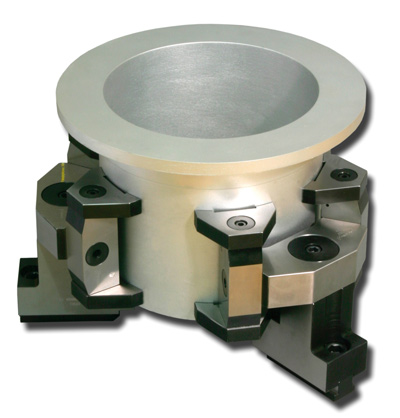

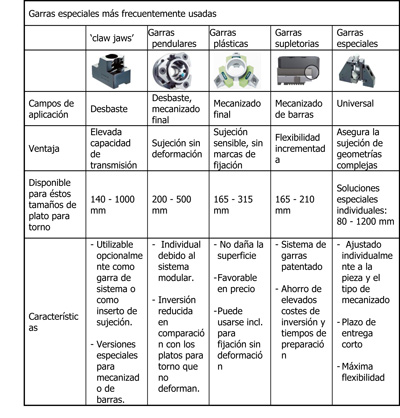

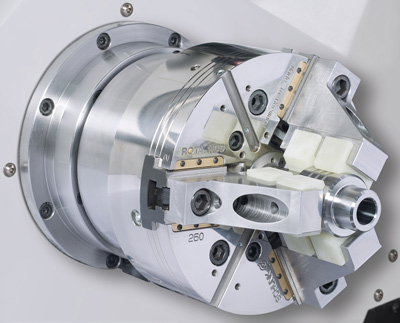

‘Claw jaws', the collaborators subestimadas

For the desbaste of pieces it is necessary to take into account the shavings that generate in little time. By what require strengths of subjection especially high so much for the turning as for the milling. The ‘claw jaws' offer in this field the best result. They are available for external subjection, inner and for the mechanised of material in bar. In contrast with the mordazas hard conventional, these hold more deeply in the surface of the piece, attaining like this adapt better to the form and a better subjection. Even with low strengths of subjection are able to transfer high pairs of rotation. The ‘claw jaws' of little weight work very eficientemente as they have of a special form of toothed, until three lines of toothed one on of the another. They allow advances very high and high speeds of cut with the end to minimise the wear, because they are toughened by cementation. By means of the use of topes standardised of different heights, the depths of subjection can adapt individually in each piece to work. A very economic alternative of the ‘claw jaws' monoblock, are the designated ‘claw jaws' universal. They are done of a mordaza in the rough no toughened, prepared with an angular strawberry and provista of insertos special of resistant carbide to the wear. On the other hand, it ensures an optimum contact with the piece by his slightly oscillating effect.

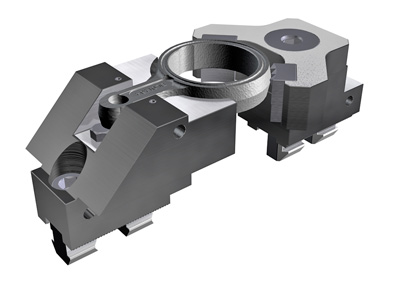

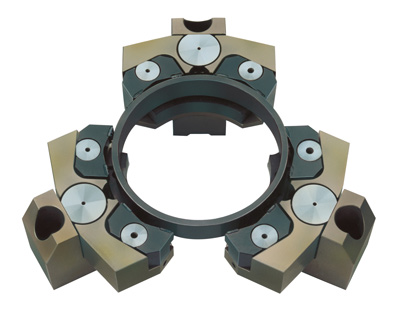

The harps pendulares attach of safe form and with little deformation

For pieces with walls of little thickness and with risk of deformation, require solutions to fix the components without deformation. If the user does not want to buy mordazas special of high price, can achieve the same effect with the harps pendulares standard more economic. The harps pendulares consist in a body pendular mobile with two insertos of subjection, that mount with a bolt of cojinete in a basic harp. They can instrument with insertos of soft subjection or toughened. Since they are mounted of the same way that the mordazas upper monoblock, can adapt quickly a conventional dish of 3 harps for the subjection by 6 points. The points of support that are distributed uniformly in angles of 60° in the circumferencia of the component or in the internal diameter, transfer the strength of subjection to six points of subjection and reduce considerably the deformations. If a tube done of aluminium, with an external diameter of 60 mm and an inner diameter of 50 mm, fixed with a strength of subjection of 100 kN in a dish of 3 conventional harps, the result calculated of deformation would be of 0,497 mm. The subjection with a harp pendular with 6 points of contact improves the value arriving to 0,029 mm, a factor around 17. By means of special programs of calculation, can determine in advance the effect of the harps pendulares. Since the mordazas adapt to the piece, can achieve a compensation inside a rank of geometrical tolerance, for example in a piece of ironinging. The most ideal would be that the harps pendulares use for the final finishing or in surfaces premecanizadas. With the end to allow high speeds, would have to be the lightest possible.

Harps of fibre of glass for fragile pieces

When require the subjection of an especially delicate piece and with little deformation, have the special harps done of fibre of glass and reinforced of plastic, like a ‘secret weapon'. Even in sharp pieces or with the surface treated, the harps of plastic do not leave marks. His high coefficient of friction of the 0,3 to 0,4, as well as his big angle of wrapping, guarantee that the high strengths of mechanised can transfer in low strengths of subjection. If a harp of plastic combines with a basic harp of aluminium, ensures an especially high stability. Because of the little weight of the basic harp of aluminium and to the of the upper harp of plastic, forms a low centrifuges strength during the turning. These sensitive solutions of subjection are adapted for high speeds of mechanised until 6.000 rpm and besides the insertos of interchangeable subjection are of a very alluring cost.

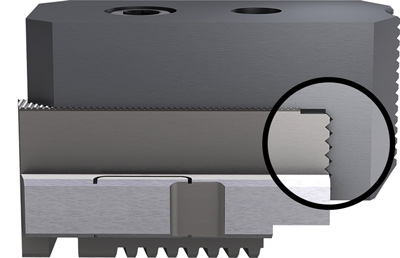

Intermediate harps for distinct interfaces

In the last years, numerous developments in the field of the dishes for lathe and the harps have carried to an enormous variety of solutions. Visible indicators are the interfaces estándard; “toothed fine” and “chaveta in cross”, which have different measures of connection. To be able to optimise the variety of interfaces between the dishes of lathe and the mordazas, developed the intermediate harps.

These increase the flexibility, when they combine the harps and the dishes for lathe, without that it arrive to limit the performance and the hygiene of the solution of subjection. Besides, they could cause an increase in the rank of subjection or also in the depth of fixation.

Harps supletorias for the mechanised of bars, in dishes for lathe

The harps supletorias also increase the flexibility. They are combined with the dishes of lathe Broken NCD of Schunk. They use when sections or bars are mechanised in the same machine. In place to exchange constantly the dishes and the portapinzas, substitute the upper harps of the dish to mechanise bars, by these patented toothed harps. The toothed frontal in the harp combined with the own basic harp, warns that the harp of subjection go out during the mechanised. Even the small diameters of bars can be mechanised with precision. Therefore, the harps supletorias save a valuable time and high investments in dishes for special lathe.

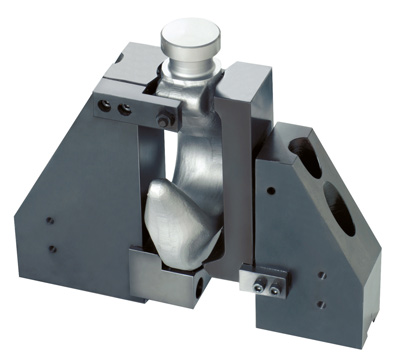

Special harps attach even the most demanding pieces

Although the harps standardised cover already a wide range of pieces, always will exist applications where do not arrive the ‘products of catalogue'. Especially in the mechanised of carcasas of hydraulics pumps, valves, pieces of smelting, in griferías, as well as in pieces in the rough, the special harps have showed his validity in several designs. Already they are harps pendulares of 12 or 24 points of contact, or with insertos of plastic, combinations of oscillating or fixed harps, manufactured of form totally individual, the possibilities of the special harps are almost infinite. They help to minimise deformations, compensate errors of geometry and even fix of safe form pieces geometrically very complex. Schunk, specialist in technicians of subjection and systems of hold know very well these possibilities. Around 50.000 special projects of special harps and a complete competition in the sector of virtual simulations serve to the innovative familiar company Schunk like base for his new special solutions. Only less than 2% of the applications are refused by reasons of technical difficulties. The time of realisation for the special harps is impressesive: the time average from the application until the delivery of the request of the special harps is roughly of 20 business days. Likewise the range of standard harps of Schunk is pioneering in the international field. Including more than 1.200 distinct types of harps, also the special.

The first app world-wide of harps

Five clicks in the Quickfinder of harps Schunk are sufficient to choose the ideal harp of the widest program to world-wide level. This tool includes like reference the dishes for lathe of Schunk and other a lot of manufacturers. The users can access to more than 1.200 types of harps and his useful accessorios. The customer can receive an offer in less than an hour. Besides the app of the harps includes a configuration to request standard harps modified and special solutions. This quickfinder is available to download in iTunes or in the different app-shops of Android under the words ‘Harps' or ‘Schunk'.