Interview with Andrzej Grzesiak, director of the Fraunhofer Alliance on additive manufacturing

on June 14, 2011

What are the advantages of the additive manufacture in the production of complex geometries?

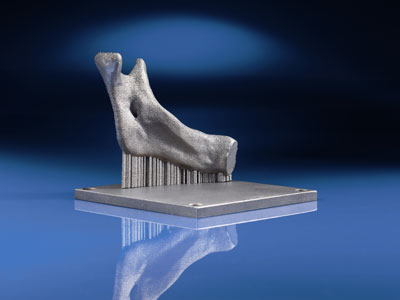

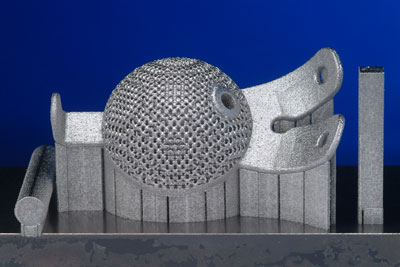

The main advantage of the processes of formation of layers is that they allow to produce any imaginable form that can be created in a 3D CAD program. There are no restrictions in terms of manufacture of transparent or hollow structures. Neither the geometries and free designs are an issue.

At first, the additive manufacturing was reserved to the implementation of models and prototypes, what are the practical applications in mass production?

We are only at the early stage of development. New and improved materials, as well as a more stable processes being developed. However, are already seeing the first best applications in implants, dental technology, and in light of automation components. In these fields the individualized series production is under way in almost all aspects. We are also seeing new applications in the manufacture of aircraft, where the light metal construction with Titanium is beginning to play a particularly important role.

Is there a limit on the freedom of creative design? Are they going to be obsolete the traditional patterns of design?

The fast and direct manufacturing through additive processes, thanks to its almost unlimited freedom for the form and design, allows you to create optimal and customized products. Due to the geometric freedom and high elasticity of the material, it is possible to make connections to pressure, elements of lock with complex forms, connections and geometries with spring as baleen or coil springs. This means there are fewer pieces to be mounted or connect with tools. It is the first thing they have to learn the engineers.

What believed to be the main categories of additive manufacturing application: medical technology, mechanical engineering, the construction of tools and dies, the aerospace sector?

All are areas of interest. We do not make distinctions by sectors, but by applications. In all of them it is possible to achieve a series production and individual parts and components specialized at affordable prices.

Is there any difference with regard to target groups in Microsystems Engineering and the manufacture of dies, for example?

Yes, simply because the requirements for the engineering and materials used for this are completely different. The technologies used here are also quite different. It is important to not introduce additive manufacturing techniques in all parts, you must first understand exactly what they need customers. This will also allow the penetration of additional markets such as biotechnology.

Between several existing methods for additive manufacturing, which does better opportunities in the long term to be adopted in the general terms for the industry?

It should one not be compared directly the different technologies. We must choose the appropriate technology depending on the particular application that is planning. This is an important aspect for newcomers: the first implementation, then the technology. Today, laser systems are being used especially in the field of the production of final pieces. In the future, systems of printing technology to be used more and more, especially in Microsystems Engineering and biotechnology, where in the next 3 - 5 years will occur many things.

Currently, what role plays the additive manufacturing chains of automated processes?

Still none. Although the integration of new methods of manufacturing in the chains of industrial processes provide powerful options to optimize the operations of production, due to the lack of organization and autonomous machines still there has been little in terms of the implementation. As batches have a minimum size and the Assembly thanks to the complete manufacturing processes have been eliminated, there is concomitant potential for achieving greater effectiveness, although to do so, of course, it is necessary to receive the support of the correct Organization. Additive manufacturing allows to solve certain problems in the conventional structures of production, although it is becoming quite difficult to integrate these systems into the matrix triangular time/cost/quality due to the lack of comprehensive production models.

Tell me the reproduction capacity of involved processes and the assurance of quality in mass production? Is there some method of reliable simulation?

The ability of reproduction of the processes involved is the main focus of the work that is underway and is something that must be achieved in the coming years. The issue of quality is addressed in the guideline VDI 3405, entitled 'Additive manufacturing processes'. Numerous research projects, as well as internal development by OEMs, who then dealt with this issue are currently being conducted.