Hot channels, a technology in constant evolution

Daniel Vizuete Andújar, responsible of sales of

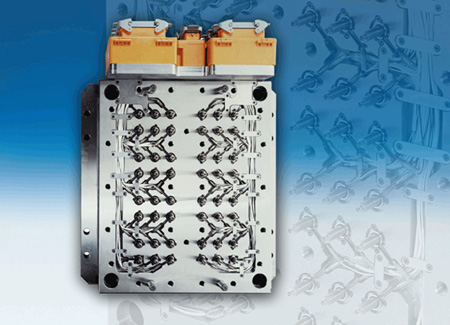

The sector of the injection of plastic is evolving quickly, by what the needs and requests of the pieces of plastic regarding materials and costs force to use new technologies and strategies to face successfully the new challenges. “Like providers of the sector this demands us the adapt us to the new requests using the best materials and technologies to guarantee the reliability and durability of our systems of injection from the unitary filter until the most complex systems of 64 filters with obturación accionadas with servomotors, going through systems of hot channel apilado, asymmetric or multimaterial”, affirms Daniel Vizuete Andújar, responsible of sales of

As it explains, like providers of systems of injection his main aim is the one to supply in each case a specific solution to attain the maximum performance. Thus, they have different types of filters to incorporate to the system of injection or use individually, depending of the material to process. Each one of the different types of filters combines different models of leading to guarantee the best quality of point of injection in any application, from poliolefinas until resins of engineering very abrasive and that require high pressesure.

The importance of the filters

Without subtracting him importance to the responsibility that recae on the blocks distributors, for Vizuete, the filters are the most critical point of a system of injection, especially in the processing of technical materials. These are the link between the block and the cavity and, depending on his geometry, his mass, contact with the mould, reading of the temperature or material used in his construction, will affect in elder or lower degree to the quality of the piece, appearance of the mark of the point of injection, time in the changes of colour or time of cycle.

The hot channels and the improvement of the production

With the current situation of the market of maximum competitiveness, the inyectadores and manufacturers of moulds need solutions of systems of injection that are reliable, that maximicen the repetitividad and that improve the efficiency of production for all type of applications. “The current systems of hot channel can offer him all these requirements and, besides, a considerable reduction in the costs of production”, sustains Vizuete.

Between other advantages, this type of systems in the actuality simplifies the construction of the mould and improves the quality of the piece. But, for manager of sales of

Hasco+R&D

The investigation and the development is a fundamental “part” of Hasco. “Always it has recognised us by the big quantity of innovative products and of high performance of our catalogue. For this, the best way is to invest in R&D and surround of the best collaborators like universities, technology centres and, as no, of our own customers”, affirms Vizuete. The department of R&D of the company has his own pilot plant, in which the new products subject to exhaustive proofs before determining if they launched to the market. Besides, it has agreements with important inyecctadores to which builds them moulds in which it incorporates his products in phase of development so that they can determine and guarantee the reliability before incorporating it to his catalogue.

The adaptation of the technology

From the systems of hot channel originals until the current, the evolution has been constant and have improving fundamental appearances like the design balanced, the profile of temperature, the driving of the material, the longevity and reliability of the components, as well as the controllers of temperature, that, for Vizuete, are a fundamental “part” in a system of hot channel: “Without his evolution could not face up with guarantee to the requests of a lot of processes of production that today present us ”.

The moulds will continue being increasingly complex and, therefore, the systems of hot channel and his components will have to follow improving to adapt to the new requests. Another appearance that stands out the manager of sales of Hasco Iberian, S.L.Or. It is that the terms of delivery will be even more reduced, by what the manufacturers will have to work in this line, offering components easier to adapt to the project and, at the same time, more specific to each sector of market to attain a maximum performance. “We have to provide the information of design more quickly and be able to coordinate projects of effective form on a global base, offering besides a near and agile service of local form”, aims Vizuete.

On Hasco

From his origins, 90 years ago, as small workshop artesanal until our days, as one of the main providers of the industry of the mould all over the world, Hasco it looks for the efficiency and the quality, values that, added to a cooperative service oriented to the customer, determine “the success of the company and the one of his customers on a long-term basis”.

The division of systems of hot channel of Hasco is “synonymous of experience” in the moldeo by injection and, thanks to his work of vicinity with the customer, achieves to supply systems of reliable injection and perfectly adapted to the requests of the piece, of the process of injection and to the needs in the construction of the mould.