Which is your competitive difference like moldista / matricero?

Thus, the answer to the question proposed in the headline of the article would have to be any of the following:

- Optimise my productive resources to adjust me to the price that the customer expects

- My capacity of answer in front of repairs is sufficiently fast

- My fulfillment of the terms of delivery is consequence of the organisation of my workshop and of an acceptable internal communication

- The quality of finishing of my moulds is sufficiently good

- The learning of my personnel…etc.

Conscious of the previous,

It squeeze the resources

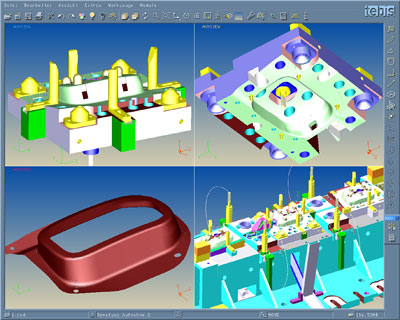

Mechanises several pieces at the same time?

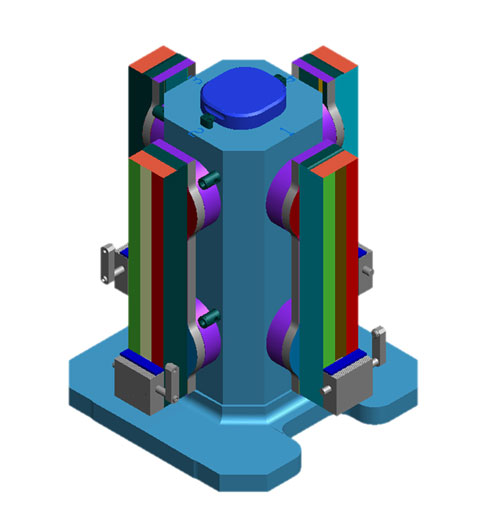

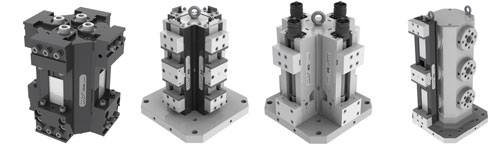

With the module for mechanised in die of tie up the programmer can order the sequence of mechanised of the different pieces tieed up by type of tool, by side or by piece, and with the system of mordazas double DSG of subjection of WNT mounted on dice of 4 sides can tie up of easy and safe form 8 pieces. These mordazas can go tieed up directly on the cube of subjection or, as it appears in the model 3D, on device of point zero type MNG of mechanical subjection, so that it can exchange the mordazas (p.And. To realise a different piece) of fast form and without need to go back to take ‘the zero'. In this type of subjection also facilitates a lot the work the use of the mordazas with systems of ‘third arm' as the DSG, when we put the piece of the inferior part this remains subject by the mouths and allows us use the two hands to put the piece of the top, without risk to that move or fall the first subject piece.

Optimises his time in workshop?

In the mould manufacturing and matrices, the costs in tools do not are used to repercutir strongly in the final prices of the pieces, because of the big value added of these, but the use of milling cutters of plaquitas himself that will suppose an extra saving, especially thinking in the big diameters; 16, 20, 25, 32 mm . The use of milling cutters with interchangeable plate also will save us time died of pre-reglaje to the hour to change a tool broken or worn, since the plates change without need to extract the mango of the strawberry of the cone tool holders.

It improve the capacity of answer

Loses time of production expecting receive a request of tools?

WNT Distinguishes by his service exprés of delivery of tools in 24h: the requests realised before the 19 hours deliver along the following day, avoiding long time of wait and helping to save in unnecessary stocks.

His machines work disregarded?

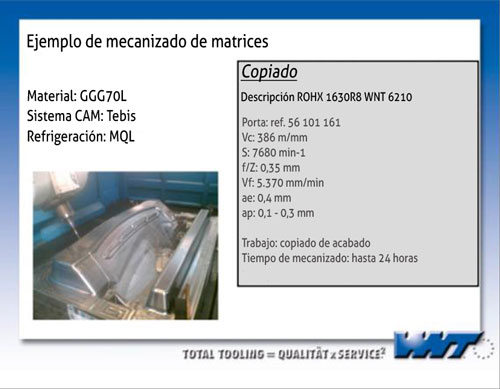

Surprises us find us with a lot of industries that have of a system CAM but do not trust fully in him. Proof of this is that they require that a person control the mechanised remaining of foot in front of a machine by fear to have a collision. This does not occur with processes programmed with Tebis thanks to the effective integrated cheese cheese simulation in the system. The simulator of Tebis bases in, by a part, that is a system to schedule the mechanised, that is to say, before beginning to program the user can know with which collisions can find , and, on the other hand, the once calculated programs can be verified with a hygiene of 100%. This translates in that any change is immediate since the simulator is a development typical of Tebis and no an application purchased to third as it is used to to be comun in systems CAM. Said in other words the simulators of conventional systems work with the file of exit CLDATA and Tebis realises the calculos internally, which gives him a lot of more flexibility and hygiene.

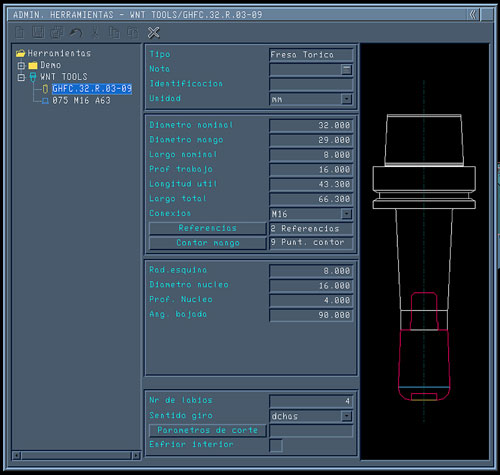

His technical office is agile modelizando and including parameters of tools of cutting?

WNT Has created a database with all his tools, included the most used for moulds and matrices, in files 3D, that can request through the commercial technician of zone or directly to the office, and that soon will be available to download directly with the keys of the customer of the web, to save time of measurement.

On the other hand the assistant for creation of tools of Tebis characterises by his simplicity in the design of tools, prolongadores and carry, as well as by the agile inclusion of the parameters of cut that his commercial of WNT will facilitate him.

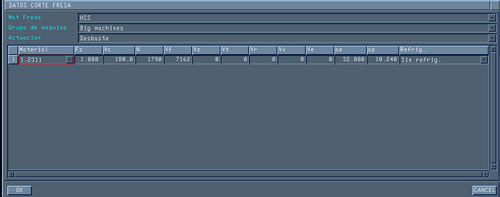

To way of example are the parameters of cut supplied by WNT and modelizados in Tebis for a tool tórica of diameter 32, designated GHFC.32.R.03-09, for the steel 1.2311 with hardness 52 Rockwell C:

- Mills of high advance, threaded extreme 32 mm of diameter

- Number of plates (lips) 4

- Size of plate of 9 mm

- Quality of plaquita CWX 26

- Radius to program 2 mm

- Vc = 180 m/min. => 1791 rpm

- Fz = 1 mm => Vf = 7164 mm/min (total advance)

- Ap = 0,5 mm (axial depth)

- Ae = until 32 mm

- Work in dry, with air

In our system CAM organise the parameters of cut according to the type of mechanised to realise, the group of machines, the material of the tool and the material to treat.

It improve his internal communication

Still consults heights in a flat form?

Each fresador, even with minimum notions of it, can have of a visualizador in his place of work, which avoids these unnecessary and repetitive queries between production and technical office.

Tebis Has of several levels according to the available functions

- Viewer: Allows to know in few second the evolution in the design of a piece.

- Organizer: This visualizador includes the functions of the previous and allows besides access to the databases and work with the both of mechanised. The organizer allows posprocesar any senda to another control directly on foot of machine.

Tired to create and print a list with the settings of tools for workshop?

Once defined the processes of mechanised, and mattered the geometry and parameters of the tools in digital format, Tebis generates automatically a pdf with the sequence of necessary tools in each process of mechanised, obviously if they modify the tools used a process, said listing updates automatically. The fields of this listing can be edited to taste of the user, which facilitates his inclusion in the norm ISO 9001.

In said document specifies the total length of the tool, as well as the length of work, of such form achieves that in workshop realise the correct setting of the tool.