Advanced simulation to improve processes of castings

September 10, 2010

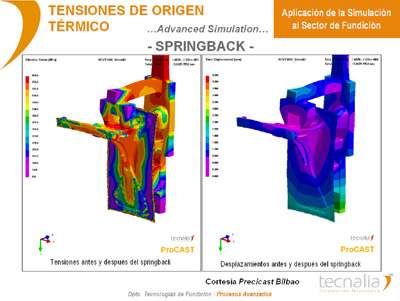

The advanced simulation, or perhaps we could call already as second generation simulation, we understand it as that, starting from conventional calculations of filling and cooling and solidification, arriving by applying new elements of calculus to the prediction of resulting metallurgical structures or to the growth of grainwith the possibility to conclude in the prediction of deformation, breaks or tensions generated in the final product.

These calculations require a growing knowledge of the properties of all the materials involved in the process, but today the actual physical values available mostly in literature and in the existing databases in this respectin spite of its precision (and the price that it is in most cases, should be añadir…) do not always return the expected results of simulation.

The need to pay off quickly and effectively these programmes, which are not cheap, and sometimes necessary databases 'ad hoc' force to quickly search for the profitability of them, which decreases subjectively as grows the experience in the use of them. This apparent contradiction is explained by the fact that industrial knowledge gained with their use is highlighting new needs expanding in fields not initially covered by the users.

Thus, privileged users, with more technical means and human than others at the service of that industrial knowledge, recouped it quickly and delve into the different utilities that provide programs, getting a revenue of exponential growth, because the knowledge of the tool involves a translation of this industrial process from a more scientific viewpoint that, as we say, opens up new areas of improvement and implementation.

Other common users, which for various reasons are only limited to 'push the button', also suffered many frustrations, when no rejections to a tool that itself is very powerful and absolutely useful. These numerous and perhaps slower, users can also be seen benefit for the 'second generation simulation', while on another scale different from the previous group.

The tool increases its value to become a true Bank, not only test but of technological capabilities and, as such, a tool for improving 'sensu stricto'. Only in the limit of the requirement for a given situation of technological knowledge these users might experience slowdowns in its advance into this knowledge. This slowdown is at the moment, when the simulation that we call second-generation may relieve them and involve them in a new phase of growth through knowledge of access to the next step, to new areas of study and the subsequent improvement.

So in a case in another, and although by different starting conditions, adjustment of process simulation leads to the knowledge of the same. So when we were saying that users could fall into a certain frustration at the fact that with 'perfect' geometries of the pieces to simulate, using with security program and calculating with the appropriate database, the results were not entirely satisfactory, or rather say as tight as they expect, we were referring to that, from this point of view, the calculation is performed in a quasi perfect, ideal situation, but that stubborn reality strives to demonstrate otherwise. Fortunately!

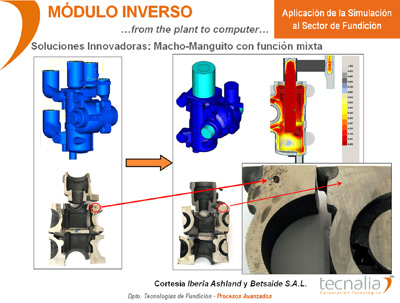

The smelter unit of Tecnalia has been more than 15 years working with the ProCAST tool which provides the reverse module and where adequately developed in conjunction with the application of criteria for foundry, based on the experience of the technicalallows characterize the materials for this purpose, get simulations 'tailor-made' for each user.

For more than 8 years, different virtual characterization projects have been carrying out, both in the basic components of the mold and some ancillary materials that may eventually form part of it.

Initially carried out projects into conventional molds that concluded with the edition of the complete electronic catalogue of sleeves and feeders of Iberia Ashland Casting Solutions. It was the first catalogue of this kind was in the market and allowing to simulate the exact behavior of these products, both insulating and exothermic. The values obtained not only were used by ProCAST and QuickCAST (before PamCAST), but that it was possible to extrapolate them to other programs on the market without compromising on the quality of results.

Now the work has been specializing into other types of moulds of high added value as, for example, in the area of the casting investment for aeronautical parts. In this sense, Tecnalia-smelting works closely with several companies in the aforementioned sector in various development projects, both fused components of recent improvement of its processes, some of them beyond our borders. In all of them reverse engineering has a crucial role and is the focus of the final result. As the projects are in progress, until the results, have not completed any information must remain anonymous for the moment.

In conclusion, to say that the virtual characterization of materials for use advanced simulation, by adjusted results facilitates the starting position optimal for the development of what we have defined as the second generation of simulation in Foundry. In addition, better knowledge of any of these materials brought about by the tool has allowed to extend benefits to other functions for which initially not planned.

Bibliography

- (2004) A. Meléndez, Anglada and et to the. ' New casting solutions: Numerically simulated EXACTCAST core-sleeve critical eliminate problems with automobile high-security components (patented)'. '66th World Foundry Congress' (6-9 September, Istanbul - Turkey).

- (2005) A. Meléndez, Anglada and et to the. ' Numerical Simulation of Exatcast core-sleeves for casting of critical safety parts'. Fonderie Fondeur D'Aujourd' hui, March 2005, N. 243, p. 13-22.

- (2006) A. Meléndez, Anglada and et to the. ' Improving casting performance through customized insulating shapes and advanced simulation techniques'. '67th World Foundry Congress' (5-7 June, Harrogate - United Kingdom).

- (2006) E. Anglada & a. Meléndez. ' Successful applications in castings using ProCAST Inverse Module'. ' EuroPAM. 16th European conference and exhibition on digital simulation for virtual engineering - Casting session' (10-12 October, Toulouse - France).

- (2008) E. Anglada & a. Meléndez. ' Quality standardization of big size castings for wind power turbines'. ' EuroPAM 2008. 17th European conference and exhibition on simulation-based Design - Casting session' (29-30 May, Prague - Czech Republic).

- (2008) Meléndez & Anglada e. 'Standardization of the quality of casting of large wind pieces by advanced manufacturing process simulation'. DYNA, may 2008, Vol. 83 N. 4.