This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

El papel de las boquillas en la reducción de los tiempos de producciónSystems Stack Mould to seal with conflicting nozzles

The role of the nozzles in the reduction of production times

The always greater expectations of the customers concerning the aesthetics of the product make the quality of the nozzles and the reduction of production time to assume increasing importance. At the same time, the reduction of prices, the reduction of the life cycle of products and the increase in the requirements qualitative, caused by the intense market competition, increase lately the demands of the customers in the decisions of the deployments of hot channel injection.

One of the new Thermoplay (represented in Spain by O.C. Systems) has recently developed a type of channel hot 'stack mould' with nozzles that incorporate shutter. Thermoplay has a long experience in the project, development and realization of 'hot half' (hot half) with grout and seal groups, which are usually mounted on the plate of distribution, being these external and separate groups with respect to the injectors.

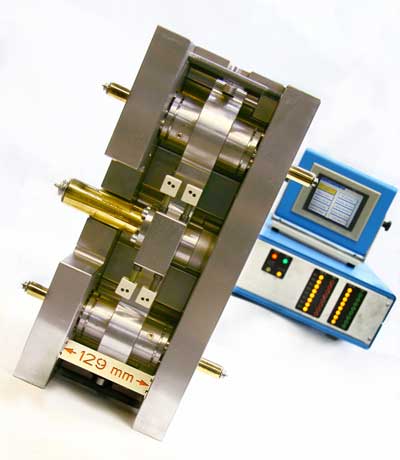

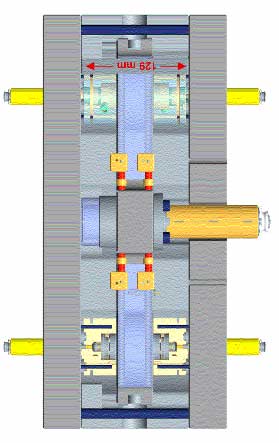

The examples illustrated in the images refer to two systems Stack Mould in which has been recently implemented this new concept, with 4 + 4 nozzle with Cap elongated seal (type DN3B) of diameter 30 mm and length of 126 mm.

The characteristic of this innovative product is that the Group's seal is integrated inside of the nozzle, is part of it. This new principle has been studied and designed to minimize the space of the hot channel on the inside of the mold, and can thus obtain a reduction in the height of regles them up to a total of 129 mm, complete package.

It also allows a single plate of distribution inside the Stack Mould where shutter groups are installed in opposed mode, while the traditional systems of this type only carried out with two parallel distribution with a distanciadora plate in the middle of these.

Types of nozzles used for this application are equipped with a group of seal with pneumatic drive and they can have a diameter of 16 mm or 24 mm and lengths up to 206 mm.

The typical application of the nozzles with shutter in 'stack moulds' is in respect of the packaging, where thin thicknesses are required high volumes of production and reduced costs

In addition, diameters and lengths on request can be made.

The typical application for this type of 'stack mould' is high volumes of production and reduced costs in respect of the packaging, where thin thickness, are required. The aesthetic appearance of the pieces in this sector is very important and injection site that leave the grout to seal is little visible and very polished, making it especially suitable for this type of applications.

Thermoplay also offers the sequential control box for the closure and opening of the valves for seals on the molds that produce large pieces or molds with pieces of different volumes together.

Sequential control allows to obtain parts injected by several points without visible signs of joints of material, and also using a press with reduced clamping force. The result is certainly the contain and reduce the costs of production of plastic parts.

Related Companies or Entities