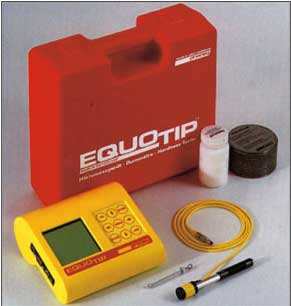

1975-2005. El método Leeb y Equotip: una revolución en los métodos de medida de dureza

En 1978, a instancias de Proceq, Dietmar Leeb publicó el ensayo científico “Nuevo método dinámico para ensayo de medidas de dureza en materiales metálicos”, con el que el valor L se dio a conocer internacionalmente y popularizó el uso de Equotip como método de control de calidad.

El valor L es un valor de dureza equivalente a un cociente invariable (1) que, desde 1996, se encuentra normalizado por la agencia norteamericana de normalización ASTM. La norma ASTM A-956, que desde su aprobación ha tenido tres revisiones, recibió inicialmente el nombre de “Método normalizado Equotip para la medida de dureza en acero”. En 2002, sin embargo, modificó su nombre al genérico “Método normalizado de Leeb para la medida de dureza en acero”, por la presión de fabricantes de las copias del instrumento original que se han multiplicado por el éxito y fiabilidad del método.

Hay que destacar, sin embargo, que pese a que la expiración de la patente ha permitido la aparición de algunos instrumentos prácticamente clónicos de Equotip en colores, denominaciones y método de funcionamiento, los rangos de incertidumbre de estas copias son mucho más elevadas que las del aparato original. Equotip de Proceq es el único durómetro portátil de medida según el método Leeb que sigue manteniendo una precisión de medida de +4 HL en todo el rango de dureza. La ratio de velocidades de golpe y retroceso del instrumento de impacto, base absoluta del método, sigue siendo patrimonio de la empresa suiza, por lo que el resultado de medida con este durómetro se ha mantenido constante sobre los mismos materiales medidos con unidades de las cuatro generaciones de Equotip que desde 1975 se han vendido en todo el mundo.

La proliferación de copias, lejos de popularizar el método, ha abierto ciertas dudas en algunos usuarios sobre su bondad, ya que los numerosos aparatos baratos que han invadido el mercado sólo se comportan adecuadamente sobre los yunques y probetas de control, pero resultan inefectivos para durezas mayores o menores. En este sentido, Proceq ha abierto varias campañas informativas advirtiendo sobre el peligro de suplir sus instrumentos de impacto calibrados por clones. “Tarde o temprano, las buenas ideas se copian” fue el slogan con el que la compañía suiza advertía por primera vez de la aparición de instrumentos y repuestos inefectivos que, sin rubor, copian denominaciones, apariencias y colores de los Equotip originales.

General Electric Power Energy, Aceralia, el grupo Soluziona, ATISAE, SGS, Schindler España, ABB, Iberdrola, son algunas de las empresas radicadas en nuestro país que hacen uso del Equotip original de Proceq en sus departamentos de verificación y control de calidad. Desde hace más de 30 años, los primeros Equotip y su segunda generación, con su unidad de control exagonal roja, han sido referencia de calidad de medida en acerías, empresas de tratamientos térmicos , fabricantes de grandes piezas y cadenas de montaje en España. Desde la aparición de Equotip 2, con su unidad control amarilla característica, cientos de durómetros portátiles de Proceq han contribuido a facilitar la medición de dureza de metales en España, ampliando su rango de actuación a aluminios, fundición gris y nodular, bronces y aleaciones especiales.

En la reciente BIEMH 2004, a los siete instrumentos de impacto tradicionales de Equotip –el estándar D, el de punta estrecha D+15, el de lugares de difícil acceso DL, el de interiores DC, el de piezas masivas G, el de punta de diamante para grandes durezas E y el de materiales blandos C- se les ha sumado el instrumento S, con una actuación diez veces más prolongada que la del instrumento estándar, con lo que Equotip alcanza sus 30 años como el durómetro portátil más versátil, fiable y copiado del sector.