Interview to Oliver Stammen, boss of sales in Thielenhaus Technologies

In the current was of the miniaturisation every time gives more to perfection geometrical importance in the components. Like specialist in finishing, no only has to concern by the topography of the surfaces, but also by the geometrical forms. Which problems pose nowadays to the hour to fulfil the exigencias?

Generally, the difficulties root in the exigencias geometrical indicated in the outlines and in the margins of tolerance, that every time are lower. If, by means of his current process, the attendants do not attain to keep inside the margin of deviation allowed, will have to look for an alternative process or a form to optimise the already existent process.

On economic grounds, the small companies are decanting by an optimisation of the process before that by a new investment. In this sense, are not entering in a much more complex terrain?

In reality, yes. Thus, first they would have to analyse the necessary effort to adapt his traditional processes to the exigencias. Between other things, have to consider the qualification of the operarios to charge of the machines, the costs of the necessary tools to fulfil the degree of exigencia higher, the extension of the cycles of work, the increase of resources for the control of quality and, in occasions, also the cycles of adjust and a greater tax of defectuosidad. Finally, has to guarantee the capacity of reproduction of the same conditions in all the batch of components. The existent processes can force , but always inside some limits.

Inside these limits, is not more reasonable to expand the chain of processes with an operation more than mechanised?

In principle, the company has to check if the material that it has is very employed. In this sense, has to have in consideration that the exigencias of quality do not go to collapse en el futuro, but they will follow increasing and will go arising criteria of additional assessment, as for example the analysis of Fourier. Of course, an additional operation also increases the unitary costs and, often, the results of this investment can not evaluate in base to an alone request, especially in the cases of companies providers.

Which believes you that is the solution to this problem?

When it exists the danger that an existent process carry further of the limits, has to descartar like main aim the extension of the chain of processes with a special machine. In this case, the first that has to try is a combination of methods. In the simplest case, this will consist in the integration of a machine of Microfinish in the machine-tool already available. If this was not possible, is more profitable to invest in a machine of flexible finishing and that incorporate the most modern technology, that can configure of simple form for the exert of other tasks. For example, we have developed modular systems that the own attendant can adapt for the realisation of other tasks by means of the connection or disconnection of the modules. In this way, it makes possible the combination of processes. Besides, since the reuse of these machines in the market is considerably greater because of his flexibility, also enjoy of a better assessment between the banks of credit, which carries to some costs of financials lower in comparison with the special machines.

Which problems related with the geometry affect to the companies in the practice?

Ours machines use with more frequency to achieve improvements in the planicidad during the straightened; in the circularidad of the components ondulados and cylindrical, as well as of the spheres and sockets, and in the rectitud, for example, of the ways of rodadura of the threads.

Which novelties contributes the method of Microfinish?

This method, that carries testing his efficiency already from does decades and that even nowadays follows evolving, guarantees the highest geometrical precision and the dimensional tolerances more adjusted in the time of mechanised more reduced, so that the usual effort of classification and pairing can delete. We speak, in this case, of geometrical efficiency. According to our needs and the parameters that enter, the method of Microfinish guarantees uniform finishings that, often, rondan a value Ra of 0,05 <#comment>µm And surfaces of contact with a Rmr until 99,99%. Because of the low temperature of work, the superficial structure of the peripheral zones is, after the mechanised, considerably more resistant that before. In this way, by means of the creation of flat structures, can influence of direct form, for example, in the properties of friction and important slide in the plane of the energetic efficiency.

A group of researchers fineses and Americans of the car sector has calculated, for example, that so only a fifth of each litre of fuel allocates to the propulsion of the vehicle. The rest loses in shape of heat and friction in the engine, until 35%, and in the gears, until 15%. In the future, with the aim to avoid these losses, surely will reduce of drastic form the margins of tolerance of the corresponding components, which will do that the finishing of surfaces take a big importance. In the other sectors, the measures that implant in relation with the energetic efficiency also will end in a greater degree of requirement regarding the pieces of work.

Has this method some advantage more?

Yes, since all the methods of mechanised conventional have limits that give like result a deviation of the optimum mathematical form. These limits delete largely with the use of Microfinish, because this method superimposes the movements of the mechanised. When achieving the elder solapamiento of tool and piece of possible work, can, for example, delete the deformation in the cojinetes of an axis. Besides, also they do possible logarithmic profiles and superficial structures of big complexity. Because of the mechanised, also increase considerably the tensions of positive own compressesion in the surface, so that this goes back more resistant. The components can, in this way, do smaller at the same time that keep the same resistance. This and the minimisation of the values of friction are the key factors for the energetic efficiency that so much boosts in all the senses nowadays.

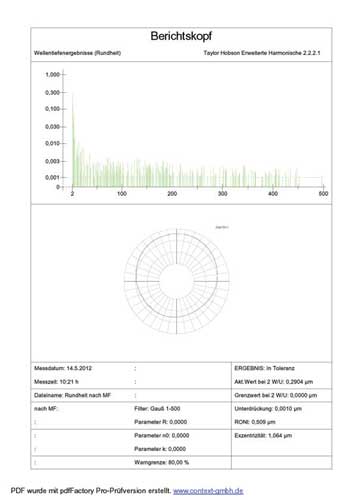

Besides, our method achieves to minimise the noises, delete them and even adapt them according to the needs. These exigencias multiply over time, and no only regarding the pieces of the gears and the pieces of steering. The noises originate by the vibrations and, in base to an analysis of Fourier, can delete the vibrations in the most complex areas by means of a mechanised direct of the same. In this sense, what less divert a component of his optimum geometrical form, better will be the value of vibration.

Or, for example, a surface can need shine especular to use it like base for circuits integrated printed matter, that is to say, that the piece of work turns into a plate. Even they can use these shines especulares or marks of micromecanizado voluntary to create interesting effects and improve the so important design in the products of high quality.

Go back to the subject of the vibrations, since no only originate noise but, besides, because of the interferences that cause, can have a negative effect in the useful life of the isolated component or of all the group. Illustrate us with an example of the differences in this sense between the method of mechanised with Microfinish and a conventional method.

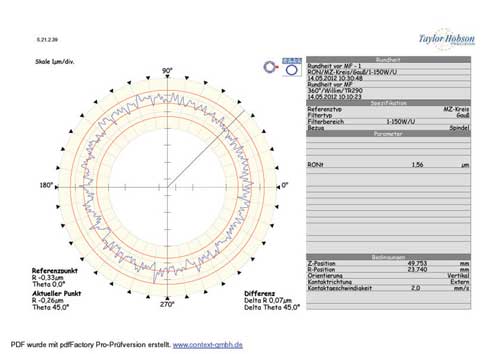

Put, for example, a piece ondulada with cojinete like an axis in a gear: in principle, a cylinder with a clear-cut fall in the edges. The piece of work presents often a hardness of aprox. 58 HRC. The methods of mechanised typical for the cojinete are the turning and the rectified. During the turning, produces a contact more or less puntiforme between the blade and the piece of work, whereas during the rectified this contact is linear. In both methods, so only is possible a solapamiento of the very low tool. The advantage is a volume of shavings very high; however, also it exists the inconvenient that the small vibrations mark on the surface of the piece of work and deform it. Now, these vibrations can counter integrating guides with atenuadores, big measures in the bancada of the machine and cojinetes hydrostatic when building the machine, which, of course, puts up the price of it considerably. In this way, it achieves that the vibrations adjust to some margins of lower tolerance, although they do not delete completely. After all, the vibrations also originate in the own piece of work, that has his own answer of resonance.

In the most extreme cases, form marks of vibration?

Yes, in these cases, speak of vibrations with a high amplitude. However, also the vibrations of low amplitude, that is to say, with breasts of dimensions micro or nanométricas, exert a paper in the production of noise and the useful life of the component mechanised. Therefore, if it glides a rolling of needles by the surface of the cylinder, the needle establishes a linear contact with the ondulación. This accelerates during the filmed of the cojinete of radial form. Said acceleration, that can be of variable intensity, produces so many noises like a greater wear. In the processes of linear contact or puntiforme, this can not avoid.

How can avoid this problem?

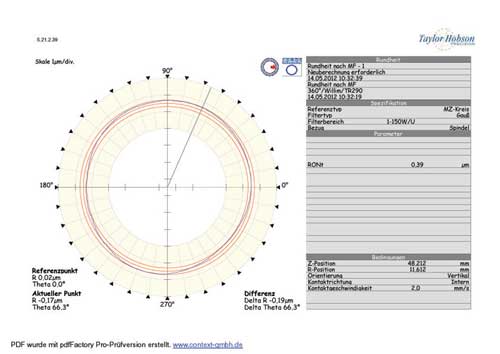

If it selects a tool that establishes a wide superficial contact regarding the piece of work, like the pressesure of a semicoquilla on the cojinete, the vibrations can not mark in shape of ondulaciones or achieves delete the already existent deformation, because, in principle, with the semicoquilla only aplanan the crests of the ondulaciones. In the method of Microfinish, the tool oscillates in addition to axial form. Thanks to the solapamiento of these movements and in combination with the rotation of the piece of work, force a micro and macrogeometrías very high. In this sense, use tools of strip with plates of compressesion or tools of stone adjusted with distinct unions and punchers according to the needs.

What resulted can reach ?

The results depend, of course, of the quality of the premecanizado. However, can achieve geometrical irregularities, for example, regarding circularidad and cylindrical form, of less than 1 µm. To this adds the analysis of Fourier and, like result, influences of positive form in the broadcast of noise. All this can show it with pieces of work in real machines to the interested in this method and document it with the corresponding measurements. Besides, can create you show limit for all the pieces of work, by means of which check until which point improve the existent processes and optimise his costs, without influencing negatively in the final result.