The profession turns into passion by the work in LAEF

In fact, in LAEF work with Intermaher from 1985, when they bought them the first Mazak. At present it has 12 machines of the Japanese manufacturer, the last of them purchased in January of 2012 “to be able to export. We have had to us adapt for the export, because it is what sues now the market”. It is a ready machine to mechanise any type of complex piece, like the nuts of the husillos of the machines of numerical control, in this case in scoop for Shuton.

Like this, carry already 12 years of relation, professional and of friendship, with Intermaher and Mazak, and with Integrex so much for turning like mechanised.

A turn by his workshop us adentra in a company with up to date technology, with a capacity of excellent production and that it can give answer to the demand of the most miscellaneous pieces. It is the case of the elements for space structures, spheres and disks more specifically, that companies like Aceralia, Asteca or Lanik have commissioned him. In the first case, for the structure of the hangar of AENA in the Airport of Barcelona, the shopping centre Marinedacity in A Coruña and the project of the stadium of football Sand of Pernambuco, in Brazil, between other others. They are pieces where LAEF has been able to apply his ‘know-how' in mechanised, his experience, because there are cases in that they have to investigate, in front of a new challenge, how face that piece, “how mechanise it with the lower tied possible to reduce his cost of production to the maximum without renouncing to the quality”.

Because Martín has it very clear “a company that want to be in the peak, nowadays can not be more than 2-3 years without innovar neither buy new machinery”.

A man with vision and value

Bought his first machine with little more than 200.000 pesetas, of the compensation of the German company Kasto. “Of them I learnt to work of a way that seemed me very correct and applied it in my company”, affirms Martín. Then it was boss of workshop, with 28 years. It ran the year 1978 and that was his first numerical control. “When the competition, that said that it would not have sufficient work to be able to it pay, began to buy machines CN, I already had 3”.

His success has to , partly, to the value and to the vision of future, such as it defines it Roberto Hernando, of Intermaher: “In Spain there is the one who lives regretting of the bad luck, speaking of what could do but without doing it. It is necessary to have arrests and instrument with technology to differentiate of the competition and offer value. Martín is like this. It looks for the profitability, clear, if no, there is not business, but knows that this attains with technology. Therefore it has been pioneering in Saragossa. Because it has vision and value”.

In LAEF can find lathes fresadores from 9 axles, machining centres of 5 axles, machines of last generation, etc. “that, by his productivity, do not result expensive. It is necessary to know combine costs, robustness and productivity”. For Martín, this technology allows them work for markets advanced.

Integrex 200-IV, the last in incorporating to the family

With her attain to realise, in a tied, what with others would do with several tied and, besides, with the minimum intervention of the operario, explains us the soul mater of the company. “This technology is the one who provides us the maximum productivity and reliability so that our products can satisfy entirely the exigencisa and needs of our customers, so much in quality as in price”.

This machine allows to do unitary pieces, with specific planes for each one of them. Pieces that are fundamental for the good operation of the machines of numerical control, so it was vital to have a machine of maximum guarantees. “Because what less touch the piece, better” —adds Roberto Hernando—.

This constant renewal has supposed them also a permanent learning. “And in reality it is also an advantage for the operarios, that recycle continuously, also regarding the hygiene. The systems of hygiene that integrate these machines do not have already at all that see with the conventional. An operario no longer touches the piece until the machine is entirely unemployed, what supposes a plus for them also because the work realises it the machine and the operario only supervises it”, affirms Martín.

Work with machines advanced from 1978 has done that the evolution was almost natural, without traumas. There was not a sudden jump of the traditional machines to the numerical controls. All adapted little by little, he and his operarios, reaching a quality of work that Martín stands out especially when it speaks of the workers of the company: "they Are a value in the company and carry so many years with us that are almost splits of the family”.

LAEF – Mazak, a history of love that comes of far

“Bought the first Mazak, secondhand, in Madrid. It was when I gave me account of the advantages of this mark, and one of them is the team that there is behind. And Intermaher has done a big effort regarding the technical service. Never I have felt me neglected, so here I follow, with machines Mazak and with Intermaher. And I follow faithful to my lemma: German car and Japanese machine”.

Adapt or die

In LAEF have done good this maximum. In 2004-2005 70% of his production was for a concrete customer. But conscious that “had to adapt us to satisfy other markets” bet by the diversification. Nowadays they work for machine-tool, oil industry, agricultural, construction, public work, etc. “almost all the sectors less the industry armamentística”, being able to manufacture long series of pieces —whose production in the last years has moved mostly to emergent countries— to short series and pieces of big complexity, by what “need the best technology and workers very qualified”.

Variaxis 730-5X, “the more in technology in centre of mechanised”

“knew It in a trip that Intermaher organised in Mazak, Japan, and me enamoró so much that when going back bought it. To the six months, purchased a second unit”.

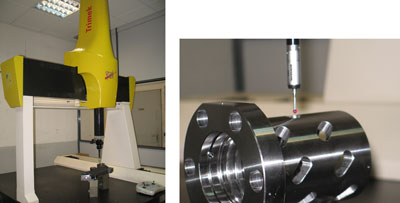

Control of quality

Work for demanding companies, of high quality, demands to guarantee also the highest quality of the pieces supplied. Thus, in LAEF realise controls of exhaustive quality, accompanying the pieces of his corresponding dimensional certificates, well on one of each ten pieces manufactured, roughly, or, "in those occasions in that the customers ask it to us, in all they, that besides label properly”.