Without bactericides and bacterial growth cutting fluids

November 16, 2010

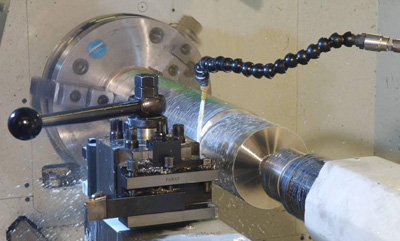

Henkel has managed to develop a reformulation of its patented, emulsifier technology successfully initiating a revolution in the development of the new generation cutting fluids. The new technology prevents the increase of bacteria by the absorption of nutrients from the degradation of the emulsifiers, once it has reached a minimum of bacterial concentration. In this way, Henkel cutting fluids comply fully with the directives of the EU on biocidal products. Surpassing the previous technologies, the formula of the new products Multan 71-2 and 77-4 completely prevents bacterial growth, which usually occurs with the use of cutting fluids, without using any antibacterial additive.

Water miscible cutting fluids conventional high bacterial exposure due to organic substances which contain commonly used in machining metals present. Due to this natural biological phenomenon, bacterial growth causes numerous technical problems in the production processes and creates risks for the health of employees. From a certain content in bacteria, a rupture of the cutting fluid emulsion is imminent. As a result, the emulsion may not continue using it and needs to be changed. In addition, bacterial metabolism leads to a reduction in the value of pH and increases the risks of corrosion. On the other hand, the uncontrolled growth of micro-organisms can be a threat to the health of the people.

Until now there were two ways to solve the problem of bacterial growth. In the case of court without bactericidal fluids, bacterial growth is tolerated to some degree. Only from a high bacteria content is introduced as a treatment for shock disinfection. This treatment reduces the number of bacteria and bacterial growth cycle is repeated. However, the disadvantage of this method is that employees are permanently exposed to the bacteria, bacterial metabolism products and high concentrations of biocides. This entails health risks for the staff. Eliminated germs provide an excellent medium nutrient for the next generation of germs, which makes it necessary to increase the frequency of the disinfections. In the case of cutting fluids containing bactericidal, bacterial growth is avoided when used properly. However, if the formula includes bactericides, employees have a high risk to their health when exposed to fluids of court.

Now, Henkel offers a solution to these problems with its new line of products that provide high performance without any additive bactericide. The new cutting fluids Multan avoid that employees are exposed to health risks arising from the presence of bacteria or bactericides, while benefits are maintained with a high quality. Currently, Henkel offers two products with the new technology:

- Multan 71-2, a multi-purpose product that, thanks to its power lubricant is suitable for heavy machining. It provides a fine dispersion so it is also capable of grinding.

- Multan 77-4, a product for the machining of highly alloyed steel and aluminum, the ideal specialist that provides high lubrication even at low concentrations.

On the other hand, it is noteworthy that with products Multan abide by the law revised on biocidal products in the EU which will enter into force in 2014 and will significantly limit the use of bactericides.