Y en el año 1997, una planta para gestionar lámparas y pilas”, argumenta el director comercial de Electrorecycling, quien se incorporó en el año 2002 para organizar la recogida de material y supervisar la construcción de la planta en El Pont de Vilomara i Rocafort, en la comarca del Bages (Barcelona). “Esto último se llevó a cabo con la colaboración de Indumetal Recycling, como 'partner' tecnológico y Pilagest, participada por Senda Ambiental y Fomento de Construcciones y Contratas, responsables del seguimiento de las obras. La recogida de los residuos se inició con empresas vinculadas a este ámbito, a partir de enero del año 2002, momento en el que Electrorecycling comienza su actividad”, apunta. Mientras se ultimaban las obras de la planta en Cataluña, los desechos se enviaban a Indumetal Recycling donde se trataron hasta finales del año 2003 cuando se inauguró la instalación en la localidad catalana. “A lo largo del año 2002, ya se reciclaron 1.300 toneladas de RAEEs”, matiza Altadill.

La empresa recogió 14.000 toneladas de RAEEs, en el año 2009

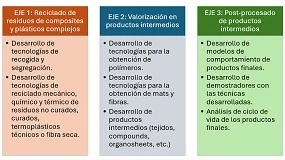

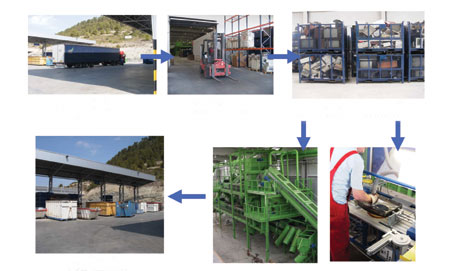

Durante el periodo 2004-2009, Electrorecycling pasó de tratar y valorizar 4.000 toneladas de residuos RAEEs a 14.000 toneladas. “En un principio, y tras la inauguración de la planta, trabajaban una veintena de empleados en un solo turno. Actualmente, la instalación crea una cincuentena de puestos de trabajo aunque en estos momentos, se valora la implantación de más personal en un tercer turno, en función de la mayor recepción de monitores y televisores analógicos”, puntualiza Altadill. Por tipología de negocio, el 70% de la totalidad de los RAEEs que recibe Electrorecycling proceden de los puntos de recogida, es decir, del ámbito doméstico. El resto, son de origen industrial. El ámbito de actuación se limita a Cataluña, Andorra e Islas Baleares, mientras que el resto del país lo cubren empresas como Indumetal Recycling, con plantas de tratamiento en los municipios de Asua (Vizcaya) y San Agustín de Guadalix (Madrid), Empresa de Gestión Ambiental SA (Egmasa), sociedad pública de la Junta de Andalucía, entre otras. Una vez recibidos los aparatos reciclados, el sistema comienza con la separación manual de aquellos componentes fáciles de identificar. “Entonces se clasifican los equipos en dos procesos distintos, en función de si se trata de televisores y monitores u otros equipos. En el primer caso, separamos los dos tipos de vidrio, aspiramos el fósforo de su interior, identificamos la parte electrónica que añadiremos al otro proceso, así como bobinados y cableados ya separados. En el segundo caso, se fragmentan los aparatos de forma que los condensadores y las pilas se separan sin trituración para su posterior envío a la planta adecuada. Por su parte, los metales se separan y gestionan, al igual que las tarjetas electrónicas”, detalla gráficamente Altadill.

Una 'nueva vida' para el plomo de televisores y monitores, en forma de cerámicas

Una vez apartados del resto de RAEEs, los monitores y televisores se colocan en la base de un tobogán provisto de una cinta transportadora que los dirige a las mesas de selección donde se separa la carcasa del monitor. La carcasa de plástico se selecciona según su composición y calidad (de poliestireno o plástico negro, de alto impacto, conocido también como PS, plástico ABS, el de los monitores) y posteriormente, se tritura. Si el televisor es muy antiguo, puede ser que la carcasa sea de madera. Después se procede a separar los diferentes componentes electrónicos: tarjeta de circuito impreso, rosetas, bobinado, etc. El siguiente paso, se centra en el tubo de rayos catódicos, que contiene plomo y polvo de fósforo, dos de los elementos más dañinos para el medio ambiente. El primero, concentrado en el vidrio del cono y el segundo, impregnando el vidrio de la pantalla. Con un disco diamantado se resigue el contorno del tubo y mediante unas cintas incandescentes se quema hasta que por estrés térmico se provoca una rotura. A partir de ahí se separa el vidrio del cono, menos grueso que el de la pantalla. Este último, debido a su menor contenido en plomo, se puede utilizar para cualquier aplicación posterior. Sin embargo, el vidrio del cono es muy rico en plomo, por lo que se vitrificará y se le dará un nuevo uso en la construcción de cerámicas y esmaltes. La textura es más rugosa que la de la cerámica normal, aunque mucho más resistente a posibles rayadas.

Las fracciones de los RAEEs se envían a gestores autorizados

Cuando estos equipos han sido desmontados, se producen las diferentes fracciones, en función del tipo de material. Existe una primera criba que da lugar a la primera separación granulométrica. La más fina pasa por un separador magnético que aparta la fracción férrica de la no férrica. La más granulosa circula por otro itinerario donde se halla otro separador magnético que realiza una función similar a la primera. En definitiva, cada fracción ha de quedar limpia, libre de impropios. De lo contrario se ha de reprocesar. Finalmente, los operarios apartan manualmente todas las fracciones resultantes: transformadores, aluminio, cobre, cables, tarjetas de circuito impreso, madera, acero inoxidable, latón, condensadores y pilas. Todas ellas se harán llegar a gestores externos autorizados por la Agencia de Residuos de Catalunya.