Light structural components for machines-efficient tool and of high productivity

J.J. Zulaika, J.To. Altamira And I. Oleaga, of the Industrial Division and of Transport of Tecnalia

J. Hernando, of Nicolás Correa S.A.

27/05/2014The reduction to the minimum of the mass of the machine allows to reduce the consumption of material resources in the phase of construction, and the consumption of energetic resources in the phase of use. The technologies that take part in this methodology cover from the conception of new architectures of machine until the development of new structural concepts combined with innovative materials, going through the integration of elements of active control of vibrations and accionamientos of low inertia.

1. Introduction

The ecoeficiencia of the operations of mechanised can measure in terms of relation between his productivity, measure in volume of shaving evacuated (Material Removal Rate-MRR in English), and his cost, so much economic like environingingmental [1]. Regarding the first part of this relation, the productivity of the operations of mechanised is used to to be limited in the big majority of the cases by the apparition of vibrations autoinducidas, especially for the case of vibrations by chatter regenerativo [2,3]. The apparition of this type of chatter comes defined by the following parameters: the material of the piece, the type of tool, the parameters of the operation of mechanised and the modal parameters of the system machine-piece [4]. These parameters are all they related with the operation of mechanised except the modal parameters of the machine, that for a concrete position, only can be modified if rediseña or modifies the machine. By all this, the machines-tool are used to to be sobredimensionadas, trying ensure that during the operative phase the machine will not see affected by the apparition of these vibrations. The problem resides in that this sobredimensionamiento goes against of the second factor of the ecoeficiencia, the economic and environingingmental costs, since a machine sobredimensionada affects so much to the costs of manufacture as to the ones of operation, to which it is necessary to add the environingingmental cost associated to the consumption of energetic and material resources [5].

By all this, the present work presents a methodology to design milling machines that reach an aim predetermined of productivity and that at the same time minimise the economic and environingingmental costs that are associated to his cycle of life, integrating of this way the concepts of productivity and ecoeficiencia.

2. Methodology for the design of machines-productive tool and ecoeficientes

2.1. Requirement of dynamic rigidity to ensure mechanised stable

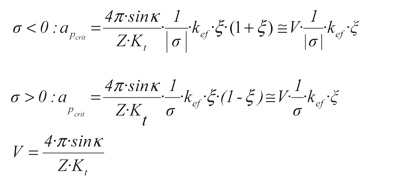

In [6] presents the resolution of a problem of own values of order ‘n' associated to the problem of stability of the operations of mechanised. In said resolution, obtains an equation that provides the relation between the frequency of chatter, the depth of cutting and the speed of cut, from which can determine the diagrams of lobules of stability and the diagrams of frequency of chatter:

- * Topcrit: critical Depth of past

- * κ: Angle of insertion of the tool

- * Z: Number of teeth of the tool

- * Kt: coefficient of tangential cutting of the material that goes to be mechanised

- * σ: steeringal Factor

- * kef: effective Rigidity in tip hta., kef =Ɯ2/{Φ}2; Ɯ=√(K/M), Φ= modal vector

- * ξ: coefficient of amortiguamiento

The equation (1) indicates that if it wants to obtain a determinate aim of depth of past –and therefore a determinate aim of productivity- for a concrete case of tool and material of piece, the product between the effective rigidity kef and the coefficient of amortiguamiento ξ of the way associated to the chatter will have to surpass a determinate value threshold, from the cual the mechanised will be stable.

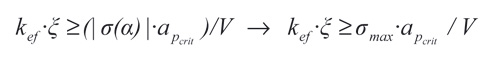

Of this way, if it considers the machine like a system of a degree of freedom with an effective rigidity associated kef, a coefficient of amortiguamiento associated ξ and a steeringal factor associated σ variable regarding the steering of mechanised α inside the plane of work,σ = σ(α), defining a new variable σmax like the maximum value in absolute value of the steeringal factor, σmax≥| σ(α) | ∀α, the aim of productivity translates to an aim of dynamic rigidity that follows the expressesion that shows in the equation (2).

Of this way, an aim of productivity for a concrete operation of mechanised and quantified in shape of an aim of a minimum depth of cut topcrit, demands that the factor kef ξ of the way limitante of the machine in front of chatter surpass a value threshold that depends so much of the operation of mechanised considered (factor V) as of the orientation of the way and the steering of mechanised (factor σmax).

Criteria of design to reach aim of dynamic rigidity with minimum mass

From the Equation (2), deduces that an aim of productivity determined can be achieved with a minimum of mass in the machine by means of two complementary approaches between himself:

- Reducing the value of the coefficient σmax by means of a variation of the orientation of the way, so that it can reduce the effective rigidity of the way kef in the same proportion at the same time that it keeps the objective value of topcrit. The usual is that in a design of machine there is little margin for modifications of design of calado, but is possible to achieve variations reseñables in the coefficient σmax with strategies so simple like changing the orientation of the cabezal or of the table of mechanised, such as it shows in the Figure 1. For the concrete case of the Figure, changes the relative orientation between the way to flexión of the ram in regard to the steering of mechanised, achieving of this way a reduction of 15% in the value of σmax without that have modified the mass of the machine, by what creates a margin to reduce the effective rigidity of the way in 15% -and by extension a reduction of the mass of the machine- without that said aligeramiento affect to the productivity of the machine.

- Optimising the relation between the factor kef ξ of the way and the mass that takes part in said way. For this option, are possible two sub-options:

2to. Rigidizar The way without increasing the mass of the structural components. A possibility is, for example, reinforce the system of guided in those ways in which the guided contribute a big fraction of power of deformation. Instead, if we find us with a way in which they are the structural components the elements that contribute the greater part of the power of deformation, a very effective approach is the one to replace the structural material by another of greater specific module.

2b. Increase the amortiguamiento modal without increasing the mass of the structural components. Like reference, the inertial actuators constitute a very efficient way to enter amortiguamiento structural in any mechanical system without that it take part a significant quantity of mass [7]. Another very efficient approach to increase the amortiguamiento modal, in this case for ways in which they take part systems of guided, is the one to enter guided redundantes in said systems [6].

3. Application to a fresadora of Nicolás Correa

Nicolás Correa has decided to apply this methodology for the design of milling machines productive and ecoeficientes to his line of milling machines Euro. It treats of a family of milling machines of fixed portico and mobile table and vertical ram, that offers capacities of desbaste and semiacabado and that is oriented to the sector of the general mechanics. The Figure 2 sample a fresadora of said family. Instrumented with an electromandrino of high speed, reaches speeds of advance of 30 m/min and accelerations of 3 m/s2.

Appears 2. Fresadora 'Euro' of Nicolás Correa.

The vertical ram has an approximate section of 350 x 400 mm2 and weighs some 370 kg. Like case of study for the methodology, goes to proceed to rediseñar this ram, since it is the structural component mobile of fixed weight bulkier. The table presents a greater mass, but the mobile weight total is tied to the variable weight of the piece that goes to mechanise.

3.1. Analytical and modal study of the fresadora of Correa

Like starting point for the rediseño of the ram of the machine Euro, has developed a model MEF that has allowed to obtain the own ways of the machine:

Way 1: Flexión lateral of the portico in the plane YZ.

- kef1 = 27.387 N/m; ξ1 = 1,1 %; (kefξ)1 = 301,25 N/m

- Way 2: Flexión frontal of the portico in the plane XZ.

- kef2 = 46.339 N/m; ξ2 = 1,2 %; (kefξ)2 = 556,07 N/m

- Way 3: Flexión frontal of the ram in the plane XZ.

- kef3 = 22.895 N/m; ξ3 = 2,7 %; (kefξ)3 = 618,16 N/m

- Way 4: Flexión lateral of the ram in the plane YZ.

- kef4 = 44.186 N/m; ξ4 = 1,2 %; (kefξ)4 = 530,23 N/m

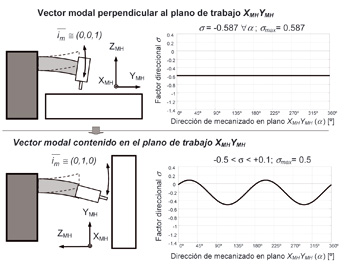

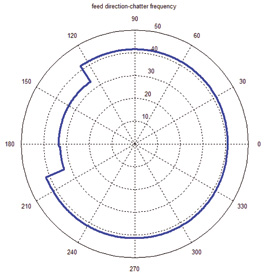

Said analytical study has been complemented with an experimental modal analysis, that has allowed to measure the real values of the own frequencies of the machine and especially, the real values of the coefficients of amortiguamiento modal. To continuation, if it considers for the study an operation of desbaste of steel F-114 with a dish of 125 mm, 9 edges of angle of position 45º and with a radial immersion of 80% in concordance, and considers that the rank of speeds of work of said tool finds in the rank of 400 to 600 rpm, obtains a polar diagram of critical depths of past such as it shows in the Figure 3.

From a process of identification of frequencies of chatter with structural frequencies of the machine, has arrived to the conclusion that the frequencies of chatter of said combination machine/process are associated to the ways 3 and 4 of flexión of the ram in the vertical planes XZ and YZ. Of this data can extract some conclusions of interest:

i) If it reduces the mass and the rigidity associated to said way and in parallel increases in the same proportion the amortiguamiento associated to said ways, will achieve keep the productivity of the machine with a lower employment of material resources and with a reduction of the energetic consumption in the phase of use

ii) If it reduces the mass and the rigidity associated to the ways no limitantes of the machine verifying at all times that said changes do not alter the character no limitante of said ways, will achieve keep the productivity of the machine with a lower employment of material resources and with a reduction of the energetic consumption in his use

From this analytical and experimental study of the Euro, have implemented the following changes of mechanical design to reduce the weight of the ram and at the same time keep and even increase the productivity of the machine:

1) Aligeramiento of the ram by means of a combination of reticular structures and light materials -> Reduction of the effective rigidity kef of the ways limitantes associated to the ram

2) Introduction of a system of amortiguamiento active in the ram lightened -> Increase of the amortiguamiento modal ξ of the ways limitantes associated to the ram

To continuation goes to proceed to explain in detail each one of these two strategies to lighten the ram and keep and even increase the productivity of the machine.

3.2. Aligeramiento Of the ram

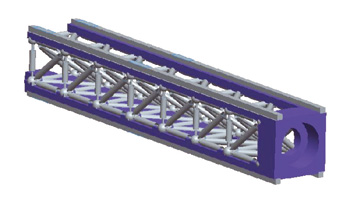

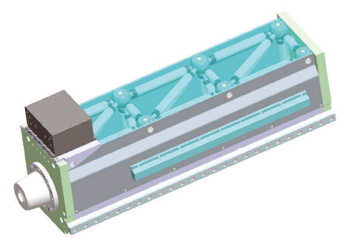

With the aim to reduce of radical way the weight of the ram and with restriction to keep the external dimensions of the same, has reconcebido of root his concept, employing a reticular structure and modulate, such as it shows in the Figure 4.

On said concept of modular and reticular structure, has gone optimising his design of detail in base to an iterative process in which they have taken part variable such as the material of the bars and knots, inner diameters and outsides of the bars, etc. The criterion that has followed is the one to reduce to the maximum the dynamic rigidity of the ram in the ways limitantes, that is to say, reduce the effective rigidities kef of the ways, and in parallel, increase the amortiguamiento of the ram employing an inertial actuator. Taking into account that an inertial actuator is able to cushion of around a 60-75% of the structural ways of a machine tool [8], has put like aim that the reduction of the effective rigidity was in said rank of the 60-75%. Of this way, the productivity that can reach the machine will not see affected in spite of that the rigidity of the ram –and therefore his mass- have been reduced of considerable way.

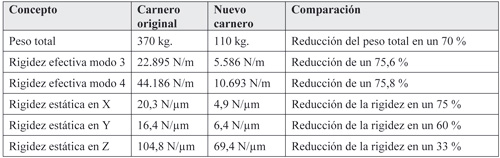

In this regard, the Table 1 sample of a way structured the main characteristic of the new version of the ram.

The Table 2, by his part, presents the main characteristics of the modular ram.

Once that it has designed the modular ram and lightened, to continuation goes to proceed to integrate in said ram an amortiguador active twinaxial, so that the conjoint effect of the ram and the amortiguador translate in a global maintenance of the productivity of the machine

3.3. Introduction of amortiguamiento active in the Demostrador

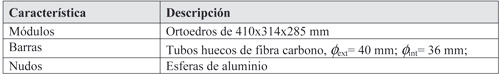

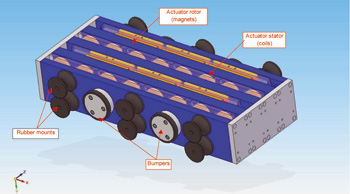

The Figure 5 sample an innovative concept of twinaxial inertial actuator that has been developed ad hoc for the present case by the Belgian company Micromega [9].

Appears 5. Amortiguador Inertial twinaxial developed by Micromega.

This amortiguador active twinaxial developed by Micromega has a maximum strength of 250 N, weighs 15 kg. And his external dimensions are of 250x150x120 mm. His maximum power is of only 250 watts, by what his effect on the global consumption of the machine is insignificant.

Once concluded so much the design of the ram as of the amortiguador active twinaxial, has proceeded to the design in detail of the group and his back launching to manufacture. The Figure 6 sample a global vision of the ram, where can see so much the amortiguador inertial -external to the profile of the ram- as the bars of tubes of fibre of carbon, properly protected by a transparent external plastic.

Once that the ram lightened and modulate was built and mounted, will proceed to integrate it in the machine ‘Euro' to be able to realizar experimental essays of validation, incidiendo of special way in the energetic consumption and in the productivity alcanzable with said ram.

4. Conclusions and perspectives of industrial exploitation

The present document has presented a methodology of design oriented to conceive milling machines in which aúnan a high productivity with a reduced environingingmental impact, appearance this related to a large extent with the consumption of material resources in the phase of construction and the energetic consumption in the phase of use. The approach has based in breaking the bond between a stable interaction machine-piece during the process of mechanised and the need to achieve high mechanical rigidities by means of structural components of big weight.

The design of a light ram and modulate inside a vision of a fresadora ecoeficiente and productive, in which it has achieved a reduction until 70% in his weight regarding the original ram, together with the integration of an amortiguador twinaxial has allowed to achieve an able final group to keep the original productivity of the fresadora in spite of the remarkable reduction in the weight of the ram.

All this carries to the conclusion that a multidisciplinary approach oriented to maximizar the relation between the mass involved in a machine tool and the productivity that reaches with said machine repercute of beneficial way so much to the provider of machines as to the user of the same, since by a part reduce the costs of manufacture and acquisition of the machines, and by another reduce also the costs of exploitation. In fact, this mutual profit, combined with a modular conception of the machines that allow a fast configuration of light and productive machines, can allow establish new models of business in the sector manufacturero between providers and users of machines tool.

5. Gratitudes

The authors of this work want to appreciate to the European Commission by the financials of the project ‘NMP-246020-2- DEMAT- Dematerialised Manufacturing Systems: To new way to design, build, use and sell European Machine Tools' inside the 7º Program Mark of Investigation and Technological Development, as well as to the Ministry of Science and Innovation by the financials of the project ‘Develop of an Intelligent System Hybrid to optimise the interaction machine-process in the productive processes oriented to the wind sector and of transport (FOEHN) CIT-020000-2009-12'.

References

[1] J. Zulaika, F.J. Campa, L.N. Lopez of Lacalle, “Light machine tools for productive machining”, 80 pp, ISBN 978-1-61324-644-3, Nova Publishers, New York, 2011

[2] J. Zulaika, F.J. Campa, J.To. Altamira, L.N. Lopez of Lacalle, G. Urbikain, “Using Stability Lobe Diagrams for the Redesign of to Machine-Tool based on Productivity and Ecoefficiency Criteria” 12th CIRP Conf. on Modelling of Machining Operations, Saint Sebastian, 2009

[3] J. Tlusty, M. Polacek, The stability of machine tool against self-excited vibrations in machining, International Research in Production Engineering (1963) 465–474.

[4] J. Zulaika, F.J. Campa, New Concepts for Structural Components, in: L.N. Lopez of Lacalle, To. Lamikiz (Eds.), Machine Tools for High Performance Machining, Springer Verlag, 2008, pp. 47-73.

[5] To. Dietmair, J. Zulaika, M. Sulitka, To. Bustillo and To. Verl, “Lifecycle Impact Reduction and Power Savings through Light Weight Echo-Design of Machine Tools”, 17th CIRP International Conference on LCE, Anhui, China, May 2010.

[6] J. Zulaika, F.J. Campa, L.N. Lopez of Lacalle, “An integrated process–machine approach for designing productive and lightweight milling machines”, International Journal of Machine Tools and Manufacture, Volume 51, Issues 7–8, July–August 2011, Pages 591-604, ISSN 0890-6955

[7] To. Ganguli, To. Deraemaeker, M. Horodinca, To. Preumont, 2005, “Activate damping of chatter in machine tools - demonstration with to 'hardware-in-the-loop' simulator”, Journal of Systems & Control Engineering 15: 359-369.

[8] L.N. López of Lacalle, To. Lamikiz, “Machine Tools for High Performance Machining”. ISBN: 978-1-84800-379-8. Springer-Verlag, London, 2010.

[9] www.micromega-dynamics.com