A new visual environment to increase productivity

November 3, 2009

The announcement of the release of NX 7.0 was made during the annual meeting of users Siemens PLM Connection Europe which took place in Paris in October. "Our presentation of Synchronous Technology and their incorporation into NX earned high praise, not only of the majority of experts in CAD/CAM/CAE and industry analysts, but also companies that introduced her to increase his productivity in design"said Joan Hirsch, Vice President of Product Design Solutions, Siemens PLM Software. "The release of NX 7.0 is based on that the leadership of productivity with the incorporation of new significant features of Synchronous Technology, and the exciting introduction of HD3D, an innovative environment that will accept data from a variety of sources to establish a new standard for the Visual analysis of 'high definition' in the development of the product".

The need for visual information

Globalization and a growing regulatory environment, along with the increase in the sophistication of virtually all manufactured products, has created a complex process of product development for companies around the world. Hundreds of decisions should be made throughout the development of the product based on the information available in a variety of formats and locations, and in general, created by application software from multiple vendors. The speed and accuracy with which these decisions are made have a resounding effect on the success of a company. "Natural and efficiently to deal with these obstacles is to use visual information as a way to communicate through barriers and level the playing field for all participants," said Joe Barkai, Practice Director of Product Lifecycle Strategies for IDC Manufacturing Insights. "A collaborative decision-making process and assisted visually tools to support are essential for rapid, informed and effective decisions." "The use of these tools will facilitate better communication and understanding, and increase the loyalty of the decisions in the enterprise".

A new paradigm of visual analytics

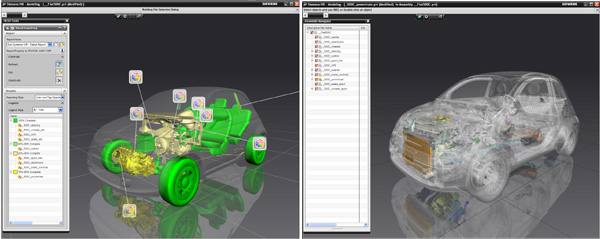

The introduction of HD3D in NX 7.0 is part of the global approach to the establishment of a new paradigm in visual analytics. HD3D is an environment to work with virtually any type of data PLM. This environment will be the same in NX and Teamcenter, the portfolio of Siemens PLM Software industry leading digital life-cycle management, and its open architecture will also allow the integration with several third-party applications.

HD3D extends the power of NX and Teamcenter to visually provide information businesses need to understand, collaborate and make decisions in today's environments of heterogeneous and distributed product development globally. It also provides a simple and intuitive way to collect, classify and present information in the product, and apply immediately in the critical decisions. HD3 in NX 7.0 implementation will allow users questioning visually and evaluate a product design based on any type of data in Teamcenter and NX, as the State of the market, controlled the weight thresholds, type of material, State of delivery, etc.

For example, a user of NX 7.0 could run a search report parts that are currently being developed and registered in real time or later. The NX 3D model of the product will visually highlight all parties that are in more than a week of delay and are cause for concern. Interactive labels are displayed on the screen and can be selected for more detailed information. With the potential of thousands of pieces in a specific product, this visual reaction and this interactive working environment eliminates the need for order through written billing materials and situation reports to interpret manually where the problems exist and what steps to take.

In addition to this visual analytics based on PLM data capacity, HD3D will be implemented within NX 7.0 'check-Mate', a check-up application based on standards that guarantee compliance with design criteria, consistency in the structure of the file in the CAD model and adhering to corporate standards and industry. HD3D will improve the tools of validation within 'check-Mate' with a new visual analysis user interface and delivery reports. Similar to the example above, the new environment improvement decision making during the validation of the product by providing an intuitive visualization of the results of 'chek-Mate' and evaluation issues.

Expansion of the power of Synchronous Technology

Ken Versprille, PLM Research Director of the industry analyst CPDA, refers to Synchronous Technology as "one of the most important and innovative technological advances in solid modeling in 3D of twenty years". NX 7.0 is based on its strong leadership position in flexible modeling and productivity with new improvements of Synchronous Technology to achieve improved efficiency, increased reuse of legacy data and interoperability extended with third-party CAD systems.

- Faster geometry creation and editing tools accelerate even more tasks associated with the creation and modification of designs. The intention of the design is applied and is housed in the time of the change and the reliable Edition eliminates update errors and long times of repetition.

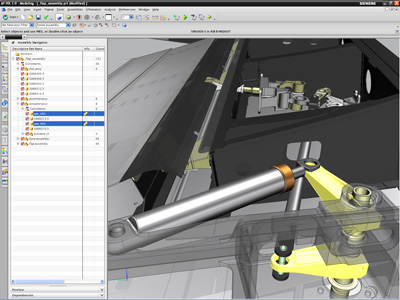

- The new powerful Synchronous design eliminates the need for original design intent when working with legacy CAD models and provides extended capabilities for cut, copy, paste, and reflect further improvement of productivity. This makes it easier to adapt the new designs of older models and saves time and costs through improved reuse of design data.

- New 'clean' tools editing faster and easier of models imported from third-party CAD systems. Automatic and semi-automatic mixture and the recognition of bevel builds and maintains relations for two of the most common features of manufacture, while options automatic and manual recording, along with the ability to combine segmented geometry eliminates unwanted separations, and sets not matching geometry.

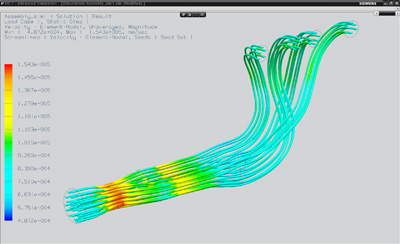

Synchronous Technology improvements in 7.0 have an impact on all aspects of CAD/CAM/CAE. In addition to its obvious effect on productivity for product designers, new functionality benefits from significant other members of the development team working with CAD data, including analysts and manufacturing engineers. These people mostly work with 3D models created by another person and often use a third-party CAD.

Synchronous Technology opens up a range of new opportunities for users of CAE and CAM to exploit directly the CAD geometry from any source. The easy to use on NX 7.0 interface allows users to easily modify the 3D models for your specific needs, enabling them to add value by focusing on their respective areas of knowledge. The combination of NX and Synhronous Technology provides a new paradigm of modeling throughout the product life cycle.

"We have replaced our NX 3D CAD system for their superior ability to offer an easy and flexible geometry noparamétrica manipulation", said Markus Pichler, Product Development Manager, BWT AG. "We believe in the greater capabilities of Synchronous Technology in NX 7.0, with its new geometric recording options, it will further expand our ability to quickly edit the CAD of legacy and third party data, creating a tremendous savings of time and further streamlining of our supply chain."