The productivity and the energetic efficiency like promoters of the innovation

16 May 2012

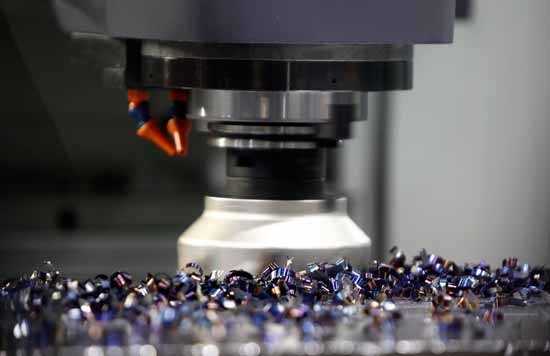

Nevertheless, the mechanised complete keeps on being the focus of attention, independently of the field of application. The new machining centres no only allow the turning, milling and taladrado, but now they facilitate even the rectified and ahuecado. From the side of the tool also carry out several operations of mechanised with an alone tool, for example, when it treats of the taladrado. But the subject of the energetic saving no only finds in the centre of attention in what to the pieces refers . Regarding the design of the machines, also are realising big efforts to go diminishing constantly the consumption of power. Examples of this are the recovery of the power of brake of the husillo and the effective employment of secondary groups oriented to the needs.

The energetic efficiency of the machines-tool keeps in the focus of attention

The energetic efficiency of the machines is, especially in the industry of the car, an important criterion to take a decision of purchase. Therefore, it treats of a commercial argument very important for the manufacturers of machine-tool. In this sense, offer a big potential of saving the hydraulics groups that require , for example, for the technician of subjection and accionamiento. These components work already many times on an electromechanical base. The accionamientos with possibility of recovery and accommodations of friction reduced are other starting points for the reduction of the needs of power.

Also are taking measured to increase the energetic efficiency in the formative field, where use machines-conventional tool for didactic ends.

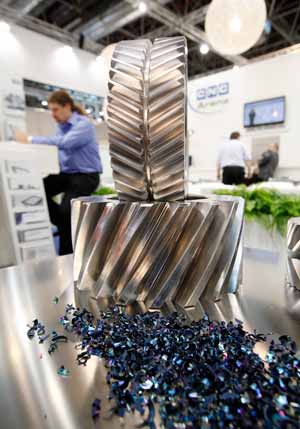

Increase of the productivity

With the end to increase the productivity, the manufacturers encourage for achieving that they realise in an alone machine all the steps of mechanised until achieving the component finished. The new machining centres allow the taladrado, milling, rectified and ahuecado in an alone subjection. In addition to the procedure of taladrado standard, the new tools allow the classical procedure of taladrado deep with expulsor in an alone subjection. In this way it is possible to produce complex structures as, for example, trains of landing. Example of this is the new taladro for deep holes that, to his time, has of a unit of turning. This unit of turning allows the taladrado deep and the turning in a same subjection.

In addition to the mechanised complete, the efficiency of the machines to increase the productivity has the maximum priority. The production neglected, realised by means of the corresponding software CAD/CAM, has a high demand like consequence of the increase of the costs salariales. In this sense, can find already in the market machining centres horizontal that can operate practically without human intervention thanks to the software that incorporate, in standard versions of two palés that, optionally, can increase until six and that they can use like centre of mechanised of 5 axles, lathe or automatic lathe.

Start of shaving weighed and of big pieces for the energetic technology

The energetic technology is a market in growth in what to the construction of machines tool refers . So much in the sector offshore as also in the construction of electrical head offices are building new installations and more efficient. The necessary components, for example, for the wind installations suppose already a big challenge only by his dimensions. In this sense, the Basque company Goratu Machine-Herramieta offers milling machines of mobile column that allow visited of trip of 15.000 x 1.500 x 3.000 millimetres. With a precision of positioning of 0,01 millimetres on a length of 4 metres can realise mechanised of high precision.

New concepts for the supervision of the process

Guarantee the hygiene during the process of mechanised, that is to say, can mechanise the components of stable form and with a high quality, is one of the main aims of the manufacturers of machines. For this applies , for example, the concept of the airbag of the car to a machine tool. To such end uses a technician of sensors of acceleration in 3D to detect critical situations for the machine and can react immediately in front of them.

In concrete applications attract the swings of the husillo portapiezas during the milling of desbaste. The information registered provides to the operario of the machine indications for the programming. In the control can define until three limits. The first limit describes the increase of the effort for the tool when the wear is excessive. The advance reduces . In case to exceed the second limit, the effort for a mechanised sure no longer is guaranteeed. In consequence, detains the program of the CN. If it exceeds the third limit, has produced a collision between the tool and the piece. In the normal service, the machine would try in question of milliseconds keep his speed, causing in this way deformations of the husillo main if the control does not have foreseen a surveillance of collision. Nevertheless, thanks to the catchment of the swings, with the sensor of acceleration desconecta the engine in 2 ms. Therefore, the system offers the possibility to define processes and warn damages in the machine in case of collisions.

New concepts of refrigeration like key for the success in the start of shaving of special materials

The start of shaving of special materials like alloys in base of nickel or titanium remains determined by the reduced thermal sensors conductivity of the materials because of high temperatures. With the end to be able to carry out the mechanised of profitable form, use alternatives to the lubricación conventional by flood based in the emulsion.

A concept that has resulted very hit in the past is the refrigeration of high pressesure with emulsions. For the reduction of the wear of tools result decisive the volume and the strategy of supply of the half refrigerante. For example, Iscar Germany offers a support with a small tube desplegable in sense to the sharp singing that has been conceived especially for this task of mechanised. This design allows an exit of emulsions very near to the point of employment. The support can work with a pressesure of refrigerante of between 10 and 300 bars. The small tube is interchangeable. Thanks to the form and the transversal sections of the abertura of exit of the nozzle, can vary of form very concrete the current of refrigerante and the cover of the sharp singing with this support.

In the machine install some suitable pumps for the application of the refrigeration of high pressesure. They are many the manufacturers of machines that are instrumenting his machines of standard form with pumps with a pressesure of refrigerante of 50 bars. For tasks of mechanised special can be very useful employ some greater pressesures. Recently it presented to the market a new helicoidal bomb of low capacity that results energetically very efficient thanks to the specific regulation of the frequency. The valve limitadora of pressesure of this bomb can be activated of variable form of such way that, in comparison with a conventional bomb, the need of power reduces in 53%, independently of the pressesure. The helicoidal bomb of low capacity presented is able to put to disposal some pressesures until 200 bars.

Another possibility of effective refrigeration for the start of shaving of special materials is the refrigeration criógena of the process with liquid nitrogen. In the living room Metav of Düsseldorf could see an integrated cheese cheese solution in the machine. In this sense, the machine is instrumented with a tank in which it stores the liquid nitrogen to a temperature of -196 °C. By means of some valves and isolated pipes to the empty drives the half refrigerante through the husillo in the enclosure of mechanised and until the tool, that is where the half supplies directly through the edge. In a cavity situated behind the sharp singing transfers the heat of process to the nitrogen. Through the aberturas in the tool, the volumes of nitrogen heated deliver in shape gaseous to the air acclimatise. Thanks to this principle is possible refrigerar the tool very near of the point of employment.

Improvements in the concepts of machine

The refrigeration criógena of the process with the end to reduce the wear of tools does not result adapted for all the tasks of mechanised of special materials. For example, the mechanised of fragile materials like ceramics supposes some big challenges for the user, no only regarding the wear of tools, but also in what to the quality of the components refers . The material shows in particular a low resistance in front of the expansion of the fissures. It is thus that the mechanised of finishing results extremely important.

Precisely, a manufacturer of machines has developed a procedure that avoids practically this question. ‘Laserturn' Is a turning supported by laser. By means of a laser heats and desolidifica the material directly delate of the sharp singing. In this way it can reduce the wear of tools and improve considerably the superficial quality. This concept that has been installed in a lathe, also can use for the temper by ray laser. In a back use can temper martensíticamente in this way the zones of the tree subjected to a lot of efforts (for example, seats of cojinete, docks of adjust, etc.) with the end to achieve a greater reduction of the wear. With this procedure can reach all the degrees of specific hardness of the materials.

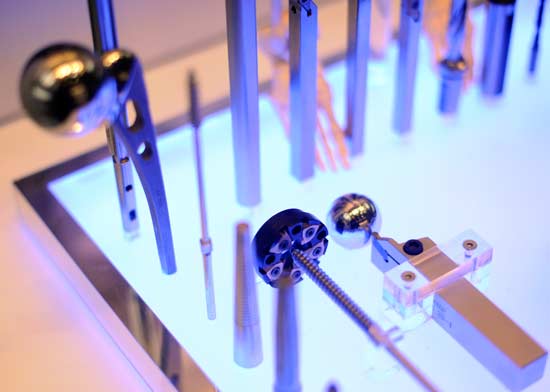

Tools perfected to increase the productivity

Also the tools go perfecting with the end to increase the efficiency of the concepts of mechanised existent. The tools of taladrado deep monolabial serve for the manufacture of able orifices to satisfy high exigencias of quality. Examples of application are the technology of injection in the industry of the car or the taladrado of trees of gears. The values of advance more reduced that they can achieve suppose a disadvantage in front of the broaches espirales. Thanks to the innovative versions of high speed is possible to compensate this disadvantage in his greater part. The rompevirutas with an angle of start of shaving very positive of more than 20° break better the shaving and reduce better the strengths of cutting. With the new broaches is possible to realise some advances between five and six greater times that with the tools of taladrado deep monolabial conventional

Under the name of ‘System Safe-Lock' exposed in the fair Metav (Düsseldorf) some tools of milling with protection against accidental extraction equipment equipment. The handle of the tool has of some helicoidal slots realised by means of rectified. Some arrastradores integrated cheese cheese in the seat of tool prevent, in case of the milling of high performance, that can extract the tool of his seat. To the greater hygiene of the process adds him an useful life the double of long and a productivity that of average is 30% elder.

So much the aeronautical sector component manufacturing sector component manufacturing like the energetic technology are markets of growth that by the materials of construction suppose new exigencias for the tools. The high thermal sensors resistance of the alloys to base of nickel like Inconel 718 favours his use like material for the construction of turbines. Nevertheless, a high thermal sensors resistance comports to the impairment of the characteristics of start of shaving, by what have to develop new tools. They exist already tools of taladrado adapted with a new coating that has been conceived especially for the problematic of the wear to the taladrar the material Inconel 718. This type of broca of ratio RT 100 HF reinforces especially the hygiene of the process and the productivity. The layer of signum also has been developed specifically for this application and is especially resistant to the thermal sensors wear and to the diffusion.

More ease for the management of tools

The management of the tools that use in the company supposes another approach for the offers that realise the manufacturers of tools and the specialists in the management of tools. In this sense, for a manufacturer of tools the flexibility of his systems of delivery of tools shows in a first plane. Like this, the system can expand of modular form and adapt without any problem to changes in the structures of production of the company. The delivery controls by means of a software. The system offers besides a big variety of possibilities of evaluation and report. Also it is possible to design this solution for several providers at the same time. In such a case it is possible to administer the warehouse for the means of comprobación, tools of setting and materials of consumption. Thanks to the integration on line of the system, the tools are permanently available, reducing at the same time the costs for the management of tools.

Reducing the variety of tools can reduce the management of the same. The manufacturers of tools offer, in this sense, solutions of milling that allow the use of plaquitas of specific reversible cutting in different tools of milling. For example, an active element that it can employ so much for flat milling cutters of less than 45° as also for inferior angles to 60°. These so versatile tools can use also for milling cutters of singings (90°) and milling cutters of high advance (15º).

‘Simply Coloured': Under this lemma a manufacturer of tools pretends to orient to the operario of the machine in the selection of tools. To such end, the tools, that in a first step are plaquitas of reversible cutting for the turning, are identified in yellow, red or blue in the orifice of subjection and in the sharp singing. The coding with colours of the orifice of subjection indicates the class of application in which it can classify the tool. The colour of the sharp singing defines the material of cutting of the that composes the tool. In this way it achieves limit a lot the danger of confusion when selecting the tool. Besides the employment of a sharp singing can detect inequívocadamente because of the desprendimiento of the coating of colour. A field of application for this simple but innovative concept is, for example, the industry of the car, where employ tools standardised.

Innovative means and principles of subjection

Thanks to the characteristics of the means of subjection, can influence directly on the efficiency of a process of start of shaving. The dishes of subjection of light construction of plastic of fibres by carbon allow to save between a 50 and 60% of weight with the same data of power and the same relations of strength. When being lower the mass, the husillo can accelerate more quickly, what to his time allows to shorten the times of production.

So that the process keep on being sure, is necessary to check the strength of subjection periodically. The new measurers of the strength of subjection transmit the data by Bluetooth to a computer of measurement. In this way it is possible to file of clear form the data in the production for any machine.

For the hygiene of the process, is important to attach well the broaches small. The new dishes of subjection hidroexpansibles of a manufacturer of tools for broaches with a diameter of between 2 and 5 millimetres allow the subjection of the tools of fast form, very exact and direct with a high strength of subjection. This type of subjection simplifies the manipulation and allows an adjust fast of the length. With an inferior value to 3 µm, the concentricidad is very precise even in dishes extralargos. The new dish of subjection is available for all the usual interfaces (HSK, SK, BT). The tools attached in the dishes of subjection hidroexpansibles can use with inner refrigeration or even with lubricación by minimum quantities.

Of conventional form attach the cylindrical components in dishes of three mordazas. Especially the tubes or the soft materials can suffer important deformations in case of high strengths of subjection. When the subjection realises go in more than three mordazas, the situation of subjection is excessive. As alternative, use dishes of six mordazas of compensation. These mordazas have been conceived of such way that, in each case, there is two mordazas forming a unit and are lodged of oscillating form. Of this form is possible to attach even sensitive components to the deformation or no round in lathes and lathing centres. This system can use for the inner and external subjection, and contributes some characteristics of concentricidad good.

Controls in the technician of modern production

The start of shaving in the process of modern production establishes some high exigencias for the controls of the machines. An important subject is the capacity of ‘multitaleatherg' of the controls that allows that they can carry out several tasks in parallel. The new 840D sl of Siemens AG, for example, can use for the turning, milling, taladrado, rectified and sawing. The aim of these concepts of ‘multitaleatherg' is the one to accelerate the processes in the production. Like this, the employees can use several machines without that require measured of learning.

Also the energetic efficiency previously described needs to carry out from the technician of the control. In this sense, the same manufacturer offers for his controls a combination of keys (‘Ctrl+And') with which the operario of the machine can access to the area of saving of power. In this menu can determine the use oriented in the need of the secondary groups.

Present all the range of products all over the world

A lot of companies have of a structure globalizada of customers, what involves some high exigencias regarding the availability of data. It treats , for example, to be able to visualise the archives CAD in any place without any problem. The software ‘Glovius' offers a new possibility. With this software can download from Internet the data CAD of form compressesed (only some kBits) using an iPad, what allows to represent without any problem and of spontaneous form the components in the installations of the customer. Therefore, to be able to present all the range of products all over the world, do not require the big volumes of data of the archives CAD conventional.

In the medical technician uses the CAM for the production with start of shaving, for example, of injertos. The aim is to generate automatically a program CN in base to a real component. For the concrete example of the medical technician, this involves that first it scans the articulation or the tooth that has suffered damages. Basing in the scan, generates a design CAD that to his time allows to calculate the track of the CN for the tracks of milling and rectified. These data transmit to a machine of 5 axles that commissions to realise the injerto corresponding. In the medical technician, the calculation of the data between the scan and the production has to realise of automatic form, since the operarios are people inexpertas in the mechanised.