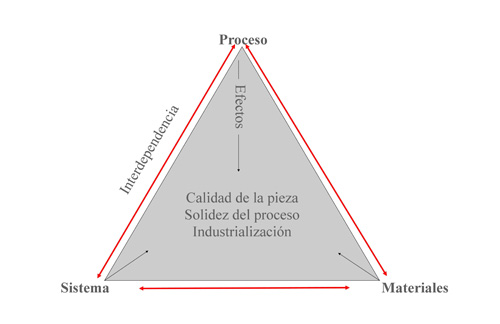

“Look for a triangular balance, equidistant and interdependent between the system, the process and the materials”

Interview to Víctor Paluzíe, director of RMS Rapid Manufacturing Systems

Víctor Paluzíe is director of

Víctor Paluzíe, director of RMS, distributors of EOS GmbH, beside the team EOS M 400.

With what different technical of manufacture and prototyping fast explains the market in the actuality?

Inside the additive manufacture we are used to to distinguish between the technologies of direct manufacture (rapid tooling, rapid manufacturing) and the technologies of prototyping fast. Between these last find basically the ones of FDM (fused deposition modelling), that are the base of the majority of printers 3D that have arisen lately in the domestic market; material jetting (inyectoras of light-sensitive resin); binder jetting (injection of of agglutinative on material); estereolitografía, and LOM (laminated object manufacturing), that use pieces of paper to create objects 3D, between others.

And regarding the technologies of direct manufacture?

Exist those that designate of powder bed fusion (PBF), according to the American Society for Testing and Materials (ASTM), where a source of thermal sensors power melts of selective form sections of a mulch of dust, on polymers or metals, to produce final pieces of direct form. The process in metal is also known like sinterizado selective by laser (SLS), sinterizado direct on metal (direct metal laser sintering -DMLS), or selective fusion by laser (selective laser melting -SLM). Also they are used for the development of product by means of the production of functional prototypes.

Speak us of his advantages.

In the first place, the freedom of design. The additive manufacturing (AM) allows to produce an object of practically any form, even those that today are not susceptible to manufacture by means of conventional technicians. Another advantage is that it can increase the complexity of the object without that thus they increase the costs of manufacture. In the case of rapid tooling, can produce insertos with internal channels for control of the temperature during the cycle of injection.

What other advantages would stand out?

Allow to delete the mould, that is to say, produce directly, and, therefore, delete time and costs of manufacture of tooling. Also it offers the possibility to realizar light designs, since the AM allows the reduction of weight through the topological optimisation (for example, with UGLY, finite element analysis), in addition to the integration of pieces, reducing the requirements of assembling by means of the consolidation of pieces in an alone component, even is possible complete assemblings with pieces with movement. And there is more.

Say me.

Delete phases of production —can produce complex objects of an alone time and in an alone step. Besides, the pieces produced by the technology of EOS have mechanical properties equal finals or in some upper cases to the pieces manufactured by conventional technologies (like smelting or mechanised).

These are the advantages, but which are his limitations to day of today?

In EOS prefer to speak rather of obstacles to surpass and challenges to reach and go advancing in the implantation of the technology of sinterizado laser in the most demanding industry. Thus, we look for a triangular balance, equidistant and interdependent between the system, the process and the materials (see diagram). This allows to increase the solidity of the process, the industrialisation (automation, control of quality, ease to operate and productivity) and the production of pieces of high susceptible quality to be certified in sectors of high value added like the aerospace, the doctor or the industry of high requests of quality.

What can do this technology by sectors like the dental?

From solutions for bridges and crowns or partial dentures until dental implants for a better osteointegración. With a system of EOS produce in the order of 450 dental crowns daily. Simultaneously to the creation of bridges and crowns and to check his adjust, the system EOS Formiga P110 for plastics advanced can manufacture in 14 hours around 40-70 dental models of high precision and quality with some very competitive costs.

The technology and his applications

aeronautical sector component manufacturing sector component manufacturing sector component manufacturing

In motors to reaction, inner and UAV. Design of high complexity built in an alone piece much lighter, integration of functions, substantial reduction of costs, substantial reduction of weight, of terms of delivery and engineering. Possibility of development of new materials for the sector.

Medical

Dental applications, devices ortopédicos and implants, surgical instruments and medical devices.

Automotive sector

Light components and complexes through the freedom of design, integrated functionality without tools of manufacture for the reduction of costs and pieces individualizadas that fulfil the needs and requests of the customer.

Industry

- Gripper: Light components and complexes through the freedom of design

- Machinery of special use: integrated functionality and without tools of manufacture, exchanger of heat.

Mould

Design more intelligent of the channels of refrigeration. It contributes saving of costs, reduction of the time of cycle, greater performance and reduction of the tax of rejections.

Lifestyle

Shod, web and gadgets, architectural modelling, design of interiors, fashion, accessories and jewellery.