Correct to save

December 14, 2010

With daily use, even the highest quality tool begins to show signs of wear sooner or later. For several years, Walter offers customers a comprehensive service of refurbishment to restore the worn out tools. "Solid carbide of high-tech tools have much value and are not something that you can buy every day," explains Michael Fink, Walter product manager. "Grinding and coating are, therefore, becoming increasingly important for many workers."

Original processes that lead to the original quality

The restoration is to be effective it is necessary to previously having some important data: with what Geometry produced tools? What was the process of coating used? These are issues that only the manufacturer can respond. So in addition to saving, customers also receive the quality that is given to Walter, reconditioning service restores tools and back them to their original state. The restoration and the production of the new tools and are used to exactly the same type of machine the same coating system. A key objective of the process of refurbishment is to restore the original performance of the tools without any compromise. For that reason, for example, the grinding takes place with the same CN program than the one used for the production for the first time the tool. In addition to using the same geometry, experts use identical carbides for coating for both new products and technologies. In this sense, the oldest tools also benefit from the latest innovations in the manufacture of tools. The continuous developments in the technology of coatings industry, for example, derived directly in the process of reconditioning. Michael Fink explains the following: "processes are absolutely identical." "The quality of the tools is equal to 100% in comparison with the new tools."

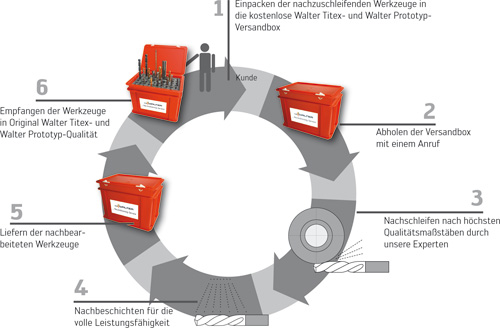

Standard tools returned to new State in ten days

Reconditioning service is backed by a concept of standardized and intelligent process from beginning to end, which requires a highly qualified staff and comprehensive expertise. A Messenger service collects tools worn directly from the client. They are transported in the "red box", a container especially designed to protect tools against damage. The tools are delivered to specialists in refurbishment of Walter that they have many years of experience in this field and know the detail the geometry of the tool and its coating. They have extensive knowledge of the machine and are able to prevent delivery delays. Once restored to his new State, the tools are returned to the operator through the messaging service. Customers can be assured that there are no additional costs for the packaging and transportation. "We have implemented many improvements in the processes that surround the refurbishment, both in production and in logistics service," adds Michael Fink that describes the continuing development of this offer of services. "This has helped us to achieve very short response times." "For example, covered with standard tools are restored to their new State and sent in ten days."

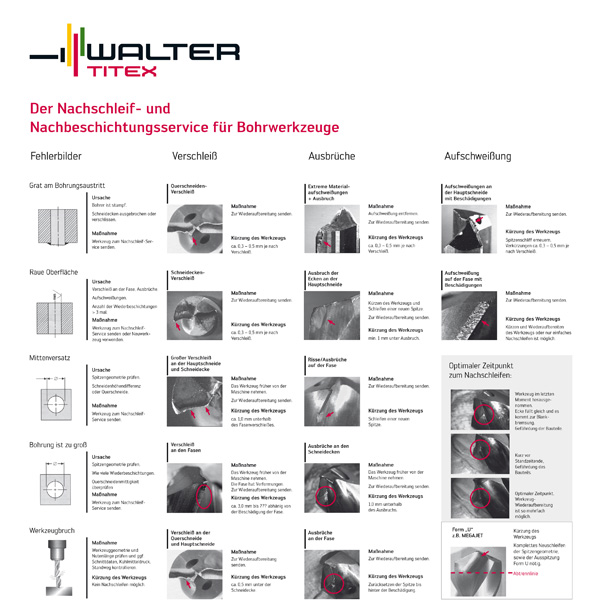

The wear patterns show the way

Wear on the side of the tooth, plastic deformation, recrecido Ridge and crater wear: the list of possible signs of wear on the tool is long and diverse. Among the various causes are, for example, a speed of cutting excessive or inadequate cooling. Correctly evaluate the State of a drill bit or worn Strawberry requires in-depth knowledge of the tool, as well as the application that is going to be used. With the help of special wear patterns and limits of wear, it is possible to determine the necessary corrective action. In this sense, the operator can see what must be done to ensure that the performance of the tool is the same as in the case of a new product and, in turn, customers benefit from important information on how to use the tools of Walter of a still more productively.

Grinding services reduce the costs of tool by 50 %

Refurbishment offers the operator a huge potential to reduce costs in the long term and increase productivity. Tools recover its original quality, with its price three times less than that of the new pieces. With third grinding, tool costs are reduced by 50%. To meet the growing demand of customers, Walter AG, with subsidiaries and distributors in over 40 countries, is expanding constantly its comprehensive refurbishment services both national and international levels. In addition to the headquarters in Germany, and other ten refurbishment centres had been established in non-domestic markets.

By the way, the refurbishment helps not only to the client, but also to the environment: companies save on valuable resources and produce less waste.