“The technologies composites will happen of the vehicles niche to the half series and, in a future, to the big series”

Interview to Javier Martínez Cue, director of R&D of FPK Lightweight Technologies

Partner And provider of the main manufacturers of trucks,

Javier Martínez Cue, director of R&D of FPK Lightweight Technologies.

FPK Designs and supplies structural and aerodynamic components in composite or in plastic reinforced…

Yes, want to help to our customers to reduce broadcasts well through the saving of weight or through the aerodynamic improvement. FPK Is a line of business of the group Batz and are framed in the corporation Mondragón. At present we have 3 locations, in the Basque Country, in Germany and in Brazil. The idea is to industrialise our products in new locations where the line of business Batz Systems explains at present with plants of production.

In bold strokes, why it pursues achieve vehicles lighter?

Exists a direct relation between the weight and the consumption of fuel. They work several lines to reduce the consumption of fuel and, therefore, of broadcasts of CO2. One of them is the improvement of the efficiency of the motorisations and the another is the aerodynamic improvement of the product. Besides, a third line would be the aligeramiento of weight, that each day earns more importance.

It is the plastic the best alternative?

The composite is one of the alternatives, but also work light alloys or aluminiums, between others. But, definitely, the composite or plastic reinforced little by little wins terrain and has an increasing importance, when combining a high degree of freedom of design with the lightness of the materials.

What remains him for conquering to the plastic in the vehicle?

The structure of the car, although we already have examples in the market: the model i3, an electrical car of BMW that has his monocasco autoportante elaborated in carbon, a thermostable reinforced with fibre of carbon. To day of today, these materials and technologies have prices very high, by what are tied to vehicles niche, to short series, like the i3. But to measure that evolve the technologies composites and, especially, reduce the prices of the raw materials, will see as they go happening of the vehicles niches to the half series and, in a future on a long-term basis, to the big series.

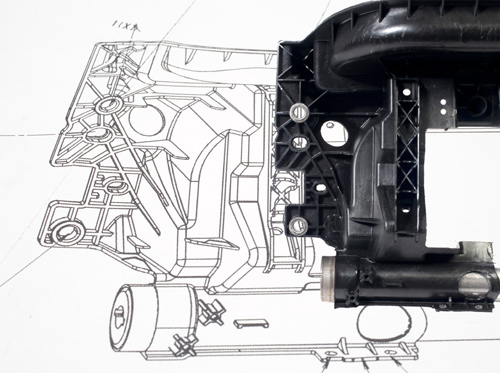

Cockpit loaders.

There is the one who affirms that it will arrive a moment in that even all the acristalamiento will be of polycarbonate. What think in this regard?

Think that it will attain but that will cost to convince to the manufacturers. This is one of the main difficulties that also find in the structural part. For a structural piece key, a component of hygiene or very technical, the do a first evolution of the metal to the plastic reinforced, supposes a way of very long route because it is necessary to show very well that works.

It show you that works. How it would defend the plastic in front of another resistant material?

The plastic fulfils the requests and ideal specifications to attain a lower weight. Regarding the mechanical function, the advantage achieves through the freedom of design. Although the unitary mechanical properties of the plastic are inferior to the metal, compensates with an equivalent rigidity, even upper, and a good resistance, through the geometry or the design, between other properties.

It has influenced the proliferation of the electrical vehicle in the research of new formulas that lighten the pieces?

Yes, in several appearances. In the first place, they have presented opportunities for new components related with the storage of power, supports of battery, among others, adapted to the architecture of the electrical vehicle. The second question is that the saving of weight is even more important that in the vehicles of internal combustion because clearly in this, the weight goes against the provision. Here the receptividad of the manufacturers of trucks to enter in the research of materials with light technologies is greater.

I understand…

On the other hand, see that by the moment the opportunities for the electrical car keep on being for volumes very small and that, in some cases, what has done is “tunear” the architecture of a car, of a conventional motorisation, to enter the electrical engine and the storage of electrical power. I think that in the future there will be architectures thought for specific series bigger, by what can that they present new opportunities of compound materials.

Then, what future augura for the electrical vehicle?

The specialists think that his implantation goes to be very slow. They speak of percentages and volumes still small from the year 2020. It will be a way that will give enough more slowly of what predicted ten years ago.

By the little autonomy of the battery?

Yes, and also by the infrastructures, especially the pure electrical vehicle, since it is very dependent of the points of load and is not easy to give with a solution.

Also it exists a greater awareness by the respect of the environingingment. It has propiciado the use of new materials that allow to be recycled?

Exists a direct relation between the saving of fuel and the broadcasts of CO2. There is a market also of plastics recycled quite consolidated in Europe for materials commodities like the polipropileno and the polyamide. With the use of materials recycled the manufacturer of trucks can obtain a reduction of interesting costs and contributes to the environingingmental improvement.

One of the decisive axles of innovation in the plastic industry for applications trucks is the development of materials. Which are the more employees and with which works FPK?

To day of today, the more employee is the polipropileno, the commodity more usual, cheaper, more abundant in any market and, besides, a very amicable material to the hour to transform it. It follows him the polyamide in our field of structural and functional pieces.

Afterwards would go in in the technical plastics, in which there is a potential of saving of weight a lot greater, although his application is only viable in those applications with a greater request, because of the price of the prime matter.

You offer solutions of light structural components for the fronted loaders, cockpit loaders, the cavity of spare wheel and the box of battery. What proposes FPK and which advantages obtain in each piece?

We offer solutions in several lines. We are working in the research of materials of better applicable mechanical provision to current technologies already industrialised. In base to these improvements can do viable determined components or products. Also we work with thermoplastic technicians and with fibres of carbon.

And in the field of the technology of the plastic?

On the one hand, pretend to expand the technologies industrialised generating new technological variants that contribute advantages in the mechanical behaviour of the product with the integration, for example, of reinforcements of continuous fibre in the process of injection. They are, in principle, adaptations of existent technologies and, therefore, of relative easy implementation in the series.

Also they develop new technologies…

Yes, work in the development of innovative technology, with a horizon to half term, that allow a greater level of integration of functions of the pieces, a greater complexity and also abaratar the product, being able to integrate the manufacture of the prime matter in the process and, in definite, reduce the cost of the final product.

They work with bioplásticos?

Know them but to day of today find them very expensive in comparison with the conventional plastics. They are bio and no derived of the oil, but still is for showing if the environingingmental impact that generates the production of his raw materials improvement the one of the conventional materials. Nevertheless, the elder hándicap that find is that for the moment they are expensive in comparison with the conventional plastics.

They are not in his line of performance…

No, however, if under demand of some manufacturer of vehicles, have to use a polymer of origin bio, the technologies are prepared. Really, there is prime matter, especially polyamides, that can transform by conventional injection, but his cost is high.

Would have felt a biodegradable plastic in the car?

Up to now have asked us that the components do not fail and guarantee the life of service in the vehicle. It seems a contrasentido say that the piece can disintegrate . We believe more in the recycled, like way to minimise the environingingmental impact, as well as in designing the components so that they are but easily recyclable.

In some cases, the piece composes of several plastics of different typology. It does not pose a problem to the hour to recycle it afterwards?

Usually composes of an only plastic. There is a minority of pieces that are bimaterial and have metallic elements. These assemble and atornillan and, in occasions, sobreinyectan. Recycle this type of components is a challenge. Separate the sheet of the plastic is viable and does not do fault a technology complicated for this, however, economically no always is profitable the separation of materials in these products, therefore in occasions this type of complex components finish in the dump. The tendency —no only by the saving of cost and weight— is to try develop components monomaterial and without metallic reinforcements so that they can disassemble easily.

Can put an example?

An usual case of FPK is the frontal. The support of setting of the lighthouses, radiator, the lock, capota, bumper etc. Treats of a piece that during a lot of years has had in Europe a hybrid design, of metal and plastic, combined in a process of moldeo by injection. These sheets can separate by presses or triturando the pieces and separating magnéticamente or by decantation, but as it said, to the hour to do numbers, no always compensates.

It thinks that the reciclabilidad of the components is an appearance that concern to the manufacturer of vehicles?

Yes, concerns them. It is not in the order of importance of the weight of the component or of the cost but yes, the recycled concerns them. In fact, there are manufacturers that have some specific norms to the hour to manufacture the pieces so that afterwards they can disassemble or desensamblar and separate material to recycle.

Besides, they work in the field of the aerodynamic components for the capsules under engine, low coatings flat and deflectors and components of panelado…

Yes, are components in which, except vehicles niche of the type 4x4, there has not been transition of the metal to the plastic. They are solutions added to achieve an aerodynamic improvement of the vehicle, a species of streamlining that mounts in the basses, and have a triple function: aerodynamics, protection of the basses and of the engine of the vehicle and an acoustic function. If it exists an important nuance in this type of pieces is, in addition to the aerodynamic improvement, attain be very competitive. The technologies that use to manufacture pieces combine the transformation of the plastic with the manufacture of the prime matter.

Stand out some solution of which offer, by his importance or complexity…

If it had to stand out two, on the one hand resaltaría a component consolidated in plastic reinforced in Europe, the frontend. Almost all the European manufacturers of trucks have frontend of plastic or hybrids in his different models. They stand out two questions: the cost and a saving of weight of until 35% in front of the metallic solution. It achieves a saving of interesting cost by the integration of functions, achieving realizar a piece with a lot of functions in an alone hit of presses of injection.

And the second?

Although it is not a component consolidated, would stand out the support of signpost of instruments, a piece that integrates a big quantity of functions and a component of hygiene very technical with requests of crash dynamic. It is situated underneath of the board of instruments, is the group that bears the board of instruments and all the elements related with the cockpit, the column of steering, the airbags of passenger, the box of heating… Is a very interesting application in which we have worked and follow working.

Which technologies employs FPK to achieve components of automotive sector lighter?

At present in manufacture have five technologies: SMC, GMT, LFT, IMC and conventional injection. Basically they are classified in technologies in moldeo by compressesion and in technologies in moldeo of injection. In both cases also have technologies in which we form a semiproducto and turn it into pieces as it is the case of the SMC, GMT or the conventional injection and others, where integrate the manufacture of the prime matter in the own process of moldeo in continuous.

Speak us of his projects of future.

Are immersed in a phase of globalisation. Until four years ago, FPK was an only productive plant, but, after integrating us in the group Batz, now have other two productive centres. We work so that the products of light weight also industrialise in the others plants of the group. Probably it was our more difficult challenge in these moments. Besides, we pretend to develop innovative products.

Which type of products?

Want to substitute the metal by the plastic in pieces of first evolution that never before have developed in composite (in series half or big). Here the key are the new materials, material optimised or the variants of the existent technologies.