ECO RUBBER: Crumb recycled rubber as a raw material for new urban furniture products

Nowadays, horse arenas for dressage, animal pens, and fillers for sports equipment are among the applications that are made from recycled tyre crumb rubber chips Crumb recycled rubber is also used together with binders to manufacture children’s flooring to provide protection in playgrounds. Up to 20% of binders (adhesives), generally polyurethane prepolymers that react with diisocyanates, are added for manufacturing agglomerated rubber products. Other ingredients (fillers) such as carbon black, softeners and surfactants are used to stiffen or strengthen the rubber, to improve the workability of the material and to enhance some properties such as UV or fire resistance. The use of chemicals may prevent further recycling and may cause problems in some applications when these products are used (as in the case of coming into contact with children)

Up until now, no crumb recycled rubber application in high quality products using recycled rubber as a main raw material existed., However, the first crumb recycled sintered product, a bollard, has been manufactured. To develop this product AIMPLAS, Instituto Tecnológico del Plástico, is coordinating the ECO RUBBER project, together with Instituto de Biomecánica de Valencia (IBV) and the enterprises RECIPNEU - TYRE RECYCLING NATIONAL ENTERPRISE LTD and BERLÁ, S.A.

The main goal of ECO RUBBER has been to adapt the current industrial rubber recycling process to supply innovative recycled rubber urban furniture products manufactured by an innovative sintering process as an alternative to virgin rubber, wood or concrete products.

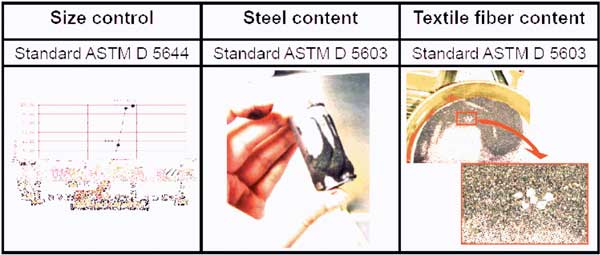

The crumb recycled rubber obtained in current grinding plants is not suitable for the sintering process. It was necessary to adapt a grinding line to obtain a crumb recycled rubber with the appropriate requirements for the sintering process; with a narrow distribution, rough surface and zero contaminants (textiles fibber, steel, sand…). This adaptation was the first step in the project. Currently, the design, selection and assembly of grinding ferrous and textile decontamination and size separation equipment has been completed. The optimization of the grinding process is nearly finished and RECIPNEU is starting the industrial production of optimized crumb recycled rubber.

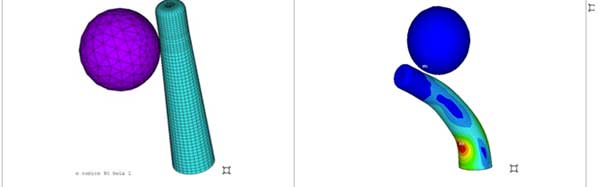

A bollard was chosen as the urban furniture application to be developed within the project. this choice is due to the fact that a bollard made of recycled rubber represents the advantages of an urban application made of recycled rubber, mainly because the material’s elasticity might reduce the risk of injuries as a result of hits or accidents and it is believed that a high potential market demand exists for this product.

Furthermore, due to the variety of materials bollards are made of, it will be possible to obtain the advantages of the recycled rubber bollard from a bollard made of other material such as, for instance, steel. Once all specifications regarding standards and characteristics were obtained, a preliminary bollard design was proposed, being optimized by means of a Finite Element Analysis (FEA) by IBV. Based on this, the final bollard design was selected and the mould design and construction took place.

In the sintering process proposed in the ECO-RUBBER project, high pressure and temperature is applied over a closed mould filled with pre-heated ground recycled rubber together with some additives to make the rubber molecules become cross-linked and to obtain consistent material. Referring to the sintering plant facilities, nearly all the equipment has been designed, selected and assembled, having manufactured the first production series in order to assess the production line and start with the optimization phase. Furthermore, it was demonstrated that the addition of additives to the base crumbing material improves the properties of the bollards and the final formulation at industrial level is currently being developed at BERLÁ’s plant.

To eliminate the emotional barriers which stem from the use of urban furniture made of recycled rubber, an eco-label will be placed on the bollard, showing the benefits of the use of this kind of recycled material. However, there is no recycled rubber eco-label at a European level so, after reviewing all the existing rubber eco labels throughout the world and based on their requirements, it was agreed to complete an environmental self-declaration of the bollards and to apply for a new eco-label group to include a European eco-label of recycled rubber products.

From an environmental point of view, the ECO RUBBER project will contribute to divert the end-of-use tyres from landfilling and incineration to recycling and to reduce the quantity of natural resources to be used in the rubber manufacturing process. Crumb recycled rubber, developed within the ECO RUBBER project, could be a valuable alternative to the use of natural or synthetic rubber for obtaining a wide range of commercial and industrial products that do not have very high technical requirements including some types of rubber wheels, rubber buffers and cycle track separators. This will allow the manufacture of sustainable products decreasing the final price and, as a consequence, being more competitive in the market.

Based on previous Life Cycle Assessment, where recycled rubber was compared to Styrene-Butadiene Rubber (SBR), it was concluded that the new products developed according to the sintering process in the ECO RUBBER project, will have a lower environmental impact compared to those made of rubber, reducing around 88% in energy consumption and 72 % in greenhouse gases emission. Furthermore, the products made of recycled rubber will present recycled properties. This means that the used product could re-enter the grinding /sintering process proposed in ECO-RUBBER, obtaining a new product with similar properties to the previous one used as a raw material for the grinding process.

These environmental advantages together with market expectations encouraged the consortium to implement the industrialization process that is described in this article.

ECO-RUBBER “Innovative used tyres recycling and rubber sintering process for eco-friendly urban equipment fabrication” is a CIP Eco-innovation Pilot and market replication project. (ECO/08/239112/SI2.535300). The project has a total duration of 36 months (from July 2009 to December 2011).