Pedestrian protection of far-reaching

May 11, 2010

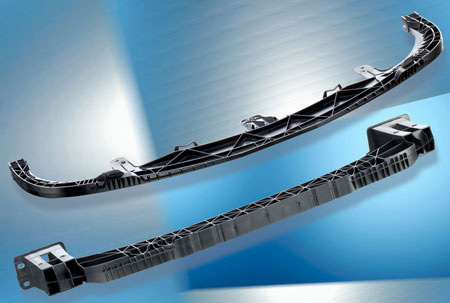

The LBS is a component designed to meet the latest regulations relating to the protection of pedestrians and requires the use of high performance materials. The polyamide has been optimized specifically for the antishocks applications and has already proven his capabilities in other different vehicle components.

The LBS of the Opel Corsa was innovative with regard to the protection of pedestrians that offered, and the Opel Insignia managed to improve on the basis of that experience, enabling the design of a particularly light and fine component that fit into the limited space available for installation.

Oft-tested simulation program

BASF has developed versions of the LBS by computer with the help of his patented Ultrasim simulation program. The continued expansion of the capabilities of the instrument has enabled the combination and automation of the information required on the local characteristics of a component using numerical optimization methods.

What once was first in the Opel Insignia, the so-called effect morphing or optimization of the form during design calculations, is now the standard technology included in the package of the program offered by BASF to these pieces. Thanks to the great improvement of the accuracy of the predictability, now can almost eliminate the costly and multiple construction of prototypes. Today, the design of demanding components of plastic would be almost impossible without computer programs like these.

PA to PP for the protection of pedestrians

When compared with the manufactured LBS with polypropylene (PP) modified for impact of other manufacturers of cars shows that the LBS of the Opel Insignia made of Ultramid B3WG6 CR is up to 50% lighter than the PP LBS (1 kg to 1.6 kg) and 50% more narrow at its widest point. Additional studies of both components have shown that the LBS of Opel presents a rigidity and a nearly three times higher energy absorption. Taking into account the cost of the equipment, an LBS made of Ultramid CR offers the end-user a weight saving of around 66% with the same cost and energy absorption. This is especially important when the available installation space is limited and weight requirements are especially demanding.