The 3D printing

March 11, 2009

3D printers use two basic components to "print": a special composite (similar to talcum powder) and an "ink" which has the property of compact the composite. Work area is an area of 25 x 35 cm (Spectrum Nokia), on which is dropped the composite uniformly and, subsequently, several similar to a home printer inkjet printheads launch the ink of different colors on the section of the model to compress. The 3D printer "prints" two layers of 0,089 and 0,203 mm each minute up to a maximum of 20 centimeters in height (the maximum size of the bucket).

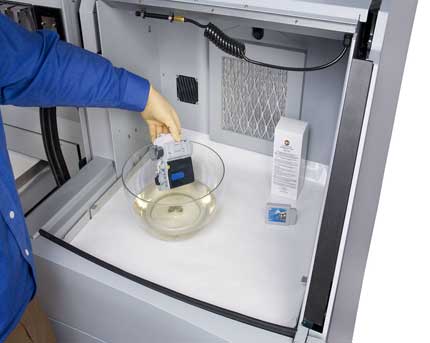

When it has finished printing and the model is complete, the remaining composite is aspirated and is recycled for future use, leaving the model clean and free of waste. At this stage of the process, the piece is still fragile and should be handled with care. To give the final finish, it is necessary to infiltrate her (submerge her) in one of the various infiltrating special adhesives, which increases the hardness and strength of the part of the prototype so it can be manipulated without special precaution.

Why use 3D printing technology?

3D printing technology differs from other methods of rapid prototyping (such as for example the creation of models through plastic injection) on several fundamental points. First of all, you can create models to full color thanks to the combined effect of the four heads of ink (magenta, cyan, yellow and transparent). The distribution of color is extremely precise, allowing label models with texts (design notes, tags,...), play trade marks, colored areas to differentiate them, etc. Models and models are fully colored printer, without the need for laborious downstream processes.

Secondly, the time it takes to finish a piece varies depending on the size and complexity of the same, but in all cases the 3D printing is the technology for faster creation of prototypes of the market (between 5 and 10 times faster than any other solution). In addition, several independent prototypes simultaneously can be printed out to take advantage of all the printing surface.

Finally, print materials are cheaper than other solutions for rapid prototyping, which makes the 3D printers very suitable machines for continuous production environments. It's a machine capable of producing models of quality with a high market value and a really low production cost. With other solutions, reserves the creation of a prototype for the more advanced stages of the design process or even the final stage of presentation to the client. The low cost of this technology allows models in several intermediate points of the design process.

CADdy Spain 3D printer models:

-ZPrinter 650 - 3D printer at highest level in the market.

-ZPrinter 450 - 3D printer's Office.

-Spectrum Nokia - production color 3D printer.

-ZPrinter 310 Plus - the incorporation into the monochrome 3D printer.

Applications:

-Conceptual models

-Models for presentations

-Finite element analysis

-Functional checks

Industries of application:

-Architecture (AEC)

-Topography (GIS)

-Packaging

-Household appliances

-Education

-Molecular modeling

-Automotive

-Footwear

-Modeling for medicine

-Medicine