Manufacture of pieces for the interior of the car

This last line of investigation is in accordance with the increasing demand of biodegradable materials or of renewable origin like alternative to the employment of the traditional plastic materials. In the last fifteen years, has gone out to the market a wide rank of new biodegradable materials and/or of renewable source for diverse applications. For example, they exist different commercial degrees of materials based in starch or biodegradable polyesters that come employing in the sector of alimentary container. However, in the case of the industry of the car, still requires more investigation to arrive to develop material adapted for his processed by means of the technologies of moldeo by injection and termoconformado, the mostly involved processes in this sector, that fulfil with the requests for his employment so much in the outside as in the interior of the vehicles. Appearances like the thermal sensors resistance, the mechanical provision or the broadcast of volatile components managers of the apparition of smells in the interior of the vehicles have to improve for these materials.

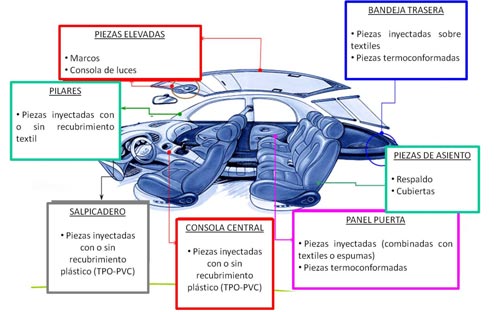

Since it exists a big variety of pieces of interior of car, also are multiple the requests that have to fulfil the materials employed in his manufacture in accordance with the corresponding specifications. The figure 1 sample the different components manufactured in the actuality with plastic materials that form part of the interior of a vehicle.

Inside this line of investigation freamers the European project Ecoplast, of title 'Research in new biomass-based composites from renewable resources with improved properties for vehicle parts moulding', coordinated by the Technological Centre of the Automotive sector of Galicia (CTAG). The project, of four years of length, has like main aim the development of new biocomposites based in biopolymers and reinforced with natural fibres, nanoarcillas or mineral loads, adapting the conventional processes of transformation of plastic materials commonly employed in the industry of the automotive sector and other technicians of processed innovative, to reach the requests for his validation and his employment in the interior of the car. The new biomateriales to develop inside the frame of the project are based in two biodegradable polyesters, sour poliláctico (PLA) and polihidroxibutirato (PHB), and in a new copolymer based in natural proteins. On the other hand, in the project contemplates the manufacture of components of the signpost of the door with the new materials. The figure 2 sample the detail of diverse components of a door of car.

The consortium of the project is formed by 13 partners, between which form part 4 centres of investigation (Aimplas, CTAG, Fraunhofer Umsicht and PIEP) that collaborate together with small and big companies, covering all the chain of value of the final products to develop in the project: manufacturers of raw materials, in concrete bioplásticos (Biomer, Purac, Nanobiomatters, University of Uminho), compounders (FKUR), manufacturer of equipment (Pallmann) and companies manufacturers of pieces of automotive sector like final users (Group Antolin, Megatech).

Aimplas, the Technological Institute of the plastic, in Valencia, with big experience in the development and processed of plastic materials, exerts the following roles inside the project Ecoplast:

• The improvement of the provision of the PHB for his employment in interiors, in concrete the reduction of smell and of volatile components by means of the use of new technologies of processed as it is the use of carbon dioxide in state supercrítico (sc-CO2) in a process of extrusion.

• The study of processed by extrusion and termoconformado of the new biocomposites based in PHB.

In these moments, the project carries two years and half of investigation, time during which have developed different formulations that are optimising for the fulfillment of the requirements that demand determinate pieces of the interior of the vehicles. In the next months is foreseen to realise the proofs of escalado industrial in the companies final users employing the most suitable formulations, as well as his back validation for the planned applications.

The achievement of the aims of the project Ecoplast will allow to the companies manufacturers of pieces of car participants differentiate inside his sector.

Gratitudes

The project Ecoplast 'Research in new biomass-based composites from renewable resources with improved properties for vehicle parts moulding', of the VII Program Marco is funded by the European Commission inside the area NMP (Nanosciences, Nanotechnologies, Materials and New Production Technologies).

To the Consortium of the project: CTAG, Fraunhofer Umsicht, PIEP, University of Uminho, Aimplas, VTT, Purac, Nanobiomatters, FKUR, Biomer, Pallmann, Megathech and Group Antolin.

For additional information: