The Ultramid-To3X of BASF ensures like an economic and functional alternative to the products of m-PPE

Comparison between adhesions of silicone and adhesive stravel of acrilato in applications of the technology of photovoltaic connection

Florian Müller and Stefan Mochev, Division Engineering plastics Europe,

The photovoltaic industry crosses at present by a phase of consolidation. The national manufacturers have in this moment that bear, in addition to the cuts in the prices of reward of the supply, the pressesures in the costs derived of the import of cheap photovoltaic panels pertinent of Asia. At the end, only they will be able to keep companies that employ new technologies and face costs of low production.

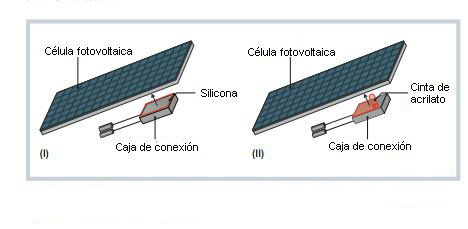

A possibility of economizar productive costs offer it the adhesive stravel that employ to fix boxes of connection to crystalline solar panels or of fine layer. In comparison with the adhesive of usual silicone, in this case results possible to save the high times of hardening. From it does some years, the BASF, with his marks Ultramid-To3X, comes offering fireproof polyamides (PA) like alternative to the products established of polifeniléter modified (m-PPE) and polycarbonate (PC) with seen to his employment in the technology of photovoltaic electrical connections [Figure 1]. In the frame of an exhaustive analysis, has subjected to essay the compatibility of the systems of adhesion with the different types of plastics.

Requirements and regulations

The photovoltaic installations dimensionan by general rule foreseeing offer an useful life of 25 years in hard environingingmental conditions. Because of this, the materials employed in the technician of electrical connection of photovoltaic panels have to be, in addition to highly antiinflamables, resistant to the intemperie, and in particular possess a good resistance to the impact to the low temperatures. This type of plastics, in effect, have to fulfil the requirements of no-inflamabilidad specified by the standard UL 94, class of protection against fires 5GOES [rule of the Underwriters Laboratories of the EE UU], in whose case the essays realizar , in comparison with the categories V0 to V2, with powers of flame ten stronger times. The assessment of the resistance to the impact to low temperatures effects of compliance with the specified by the cold-impact-test [UL 1703]: this proof surpass it components that to -35 °C do not present neither fissures neither any another type of flaws after suffering the impact of a sphere of 535 g of weight from a height of 1,3 m. Also they pose requirements related with the resistance to the ultraviolet radiation [f1 outdoor use: UL 746 C] and to the hydrolysis [85 °C / 85% of relative humidity during 1.000 hours: IEC 61215; it appears 2].

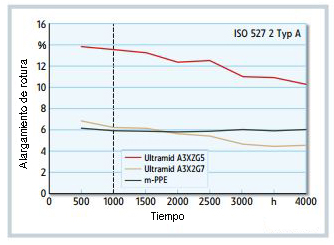

Considering the high requirements, it is evident that BASF offers photovoltaic solar energy industry types of material which are crediting his services in the electrical and electronic sector for years. Among them are the Ultramid A3X2G7 degree and modified the Ultramid A3XZG5 impact-resistant material.

Apart from raw materials, BASF offers its customers a complete advice service, composed, among other things, competition of CAE (computer aided engineering) and design and testing of components. This are a good example the analysis of adhesion to which BASF has submitted in especially the junction boxes with self-adhesive tapes of acrylate, on the occasion of a discussion that took place in the presence of specialized public.

The trials aimed to assess adhesion of polyamide and other plastics for routine use with different acrylate adhesive tapes, which is at the same time employed different methodologies for preliminary treatment in each case. For purposes of comparison was made also to the results of trials with adhesives silicone [Fig. 3], which have been used mainly to date for join boxes connection with photovoltaic panels.

The testing and results

In the analysis were conducted two essentially different series of trials together, respectively, applied to silicone adhesives and acrylate adhesive tapes.

Silicone adhesives

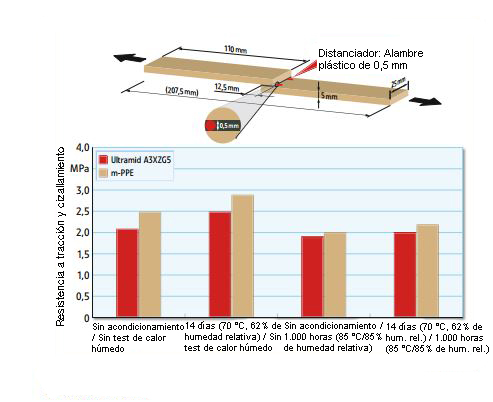

Of a part, hit samples of essay of Ultramid To3XZG5 or polifeniléter modified (m-PPE) with adhesive of silicone RTV1 available usual in the market [with reticulación to temperature acclimatise, monocomponente], subjecting them to efforts of detachment, that is to say, checking his resistance to the traction and to the shearing [figure 4]. The analysis effected with dry plastic and conditioned, as well as no-aged, subsequently to a storage of 1.000 hours to 85 °C and 85% of relative humidity of the air, without that observed significant differences between the plastics subjected to essay. Worthy to notice is that in this test produces always a fracture cohesiva –a collapse in the adhesive same of silicone–. The union between the plastic and the adhesive remained, then , intact after the proof, by what has to value it as very good.

Acrylate adhesive tapes

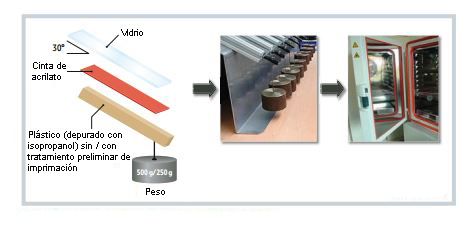

When fixing junction boxes with acrylate adhesive tapes [also called 'tapes' acrylate] tested, different plastic samples - of which only a part of them had been treated preliminarily with a coat of primer - were attached to a glass with different tapes. For starters, the samples were subjected to a constant load in different temperatures. In this test, known as 'dry-heat-test' (dry heat resistance test) broke from a temperature of 50 ° C, rising later this value 10 ° C every 24 hours until the collapse of the samples. A second series of tests [Figure 5] included the measurement of adhesion after storage in humid heat environment [85 ° C / 85% RH]. In the tests, therefore, were not measured resistance, but the collapse to a defined temperature [Fig. 6a] or after a period of time preset at will [Fig. 6b].

The results came to indicate enough that the polymer substrate is subject to a preliminary treatment of primer regardless whatever the used plastic. The primer is cause of chemical bonds between substrate and adhesive tape, being thus improved adhesion and generating a protective barrier against moisture.

In absence of primer, all plastics subjected to the test occurs in an adhesive fracture at still moderate temperatures between 50 ° C and 100 ° C, being, in other words, dissolved the union between the plastic and adhesive. On the other hand, carried out tests with plastic samples provided with a layer of primer, in some cases up to temperatures of 160 ° C not arise any fractures, while in others the unique result is a cohesive fracture in the tape of acrylate, maintaining the union between plastic and adhesive. Only in a few cases collapses the accession, and this only at elevated temperatures. Differences are appreciated either between the different types of plastics. Used tapes were sticky foam tapes current market sale acrylate, and primer products used the recommended by the various manufacturers of straps.

Considering the results obtained in the trial of dry heat (dry-heat), the analysis type damp heat (moist heat), much more severe [Fig. 6b], was carried out only with samples that had applied a primer. Here could already observe is clearly the differences between the different tapes. While all the plastic samples exceeded without problems the union with tape 1 for 2,000 hours in a climate of humid heat, the behavior of plastics varied significantly with 2 and 3 tapes. Yet, nor here was the different types of plastics to create a fundamental influence.

Conclusions

The plastics subjected to essay can hit all they with the usual adhesive stravel the same of well that with the adhesive of silicone RTV1 classical. The differences between the plastics are not significant. The types antiinflamables of Ultramid To3X [PA] show an equal level of high that the polifeniléter modified [m-PPE] and the polycarbonate [PC]. Instead, yes they warn evident differences between the different systems of imprimación and the adhesive stravel.

This means that the boxes of connection of plastic can fix well with adhesive stravel of acrilato and silicone independently of which was the polymer employed. Nevertheless, with the end to obtain optimum results would have forzosamente that harmonise between them the preliminary treatment and the adhesive strip or the adhesive of silicone employed, a phenomenon that results already very known by other sectors of the assembling of materials. Having always present the specifications of the manufacturers, the adhesive stravel constitute, then , an alternative to the adhesive of silicone, because with his help can delete the high times of hardening, seeing like this reduced the costs of production.