"We believe in sustainable growth in the plastics industry, but we have caution to exaggerated optimism"

I'm talking about trends that are not a small "distraction" of every day in our business. I refer to global mega trends that will change our society, industries and economies in the long term and that will also lead new technologies. Such trends are not an addition to our every day business; in fact, they will shape the future.

They are exactly such trends and visions that will be a common thread of our time, if they may Mint by the financial and economic or assumed crisis as stable.

This is a common issue with which we, the German Federation of the industry of the plastic, we also deal in our activities. In the K we tejeremos this thread to a close and stable network of new developments and trends. By doing so, clearly we aim to demonstrate a sustainable perspective for and by the plastics industry. This is the common thread that I like to 'spin' with you today to realize the slogan of the 'Plastics' plastics industry - the material of the 21st century.

The special presentation of this year in the K, will also, these much more tangible perspective. Based on ' Visions in Polymers' will reveal the future of our materials:

-How is our daily life in 20 years?

-What contribution can make plastics for the essential human problems?

-What potential applications that still today are future will be introduced in two decades?

The presentation will continue to be a dual approach: on the one hand, to clusters of particular themes will use electronic media in an innovative way. On the other hand, will be organized around panel discussions daily with first level experts in the field of science and research, OEMS and the plastics industry. Special consideration will have the energy and energy efficiency aspects.

Let me spend a little more time to the immense potential of plastics in terms of safeguarding the natural sources, energy efficiency and the protection of the climate, increasingly recognized potential for the public and politicians, also.

Plastics are the material to choose when there is the challenge of energy efficiency. Plastics, in its multifaceted application aspects, allow many energy saving compared to the amount of energy required for their production and transformation. And indeed, as we will see in the K, new technologies and processes continue paving the way for even greater savings in the manufacturing and processing of plastic.

The most important tractors from the use of plastic in the variety of applications are its ease of processing, properties which allow to manufacture the measure and its low density with results of lightweight applications. In this context, the plastics industry and their innovative applications serve as enabler and solution critical to provide many other industries in regard to climate protection. I am confident that this potential will be much more tangible through many examples in the K.

What are the key trends and developments to medium and long term that they highlight and will present manufacturers of plastic, transformers and machine manufacturers of plastic and rubber in the K?

- Additives to nanoscale particles to improve fluency and enhance the mechanical properties of plastics;

- Types of plastic, allowing the resistance to distortion by heat for applications in electrical engineering and lighting

- Types of plastics with improved transparency, increased refraction and improved optical properties

- New types of technical plastics and materas renewable materials-based standards

- New biodegradable types of plastic

- New extensions in Wood Plastic Composites (WPC)

In what refers to machinery, tools and equipment:

- A better use of the machinery by shorter production times, greater flexibility and minor times of change.

- Shorter cycle times, cost of lower units and higher productivity through fast machine movements, optimization tools, a more efficient cooling and a synchronized management equipment.

- Concepts for efficient control of temperature of the mold, allowing a configuration more economical processes, improve the quality of the product and reduce energy consumption

- Integrated monitoring of product quality, elimination of defective parts in line and documentation of the process and quality data.

- Increased use of sustainable electric motors on machines of transformation to reduce consumption and energy costs

- Combination of a wide variety of methods of injection such as the processing of foams in a single course to integrate a wide variety of functions in a plastic component.

I am sure that we can expect many new developments for all the points mentioned above and many other aspects. I would also like to highlight a new instrument of the organizers of the K, which we have called 'innovation compass'. The Advisory Board of exhibitors and the newly created Scientific Council of the K 2010 has been developed jointly by Messe Düsseldorf. 'innovation compass' will present the main aspects of the K in the area of raw and auxiliary materials, as well as in the area of machinery and equipment. These themes are areas of potential innovations that provide improvements or basic changes and hence true competitive advantages. Six weeks before the opening of the K, the 'Innovation Compass' can learn online on the web: www.k-online.de.

However, many innovations that we still regard as "great" will not take place as great discoveries or inventions of new polymers.

In the long term, our innovative strength is not simply based on our ability to invent or on our health of ideas and the ability to put things into practice. Rather, this is one of the greatest challenges these days to identify long-term innovative trends that will impact our industries and our customer industries. We need to convert the resulting requirements in practical contributions.

And while there are countless trends and developments, just have a few mega real trends. However, all of them form a dense network woven between them - as a complex network of routes or sections, as shown in the picture/chart.

Not all these pathways are relevant to our industry in the long term. Therefore, we need to be accurate in identifying our areas of action in such a way that we do not miss the boat when the solutions.

So, What are the fields of action relevant to the industry of plastic?

Many of these developments can be grouped into mega trends:

- A growing population and demographic changes

- Globalization and urbanization

- Protection of the climate and energy

- Revolution Health

- Acceleration of technological change

These mega trends have in common, our ability to respond to them with sustainable solutions by polymeric materials, all of which are aimed at making our world a more ecological and economical and improve the quality of life for a greater share of the world's population.

I'll show you a few examples. Prosper diodes electroluminiscentes that offer the combination of a high brightness and low energy consumption. Temperature-resistant and conductive heat plastics have been developed to allow be shaped freely and produce economically.

Or think of the plastic of reinforced carbon fiber. They allow to produce components with an extreme resistance to stress and a very light structure. The production of parts on a large scale possible soon, these are used from legs and artificial arms for amputations up pieces of car or the blades of wind turbine rotors.

This is the potential for plastics when we talk about 'material of the 21st century'. And it is in our hands to maximize this potential. How can we do? Let me give you a few examples from the area of 'construction and modern life'.

This is an aspect involved in diverses mega trends at the same time, among others, such as:

- A growing population and increased urbanization

- Or increasing demands aimed at constructive solutions more ecological and sustainable

- Rising standards of living in comfort, design and security requirements

Plastics are capable of providing vital solutions to all these requirements. A conclusive aspect for all claims in respect of the residential, commercial or industrial building is: how the construction industry can help protect the climate, especially when confronted with the fact that the buildings are currently responsible for the use of more than 40% of the world's energy and about 30% of the? global greenhouse gas emissions?

In addition, innovative concepts for the residential construction for example, should significantly increase the available living space while at the same time they should be sustainable. The atmosphere light and the light of day as well as a high degree of transparency have become a central issue while in parallel rooms should be clearly structured and allow maximum energy efficiency. Both to conserve the financial sources of the owner of the House and protect the natural sources at the same time. With regard to industrial and commercial buildings, architects and designers are also exploring new lands: 'Eco - commercial buildings' are the word of fashion for innovative offices or other commercial or industrial buildings, enabling concepts of sustainability and concepts of buildings that take advantage of innovative plastic technologies.

Security aspects have also grown in importance: new developments to improve the resistance of flame in healthy organic products, as well as special grades of high temperatures place result in applications for saving lives such as fire and smoke detectors.

Modern applications electro and electronic also make use of materials to be used under electrical currents or developments of continuous heat.

In general, our products are valid proven record in a wide range of areas for the construction sector, given its unique properties, including:

- Insulating panels for walls, ceilings and floors

- Sustainable LED for exterior and interior lighting

- Systems of floor coverings

- Sheets

- Photovoltaic elements in plastic frames

- Plastic pipes

- Sandwich panels with metal face and heart of plastic and

- Systems of sealing.

Solvent-free adhesives, raw materials coated anti corrosion or sustainable LED lighting systems are other products used in this sector. The use of plastics in architecture has ignited the imagination of architects, designers and engineers since 1960. Meanwhile, their areas of application go beyond "traditional" fields of thermal insulation or simple structures of roofs.

Polymeric materials offer new dimensions for geometries and designs. Large areas and multidimensional forms opens new horizons of creativity, as well as functional possibilities.

This aspect of growing functionality of plastic materials has also been well defined as one of the themes of the K 2010.

The trend towards functional plastics, parts and surfaces reflect the demand for additional properties not necessarily found in traditional plastics such as:

- Electrical and thermal conductivity

- Nonlinear optical properties

- Magnetic orientation and

- Ability to convert electrical energy into light and vice versa

In the surface area, the demands include:

- Ability to auto cleaning

- Anti-static properties

- Specific properties of accession and, if possible,

- Ability to enable or disable the properties.

For me, there are two very important things: on the one hand, our joint efforts to ensure a sustainable perspective in our industry. On the other hand, these days another hot topic that is definitely a cause for hope of sustainable perspectives, too, is the football!

Like me, hundreds of thousands of people in the stadiums and more millions from their televisions and large screens are still the World Cup games in South Africa these days. In this context, I am proud that our materials are part of the game!

It begins with the use of our materials for the construction of the sports stadiums or in the equipment and clothing of many players. And no we get tired of listening to it, on the ball. The official ball is made from a variety of plastics. To make this high-tech soccer called 'jabulani' ball, the manufacturer has worked closely with various manufacturers of plastic to find the best possible solution. There is hope in this success story: even our teams write the history of the sustainability and success, and I hope that our international guests forgive me that my wishes are directed to the best German team!

But no matter who takes home the trophy at the end of the day, one sure thing: be part of this game. And plastics are the material of the champions.

Let's take a moment to reflect the current state of the plastics industry. It has not only been a year in which we have experienced one of the worst financial and economic turbulence of the past 50 years. The recovery has begun, and it seems that in a sustainable manner, however, begins on a level very low.

The crisis has also caused many more obvious than before economic and socio-political problems, and no doubt aggravated many of them. The unemployment rate is at historical record and whole countries are facing bankruptcy. For many of our customers industries times have also been a challenge.

We need to go to what is essential to ensure a sustainable basis of investments to long loop of our private innovation activities. The first quarter of 2010 shows again that we are on the road to success: the plastics industry is and will be one of the key international industries.

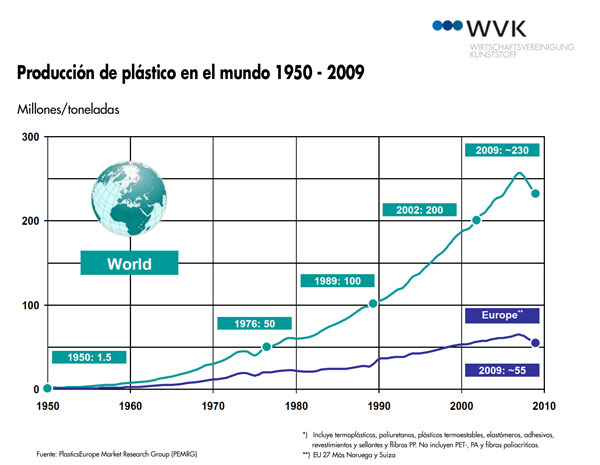

Looking back, have occurred in 2008 throughout the world nearly 245 million tons of plastic materials. Sixty years ago the global production was between one and a half million tonnes.

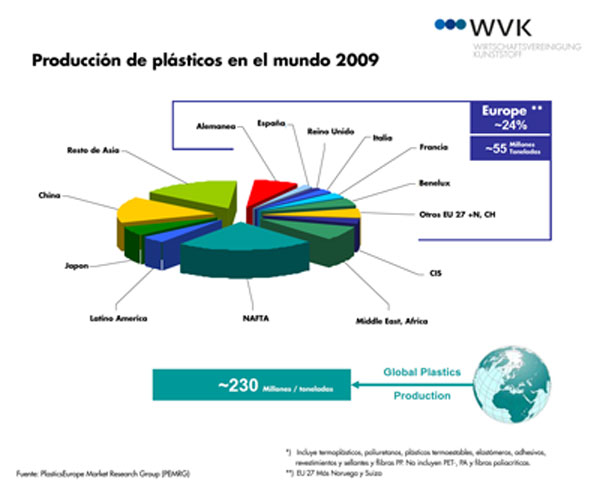

This development represents an average of annual growth of about 9%. Even in the year of crisis of 2009 international plastics production was about 230 million tonnes. About 55 million tonnes of international production of plastics in 2009 are attributed to Europe, with Germany as location predominant with 17 million tonnes.

Sales of manufacturers of plastic in 2009 dropped 22,800 million euros to 17.5 billion euros, a 23.2% less. The decline in production was 15% of 20 to 17 million tonnes. Plastics prices declined in the last year also. The price of plastics index shows a decline of 5.8 per cent. The volatility of the price of oil under additional strain. As a result, the margins for the manufacturers of plastic remained under severe pressure in 2009. The first two quarters of 2010, have been very encouraging for manufacturers of plastic and better than expected.

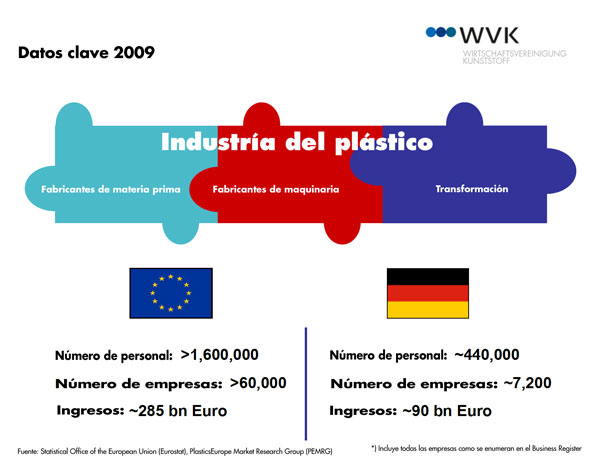

However, these figures have yet to socio-economic: throughout Europe, manufacturers of plastic, transformers and machine manufacturers, together employed 1.6 million professionals in more than 60,000 companies, generating a total of 285 billion euros revenue in 2009. This is a respectable considering the massive losses that other sectors have experienced during the crisis period. This shows that despite the crisis in the plastics industry is and will be an economic factor of increasing importance. The level of employment in our industry remains high and relatively stable in Germany, and the businesses in 2010 began much more encouraging than many companies expected.

Noting the sector of manufacturers of machinery for plastic and rubber, this year 2009 it has been deeply affected by the reduction of working hours.

For most companies only part-time work can prevent the reduction of its workforce in the long term. However, there have been companies in this segment where permanent reduction of staff they could not avoid. The plastic processing industry has also had to register a decline of the their templates in 2009. On average, however, transformers managed to retain qualified staff. This again emphasizes the attractiveness of our industry.

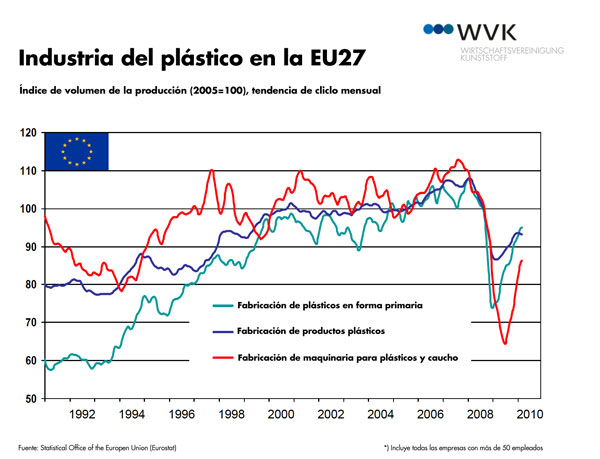

In terms of the volume of the production index for the manufacturing areas of plastics, processing and manufacture of machinery during the course of the last two decades, the severity of the decline of the economy becomes especially obvious. However, it clearly reveals a last recovery recorded during the last few months.

The recovery becomes even more evident in the first quarter of our industry in 2010, with the figures for 2009.

All sectors of our industry recorded significant levels of double-digit losses in the year 2009. The transformation of plastics industry still has to face major losses. For the first quarter of 2010 this panorama has changed and all segments show a positive development of production.

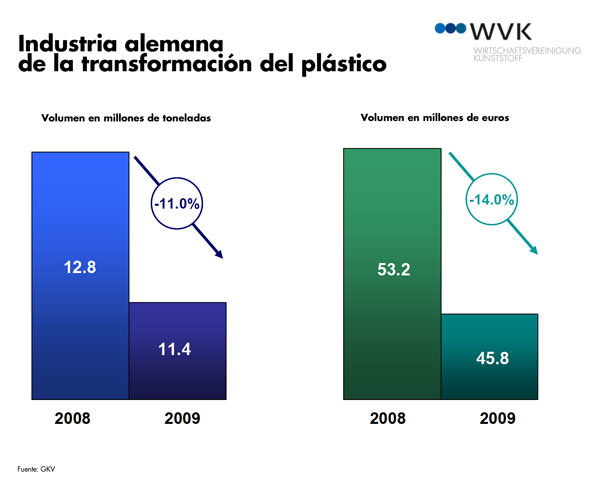

Carefully observing the transformation of plastics in Germany industry, in 2009 this sector generated 11.4 million tonnes of product in terms of volume, recording EUR 45.8 billion in value. Compared with the previous year, it's a drop in value of about 14 per cent.

The packaging industry still represents the largest subsegmento in the sector. However, it was also a decline in the sales of roughly 10 per cent or EUR 12.5 million. This was mainly for the fact that the industrial segment of the packaging had to contend with significant losses. In contrast, the business of the packaging of consumer goods remained relatively stable.

Suppliers of technical plastics for the automotive and electronics industries were severely affected by the crisis. They generated only 9,600 million euros in total in 2009, a decrease of 20% of sales.

Suppliers of plastic for the construction in Germany industry had benefits due to the economic measures of promotion. In the first months of 2010, the transformers of plastic have experienced an increased demand steadily in all areas.

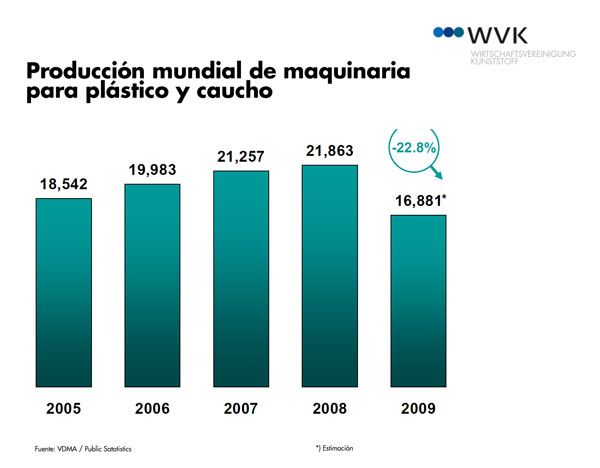

Reference to the State of machinery for plastic and rubber manufacturers shows that the average production of plastics has undergone a massive decline last year.

Based on data estimates and official, global production fell by around 17 billion euros, a decrease of 22.8%. The German share of equipment and machinery for plastic and rubber dropped from 25.3% to 22.6%.

In Germany, the volume of production in key areas for this sector concluded with a value of 3.8 billion euros based on official data. This is a decrease of 31.3 per cent compared with the previous year. German exports of plastics and rubber machinery fell in 2009 near a 33.9%. According to German Federal Statistical Office, this results in an export value of 2.6 billion euros, while 2008 remained a figure of about 4 billion euros in export value. Imports of machinery manufacturers for plastic and rubber to German transformers on 2009 fell 36.7%, to a total 539 million euros.

For the first time, the plastic and rubber Manufacturers Association has published a scientific estimate for development in the medium term in this sector. On the basis of this forecast, expected an increase in sales of about 11 per cent in the coming year. German machine of plastic and rubber manufacturers see this estimate with great relief. However, the industry starts of relatively low growth, that an increase of 11% leaving them close to a quarter below 2008 levels.

Developments of the first quarter and the next few months make us rely on a positive development in 2010, in Germany, Europe and around the world. However, you will have to see if this trend continues the rest of the year. Only then we can say: the crisis is over. We believe in sustainable growth in the plastics industry, but we have caution to exaggerated optimism.

By way of conclusion, in relation to future trends in our industry, the potential for innovation of our products will be a decisive factor and is in our hands raise that potential to its maximum degree. We work as one team: plastic manufacturers, transformers and machines for plastics and rubber manufacturers, led by truly sustainable solutions to our customers and consumers.

I am sure that we as an industry we realized the change. And we have already initiated important developments for the future. You need now is discipline and vision to lead our efforts in innovation to a clear balance of sustainability and profitability. By doing so, we will be able to meet our objectives of bringing sustainability to the industrial value chain.

Thus, we will conduct innovative solutions aimed at the requirements of our customers and will contribute to the social challenges of active energy efficiency and climate protection. Future generations may take advantage of the solutions that we develop today.

This potential is that makes the plastic material of the 21st century.