Flying high with wings manufactured in Palencia

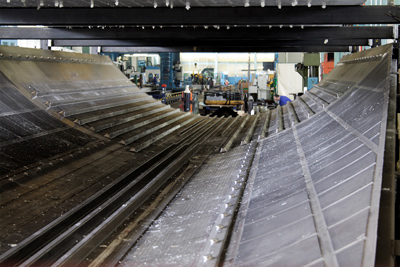

If they fly the next time by holidays or businesses with an Airbus, can remain calm as it is very likely that are surrounded by the product of the work of engineering of excellence realised in Palencia. Here, in this province of the Community of Castile and Leon, Inmapa manufactures complex parts and components of the Airbus To380 and To350, for the wings and the stabilizer, as well as diverse others for the external structure and interior of the aeroplane. The team of the magazine ‘Klartext' visited the plants of manufacture and interviewed to the managers of production and control of quality.

Development imparable

Vast experience with the TNC

“The numerical controls Heidenhain characterise for being very reliable. It is more, we have not spoilt never an alone piece by fault of a control”, relates Gregorio Vián, manager of the department of Control of Quality of Inmapa. This is not lower thing, considering that the company works from does more than 30 years with diverse TNC.

Vián Is in the company almost from his starts and account that in more than three decades has put to proof the distinct models, beginning by the compact TNC 135, following with the TNC 155, afterwards the TNC 426 (in his original version and more advanced), for more advance to employ the iTNC 530.

The big compatibility between the different numerical controls has been always a big advantage along the time: “Nowadays still it is possible to use programs of mechanised of does some years backwards. To realise new mechanised of similar characteristics require only few adjust in the program”, recalca Vián.

Even the smallest ‘controls' understand the programs elaborated in the biggest ‘', with the alone exception of some specific functions. The good compatibility of the controls Heidenhain has been a contribution for the efficiency of the processes of manufacture.

I handle very confortable and profitable

Consulted with regard to the concept of conversational programming of Heidenhain, Roberto Gil, responsible of manufacture of Inmapa aeronautical sector component manufacturing sector component manufacturing sector component manufacturing, shows more than satisfied: “it Is simply fantastic and relieves us the life enormously”. It explains besides that, thanks to his simple handle, does not require long to learn to operate a control. “To the 3 days any person with technical knowledges is able to work with the numerical controls Heidenhain. This is due to that the control goes guiding and aleatherg enter the basic data or the necessary coordinates for the mechanised”, explains Gil. That is another big advantage for the company to the hour to incorporate new operarios, when the volume of work increases a lot, for example by some project especially. Besides, in the case to change to a TNC more modern, the operario does not have to learn again, but simply familiarise with the additional functions.

Another appearance of the confortable handle of the controls is the simple selection of cycles: “they Are very easy to select and use, since the control goes guiding to the operario step by step”, stands out Gil.

aeronautical sector component manufacturing sector component manufacturing sector component manufacturing: fulfilling maximum exigencias

Inmapa Devotes to the manufacture of parts for this aeronautical sector component manufacturing sector component manufacturing sector from the year 2002. The size of the pieces to mechanise goes from the few centimetres until several metres, if we consider the components of the wings of an aeroplane. The challenge here is to offer a quality of the highest level in the final product. Customers so important like Alestis, Embraer, EADS or Airbus expect only the best of the best. To have an idea, the tolerances regarding precision are in the order of a maximum of 15 micras, being even more strict for some components.

With the help of the numerical control iTNC 530 of Heidenhain (incorporated to all the machines and machining centres of the plant of aeronautical sector component manufacturing sector component manufacturing), Inmapa realises works of mechanised very precise and of five simultaneous axles. “The iTNC 530 has allowed us arrive to the current level of precision and fulfil with very high exigencias of quality”, recalca the boss of Production, Roberto Gil.

Inmapa aeronautical sector component manufacturing sector component manufacturing sector component manufacturing uses this type of numerical control for mechanised of high speed, with a control of path especially free of shakes, important appearance to the hour to work pieces of big dimensions. The mechanised in 5 axles —with cabezal basculante and rotary presses table — “are easily programmable, thanks to the concept of conversational programming and to the confortable operabilidad of the control”, stands out Gil. And all this taking into account that the diverse parts to produce are of high complexity, so much for the carcasa as for the interior of the aircraft, and thus they require of a very precise programming of the curves.

Another challenge for the technicians and engineers of Inmapa is to keep the quality of the pieces, without mattering if these are of aluminium, titanium or invar. Like this it is like the company manufactures, for example, the moulds of aluminium to give form to the rear part of the aeroplanes or the wings. These moulds do the function of a species of container for the fibre of carbon to be compacted by Airbus in a back step. The moulds and the slots of the wings are manufactured with maximum precision thanks to the iTNC 530.

Among others metals, Inmapa also works the invar. It treats of an alloy of nickel-ironinging that has the peculiarity of practically conserve his original form, independently of the eventual fluctuations of temperature that can present. When beginning to work this new metal, the iTNC 530 was used like help to measure, program the curves and realise the simulations of mechanised necessary, until obtaining the current optimum results.

Flexibility and precision

One of the characteristics of the group Inmapa is the diversity of his lines of business and of the products delivered to his customers. “The versatilidad of the controls Heidenhain allows us tackle a wide range of works of mechanised”, recalca the manager of the department of quality, Gregorio Vián. Like this it is like the company is able to manufacture products and components for diverse sectors of the industry mechanical metal and for technological multinationals.

In the case of Renault, for example, the controls Heidenhain have contributed to the automation of processes in the manufacture of matrices and also of the doors of the trucks via patterned. With the TNC 426, and now with the iTNC 530, is possible to realise the exact programming of the curves of an ironinging of metal and of his corresponding orifices for the exact position of the doors. The high precision of the mechanised allows an optimum assembling and replaces the manual process and the back welding.

The best proof of the wide possibilities of mechanised that offer the TNC, is the diversity of projects in that it participates today Inmapa. The company realises from does almost a diverse decade components (wheels, axles, freamers) for the rail industry. The common denominator in all these works is always the same: his excellent quality and the numerical controls Heidenhain.