Interview to Eva María of Gala Antolín, attaches to steering of Cetece and Rosa González Leyba, of the department of extrusion of Aimplas

The last years, like alternative to the plastic manufactured from oil, proliferate new solutions like the plastics elaborated from renewable sources like the corn, the already popular acid polilático (PLA). However, two technology centres Spaniards –the Valencian Aimplas and Cetece, of Palencia– have stepped further and find immersed in a European project LIFE+, designated BREAD4PLA, that will allow to obtain innovative biodegradable containers from by-products of the industry of the bakery and bollería, allocated again to pack products of this sector. Eva Mª of Gala Antolín, attaches to steering of

During the past edition of Equiplast presented the project BREAD4PLA, in what consists?

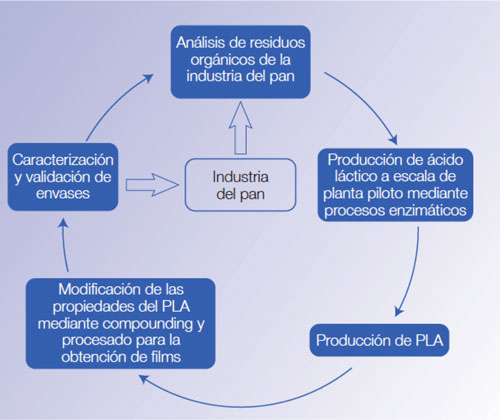

BREAD4PLA is a European project LIFE+. With his development pretends show to European level the feasibility of an innovative solution and medioambientalmente sustainable promoting the recolección of by-products of the sector agroalimentario, in concrete, the industry of the bread. The consortium of the project is expert in five key points for an innovative system of waste treatment, that will drive to the manufacture of new containers for products of bakery and bollería, closing like this the cycle of life: the waste treatment of the industry baker, the production of acid láctico (To THE) to scale of pilot plant by enzymatic roads, the production of acid poliláctico (PLA), the modification of the properties of the PLA by means of compounding and his processed for the obtaining of films, and finally, the validation of the new containers for products of bakery and bollería.

Splits of the team of investigation of the four centres that participate in the project.

Which are his main aims?

The main aim of BREAD4PLA is to show, in a continuous process to scale of pilot plant, the feasibility of the synthesis of acid poliláctico (PLA) from products of waste of the industry of the bread and his utilisation in the manufacture of a film 100% biodegradable for his employment in the packaging of products of bakery and bollería, closing like this the cycle of life.

Other specific aims are:

- Increase the value of the waste of the industry of the bread by means of his recovery for the production of acid láctico.

- Show the technical feasibility of a process pre-industrial of acid láctico from waste of the industry of the bread.

- Scalar the process of polymerisation of PLA using sour láctico obtained from the fermentation of waste of the industry of the bread.

- The obtaining of a film thermoplastic 100% biodegradable of PLA from waste of the industry of the bread and that contain 95% of renewable sources.

- Replace the human foods like prime matter to produce PLA by products of waste, reducing like this the problems related with the fluctuations in the prices of the foods.

Which is the process, that is to say, since they collect the waste of bread and bollería until it turns into a container?

The following graphic describes the process:

Will have industrial application? What will allow to the companies manufacturers of containers?

Yes, expects that it have industrial application. That is the aim of the project, show the technical feasibility, economic and environingingmental of the up described process. It is necessary to take into account that the partners participants have the necessary installations to carry out this escalado to level plants pilot.

Specifically the manufacturers of containers will benefit of the advantages and value added that the biodegradable material-PLA from waste of the industry of the bread will provide.

Which advantages and value added will obtain of his set up?

Nevertheless, no only will see benefited the companies manufacturers of containers for the industry of the bollería and bread, but also there are other companies/sectors to which directs the project and that they can see increased his volume of business with the industrialisation of this process, like producers of To THE or companies of waste management, or even the chains of supermarkets that already at present bet by products of environingingmental sustainability.

They think that it will be viable economically or does fault long so that pass of phase of laboratory to industrial phase?

The PLA is a commercial material that at present has a reasonable price in the market of the biodegradable materials. The obtaining of a material with similar characteristics from waste of the industry of the bread would allow to reduce the costs of production of the same. As it has indicated previously, the project pretends to show the feasibility of the process to scale of pilot plant, and for this, the proofs that will realise in the different phases (essentially production of To THE, obtaining of PLA, manufacture of the film and back packaging), will have equipment of character ‘plants pilot', no of laboratory. True is that, later, will need an optimisation of the process to give the definite jump of this demonstration pre-industrial to the whole industrial process, and that besides will have to develop the system to logistical level, of transport, etc. to ensure an optimum operation of the complete process.

The resultant material, the PLA… which strong and feeble points will have?

Would treat of containers with greater environingingmental advantages that the manufactured at present with the PLA pertinent of renewable sources, since in addition to being biodegradable, would proceed of a residue to the that besides would be him giving an exit to the market, providing him an economic value.

The project contemplates a stage of modulation of the properties of the PLA for his correct processed by the different technologies of obtaining of films by extrusion, as well as to obtain the properties required in applications of containers of bread and products of bollería. If the material obtained can process for the obtaining of films of different thicknesses, said films could employ to pack other types of foods.

Like problem could mention the logistics that will be necessary to develop for the management of the by-products to employ. However, it is necessary to consider that the EU supports this type of performances, and on the other hand, that the project contemplates a high number of activities of diffusion to give to know the project in Europe in the different sectors involved, and facilitate a back collaboration between companies through other projects to realise the escalado industrial and to organise all the logistics.

The PLA resultant could also allocate to other applications as for example, articles of menaje desechables, like dishes, glasses, bols.

It is only for the sector of the feeding or can do extensible to other areas of application?

Once obtained the film or the plate, these could employ equally in other applications whenever they fulfil with the necessary requests in each case, by what it would be necessary to study his feasibility for each concrete case. An example would be the articles of menaje desechables, like dishes, glasses, stock exchanges, etc. In the project will study the feasibility for containers of bread and products of bollería, where the requests regarding resistance to high temperatures of the material, chemical resistance or of barrier to gases are not of the highest.

The sustainability is a fashion passenger or is a tendency on a long-term basis…

The sustainability is a need. The centres that participate in the project are conscious that any development of material, process, product, etc., has to do considering the environingingmental factor, in addition to the technician and the economic.

Is very important to investigate to obtain environingingmental improvements that afterwards can do reality in the company, as only like this will reflect in the market and will achieve a true result in the environingingment.

Himself Is truth that in the last times is hearing more on the importance of the sustainability but expects that it was not something isolated or fashionable but this interest keep growing and incorporate in the day in day out of the companies.

In fact, from Europe is improving the development and fulfillment of environingingmental politics, in which the European projects have to contribute. BREAD4PLA will help to improve the environingingmental appearances, by means of the decrease of waste, promotion of the production of biopolymers, and the minimisation of the environingingmental impact of the products of final container of the industry of bollería.

Speak us of the project, when initiates and when foresees that it finish...

The project initiated in October of 2011 with a term of execution of 36 months, by what will finalise in September of 2014.

Who is involved in the project?

BREAD4PLA gathers 4 skilled partners in the different sectors involved. Aimplas (Association of plastic Materials, situated in Paterna, Valencia), coordinator; ATB (Institute of Agriculture of Germany), Biocomposites Centre of the University of Bangor (England) and Cetece (Technological Centre of Cereals, situated in Palencia).

Through a team of diverse work, formed by engineers agronomists, chemists, experts in biotechnology, biorefinería and escalado of bioprocesos, gather different capacities to ensure the success of the project.

Besides, BREAD4PLA has the participation of companies interested in collaborating externamente in the project. For example, in Spain Panrico, Group Siro, of some way involved in some stages of the process, as it is the supply of different waste of the industry of the bread for the production of acid láctico or the supply of products of bakery and bollería for the validation of the new containers.

Nevertheless, expects involucrar to a lot of more companies/entities in this interesting project, via the Forum that will find in the main page of the web: bread4pla-life.eu, that will be active in February 2012.

In what other projects finds immersed the Cetece-Technological Centre of Cereals (Spain)?

In the national field, are finalising a project consorciado with other five centres of investigation; ITC, AIICA, Cidetec, ICV CSIC, and ITM. The project is funded by the Ministry of Science and Innovation and under the acronym Fotocer, has like main aim the development of coatings fotocatalíticos that give place to surfaces with properties bactericidas and autolimpiables, by means of processes that provide an effect fotocatalítico effective and durable, at the same time that they are susceptible to be escalados to industrial level.

Inside the Department of R&D, carry out projects of investigation and of development of products for companies, fundamentally, of the sectors of transformation of cereals, under contract of confidentiality.

The main lines are:

- Design of formulas for the obtaining of healthy products from functional components already existent (sour grasos, fitosteroles, polifenoles, dietary fibres, etc)

- Characterisation of foods and by-products for the obtaining of natural extracts from the by-products and to the application of the components obtained to the development of new foods.

- Application and optimisation of bioprocesos for the obtaining of new foods or alimentary ingredients.

‘Analyses of flour'

The Laboratory of the Cetece, is specialised in the Control of the Quality of Wheats and Flours, has the most innovative technology in the control of microbiological analyses, physical-chemical and reológicos of flours. It does a year purchased a Farinógrafo AT of Brabender, only in Spain, that allows us measure the consistency of the mass during the process of kneaded.

Cetece Coordinates annually the organisation of a circuit of intercomparación of alveógrafos where, from the statistical study of the results of the distinct participants, elaborates and distributes a final report to the participants.