Technology for ‘shot peening'

Greater resistance to the tension, lower wear, greater useful life, and at the same time reduction of the weight of the piece. Because of these positive characteristics, the shot peening uses in several sectors of the industry, although it is especially popular in the aerospace industry and of the car. With his innovative technology of shot peening, Rösler no only offers more efficiency but also more hygiene.

Due to its modular design, the RSA 1400 model can be equipped with 6, 8, 10 or 12 rotating satellites. The load of satellites with parts is carried out in manual, semi-automatic or fully automatic with a positional tolerance of +/-1 mm.

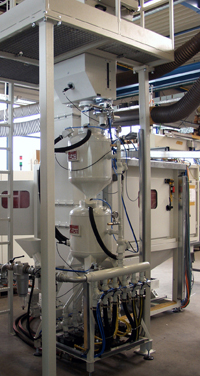

Rosler RSA 1400 model induces stress of compression with a high degree of consistency. The measurement of compressive stress induced always requires the destruction of treated components. For this reason the process parameters such as the angle of impact of the piece, blasting time, quantity and blasting pressure, should be kept within a small range. The desired result of shot peening can only be guaranteed with the precise control of these process parameters. Rosler RSA 1400 Sander features patented process and controls measurement that guarantee an absolute shot peening process repeatability. For example, the special shot dosing system ferrous and not ferrous emits a precise quantity of raw material dosing to spurt. Pressure and air flow are set and controlled with special valves. The hose connection is monitored to ensure that the abrasive reaches blasting nozzles in the quantity and correct pressure. Another important point is the constant control of the size and shape of the shot. The RSA 1400 machine is equipped with a fully automatic classification system of shot in 3 phases: during the first phase the dust and other small particles are removed with an air separator and a cyclone. The second phase consists of sieving of grit, which removes the grains out of size. The third and final phase consists of a separator to spiral, which eliminates broken shot and is not perfectly round.

Easy adaptation to a wide range of technological requirements thanks to their modular design

The RSA 1400 model offers not only a process of shot peening repetitive but also a high degree of flexibility. For example, the modular design of the rotary table allows the operation of the system with 6, 8, 10 or 12 stations rotating satellite. Depending on the parts to be treated, they can be directly mounted on the satellite stations, or, in certain cases, the satellites can be equipped with special attachments. The placement of parts on the satellites can be manual, semi-automatic or fully-automatic way with a tolerance of +/-1.0 mm. the loading/unloading area is completely separated from the blasting area to prevent splashes of shot in the cargo area and download. This design minimizes processing time, since the loading and unloading of parts takes place simultaneously with the shot peening process.

The system can be easily adapted for different quantities of parts processing.

The peening process is carried out with different nozzles blasting, which are aimed at the areas to be treated. In a time of 25 seconds process can be induced compressive stress levels up to 1,500 MPa on the surface of the parts. The system can be easily adapted to the process of different quantities of parts through the use of one, two or three seasons of blasting at the same time. Of course, depending on the parts to be treated, or desired results of peening, you can add blasting nozzles or stations of blasting.

For blasting operation interrupted, Rosler offers double pressure tank. A sensor at the bottom of the tank says when the abrasive reaches the minimum level. This causes the upper pressure tank to send abrasive to the lower tank. At that time, the upper tank is filled from the tank of shot blasting.

More safety and less wear using different cameras from shot blasting

Another important advantage of the system of blasting is the special design of the rotary table: the table is divided into several cabins of blasting separated by solid walls. Each cabin contains a work station to satellite, which allows the placement of one or more parts as for example gears. The machine can be charged and discharged manually or by means of robot. The cabins of Shotblast machines are built in manganese steel. The direct impact of the shot is additionally covered with hardened steel. Moreover, the cabins are equipped with special magnetic closures. All this ensures that the zone of blasting is sealed to protect the immediate environment. Therefore, there is no danger of that operator or the robot are achieved by shot-blasting, and the rotary table can index without any problem.

The GDR model is equipped with all kind of drivers that guarantee a process of shot peening with high repeatability and a high rating of the shot. It incorporates a blowing unit which ensures that parts out-free shot blasting residues on the surface.

This system allows compressive stress levels up to 1200 MPa.