Minimize the time of the aircraft on the ground for its maintenance thanks to prototyping

When so used aircraft remain on the ground for their annual monitoring (which usually last a week or two each time), the suppliers of spare parts and maintenance services have to act quickly to ensure that these planes back in operation quickly.

"Our customers are very demanding," says James Deans, director of Airline Components International (ACI) Ltd, a company specializing in the design and manufacture of aircraft interiors.

"They send us your report requirements or parts of the interior of the plane and we carry out design, reverse engineering or again it to be manufactured before that the aircraft comes into operation." "The deadline that we have to do it can be matter of days".

When air carriers applying for a new aircraft a manufacturer such as Boeing or Airbus, several specialized companies are responsible for providing the Interior and other accessories. Said Deans, design and durability of these accessories are not maximum security, often impaired during its development in an effort to minimize the weight and the cost thereof.

ACI is an industrial design firm based in Oxfordshire (United Kingdom).

"A concept as a new seat design must be approved by the Department of marketing of the airline, but may block if deemed to be too heavy or too expensive", says. The commitment must be to use materials of plastic parts as the ornaments of the seat within the recommended tolerance. For example: a wall of 1,2 mm instead of 2 mm thickness can greatly affect the longevity of the pieces. The redesigned aircraft seat is introduced with the time in the manufacturing chain, but after a while, these components fail. "We also solve problems of design of other companies," said Deans.

For many years, ACI has employed its own machinery of FDM (fused material deposition modeling) to create design prototypes before relegating them to third-party vendors to produce the machining of steel and concluding parts of injection molding: this is a very beneficial way to save when the creation of the mould of production can be a long and expensive process.

"We knew of the existence of Proto Labs through a commercial publication of CAD." Initially, we were looking for a company that could produce larger prototype models that we could do in our facilities. We loved discovering that in addition to manufacturing pieces of molding by injection for prototypes, Proto Labs also could give us a production in the short run much more quickly and better than the traditional supplier of injection molding. "Then we realized that we had discovered something very important".

At that time, ACI was working on the creation of a project of pieces of molding by injection of large size for the Royal Air Force. "The machining of steel for this little project we were going to cost more than 222.500 euros and the final pieces would take to make a 12-16 weeks." Proto Labs told us that in only one, three, five or fifteen working days we could have in our hands a finished piece of moulding by injection in the same material of production we wanted and without that he would be harmed his performance for us was amazing! "."

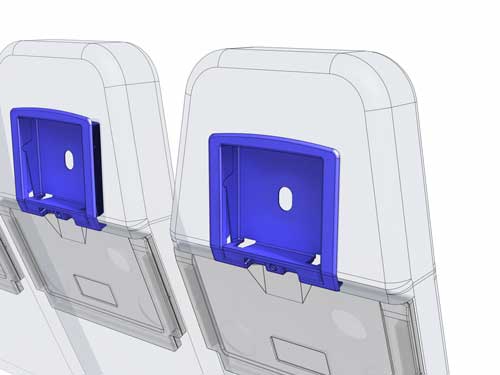

Since this first experience, ACI has been used Protomold to create a wide range of parts for many customers of airlines. Everything from parts for seats to boards for carpets, from kitchen to pieces for the top compartment, even lounging seats video environments.

"In recent years, ACI has invested in its capacity of design and verification" says Will Matthews, head of design. "This is where to add true value." In our facilities we have services of reverse engineering, analysis of finished elements and machinery for testing tension, pressure, wear, and testing of alternative load. "When a piece of ACI is ready to manufacture, it is considerably better than the original".

Matthews didn't realize the advantages of using the intuitive system of budget online in Promold, ProtoQuote. This system uses a previous model of CAD in 3D and a super multiterminal system used to process the model and the machining of the design, but States that it remains with that Protomold has a head of specialized project which can solve any problem and is impressed with the commitment of the company with a personalized service.

"When we put ourselves in contact with Proto Labs for any question or request, whether it's a new type of material, or if it is to modify anything design that can make easier the manufacturing of the piece"We always get the expected response and believe that Protomold is always very proactive, and what differentiates it from the rest of suppliers with whom we have worked. If in ProtoLabs do not know the answer at the moment, they investigate and get in touch with us very quickly. In our business, time is limited, so every hour counts. "We always know where we are with Proto Labs".