Solution of CNC B & R: the heart and the brain of the machine

October 8, 2010

Scientists are people who look beyond the usual responses and questions in this regard. Questions like "why machine tools should always build the same way?" Just because it is has done so for decades? "." This question was made by the team led the Professor Friedrich Bleicher industrial laboratory of the Institute of Industrial Technology and technology laser of high power of the University of technology of Vienna. "The laboratory solves specific problems faced by the industry through the scientific approach", explains the Mechatronics laboratory project manager Falko Puschitz. "This ranges from industrial technology and the production automated up to the design, construction and implementation of machine tools".

The customers are found in all branches of the industry in which conventional development methods are not able to solve the new problems that need a scientific approach. An example is a mechanism used when they drilled holes in great depth in very hard materials, which allows the detection and correction of the lateral movement of the drill.

New approaches for the manufacture of machinery

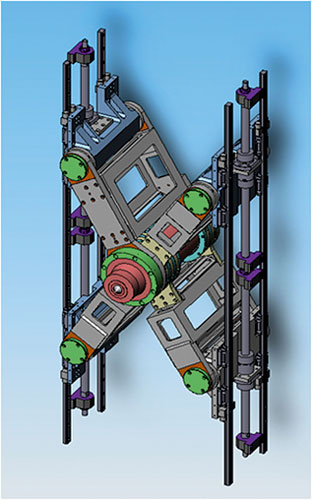

The search for new approaches to the production of machinery leads directly to the X-Cut, a machine whose main axis has complete freedom of movement on two axes to position itself in the space available. A third and a fourth potential axis can be added moving the tool head laterally regard the main shaft either by moving the piece to mechanise.

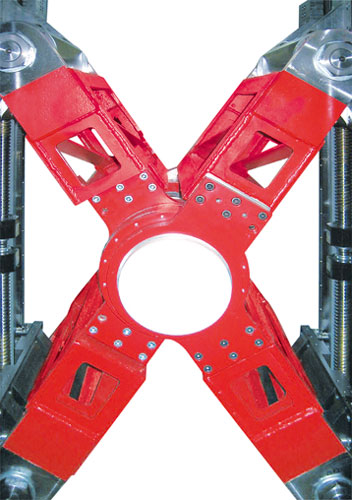

His name, X, comes from the high level of parallel kinematics, with two degrees of parallelism to the positioning of the main axis. The main axis is located at the apex of a triangle formed by two arms, with the ends move in parallel on a common guide in the opposite direction, moving in this way the main axis in the x direction and and. When this triangle is stretched to the limit (an angle or very blunt or very sharp), the arms become almost parallel - what scientists call it a singularity - and rigidity in one direction is lost. For this reason a second pair of arms is used to convert the triangle in a X (see image). In this way, at any point the weakness of a pair of arms is offset by the strength of the remaining pair.

This construction has four advantages over the conventional approach: on the one hand, thanks to vertical guidelines by which the arms are moving is achieved it the machine occupies less space in the soil of the area of production. On the other hand, the very construction of the machine gives you a much greater stability in the Z direction of the offered by conventional solutions. Third, the stability in the axis X and it can be directly controlled by moving the two triangles in a manner independently and adjust them to get an extreme stiffness. Finally, compared to machines based on a structure of Cartesian axes, the kinematics of translations of X-Cut allows accelerations approaching the 2 G by the low amount of mass to move, which also increases energy efficiency.

Before the question of why something similar not has been already invented long ago, Falko Puschitz offers a simple answer: "the Institute of Industrial Technology and technology laser of high power of Vienna has been working for years in the design of new machine tools"including test and development of special kinematic as parallel kinematics. The Quickstep and the Quickstep Neon are two structures tripods that have already been tabled at the EMO together with Krause & Mauser Machine Tools fair. "The sophisticated parallel structure of the X-Cut makes use of the extensive experience of the Institute to be a step ahead in relation to the conventional structures".

Control of the machine as a mathematical task

The control of the parallel kinematics of X-Cut is thus a task that goes beyond the sequential programming in a single move by steps. "More than schedule movements of the linear axes, is better to use the mathematical model of the inverse kinematics, and to use it also to all the necessary corrections" - explains Falko Puschitz-. "This is one of the reasons why we have decided to use the automation technology which offers B & R, because the B & R Automation Studio, development environment allows the programmer to develop these inverse kinematic". This seems trivial, but really it isn't: the majority of the traditional control hardware manufacturers, these functions must be programmed in the operating system. Thus, algorithms are usually already programmed in hardware by the manufacturer. "This would have been unacceptable for us" - says Puschitz - "because it would have not only delayed every step of the project, but also would have resulted that our knowledge would have passed to the manufacturer's drivers".

The production of complex components of individual form of the machine is expensive and public funding is limited, the equipment of the laboratory of technology of production of the University of technology Vienna, conducted simulations prior to the construction of the prototype. This applies to the construction of machinery, where it is necessary to test the distribution of forces under all possible scenarios of loads using finite element analysis. It also applies to the control in open-loop and closed loop, which tested using Matlab/Simulink before programming the machine. The new B & R Automation Studio Client tool for Simulink provides the possibility to generate a program code directly from the simulation model and then transfer it to the driver. "This saves us time and increases the security" recognizes Puschitz. "When there are changes, we can have the final program on the machine just a few minutes after having carried out a successful simulation." "And we do so without the potential introduction of new errors in the result of the simulation during the programming."

B & R automation technology

Another motivation for our decision to work with B & R was a completely integrated automation solution, informs Puschitz. "From the CPU to the engines, all control is common and the different teams are working perfectly integrated." "We do not have to worry about the internal communication between components, and also only have a contact person".

The power of calculation and management is provided directly by an APC 620. Due to the absence of fans and hard drive, it's a very flexible and robust industrial PC that connects to the X 20 modules via the rapid bus of Poerlink. X 20 modules are necessary to control machine (turn on the machine, change tools, enable the engine to the main axis, etc.). The machine has not yet mounted protection equipment of any kind, but when the time comes, it can be integrated using components Safe I/O series X 20 of B & R, which are programmed in the same development environment using SafeDesigner.

"The internal network of Powerlink has proven to be very effective in many ways" tells us Puschlitz. "Not only requires from very little cabling and limited amount of space in the Cabinet, but that can also handle a large amount of data, necessary to obtain a high dynamic and high parallel kinematics accuracy"", as well as for the diagnosis and management of the State of the positioning, which are sent by the same network".

Also connected to the CPU via Powerlink are the ACOPOSmulti servo. Powerful and compact, these servo provide maximum power in a minimum space. They are also equipped with intelligence, which provides an extensive list of possibilities for diagnosis and security without any type of external connection features.

The automation solution is fully integrated in the engines. The five Motors synchronous of B & R 8LS family, with a nominal pair of 31.6 Nm and a couple of blocking of 36.4 Nm, are designed for applications requiring excellent dynamic characteristics and high-precision positioningall in a compact size and low weight.

Vision of the future

Initially during its development, the machine was controlled with a B & R Automation Panel 900, but earlier this year B & R gave the University a preliminary version of CNC panel with a command of operation developed for machining centres. Equipped with functions of operation specifically designed for the CNC process, the control elements are customized for the project of example of CNC, but are also suitable for the application of visualization scheduled by the customer.

This ergonomic combination of panel operator equipped with numerous selectors of functions and buttons designed to operate in unfavorable environments - including by workers carrying gloves - is now available in the market after having been tested with success on real machine, as in the case of the X-Cut.

A machining center is not necessarily encapsulated in a Cartesian coordinate system axes. The Vienna University of technology provides a new approach that has resulted in the development of the X-Cut, a machine processing of three axes of high dynamic performance and that boasts an exceptional stability, high energy efficiency and compact dimensions. From the CPU to the engines, the sophisticated concept of control has been implemented using the technology of automation of B & R showing thus be appropriate for rare tasks.

Technological University of Vienna

The Vienna University of technology - T.U. Vienna - is one of the technical universities with greater success in Europe. With more than 20,000 students and nearly 2,000 researchers, it is the institution with greater technical research and educational and applied science of Austria.

The Institute of Industrial Technology of the technological University of Vienna covers a wide range of production and machine tool technology. In relation to the development of processes and related machines-related engineering, the Institute is regarded as one of more important in the research of production technology.