Topics for the future in the construction of machine tools

on June 14, 2011

It is precisely in the tense area between the demands of the clients and the work of development where the advantages linked to the strategic location, as a high level of qualification and motivation as well as an excellent industrial infrastructure, can help create these innovative solutions through knowledge integrators.

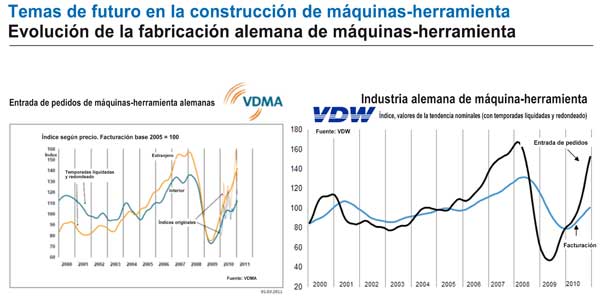

1. Current economic situation

Order intake in the German sector of the construction of machines is a recovery of the market in early 2011 after a clear depression during the economic crisis of 2008 and 2009. Figure 1 (left) shows that, according to the indications of the VDMA, the orders from abroad have almost returned to the level of the years 2006 and 2007, while the inner orders still not have been able to match. However, the trend is rising, so the German sector of the construction of machines can look confident in the future.

Picture 1 (right) shows the order intake and revenues of the German machine tool industry. In view of both data on construction of machines and construction of machine tool orders clear analogies can be detected. In this case, the trend from 2008 and 2009 is also clearly upward. In addition, should recognize that, thanks to the complete portfolio of orders before the crisis and the relatively long periods of development and manufacturing products, during the crisis failed to completely falling revenues in the sector of the construction of machine tools and also reacted quite late to order intake (about 1 year). Therefore, you can predict that the large increase in order intake which is recorded from 2010 onwards may rise again this year the turnover of the German machine tool industry.

It is precisely in a phase of growth in the market like this when it is important that companies stand out against its competition. Whereas the share of exports of German industry of machine tools (64.3% in 2009 according to VDMA and VDW), of which especially is imposed on international competition. Unlike the competition from other countries (especially in the far East), German companies have chosen so far to continue taking advantage of the technological edge that gives them their location in countries with high salaries. However, in the segment for machine tools of price means it is clear that manufacturers in the far East also compete in this demanding market segment technologically.

In the next few years should keep the existing differential advantages and develop new ones. In addition, the construction of machine tools involve changing conditions. For example, in recent years also has gained influence in this sector the subject of energy efficiency and has to take into account throughout the life cycle of the machine - but a sharper way in the phase of development - and also clearly indicates the campaign Blue Competence of the VDW.

2 Field of tension between the demands of customers and development work

While the requirements for products are independent of the location, the optimal organization of the development and manufacture of the product and, therefore, the conditions part of manufacture of the product depend on the location of the company and the corresponding commercial environment. Each company has its own point of operation that works optimally. For countries with high wages, for example, high wage costs and the lack of technicians they counteract with the high level of qualification and motivation and excellent industrial infrastructure as distinctive signs relating to the site. Therefore, the potential of high-wage countries lies in the promotion of knowledge integrators taking advantage of the broad level of qualification of workers as a key actor in the success to take advantage of global opportunities.

In what refers to the process of development of a machine tool, face the requirements of the customer profile and the development of the manufacturer of the machines work. When customer is directed to the manufacturer of machinery with technical and economic requirements, this needs to be adapted to them in the development with the greatest possible efficiency (illustration 2). A company in a country with high wages can benefit in this area by integrating knowledge and the high level of qualification. It is precisely at the current stage of growth when it comes to meet the demand of customers on maximum productivity combined with a high return. However, the conditions external, as for example the demand political and economic to consider and to optimize the energy efficiency of protection facilities, have been also vector new demands in the methodology of development of the manufacturer.

3. Potential differential advantages in international competition

The developments in the sector of the construction of machine tools are characterised by new high-tech solutions and maximum satisfaction of needs. Thus, the German sector of machine tools is still currently in a prominent position on the international arena. To protect the advantage in international competition can be considered innovative developments especially in the areas of virtualization of the creation of products, mechanical concepts adapted to the demands, automation, high-performance and Condition Monitoring components. All optimization measures tend to a minimization of the costs of investment or the minimization of the different portions of times of manufacturing of the components. In addition, adjustments occur in the new status as a framework for energy efficiency, at present, also influencing the creation of the product.

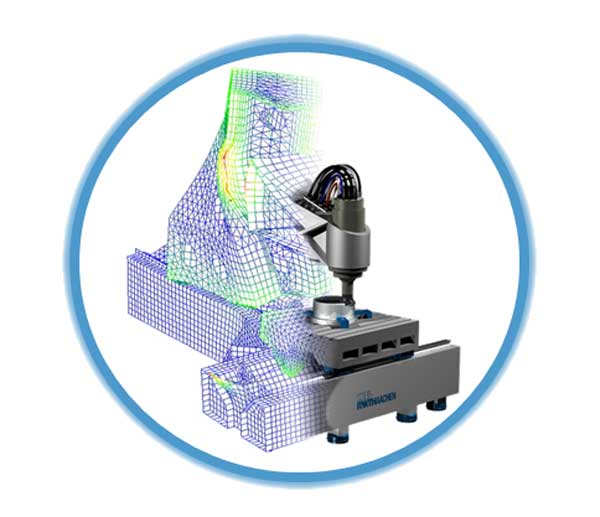

Currently, in the construction of machine tools increasingly are used more simulation tools at all stages of development to be able to optimize the performance of the facilities even with future shorter product life cycles. The simulation techniques which are available already now allow the reproduction of different aspects with a variable precision. Simulation models should be adapted to the objectives of the manufacturers and users of machines, both for production by boot of shavings as for forming.

To minimize the costs of development of a wide range of products adapted to the needs, today is ever more frequently Modularization also used in the average price of the machine tool segment. The basic idea here consists of dividing a system into interdisciplinary components that can be returned to use in different facilities and machines. The automation of work pieces as a measure of productivity is now more and more in the scope of functions of the machine tool manufacturer.

Following the example of the integration of several processes of production in a structure mechanical hybrid, these additional tasks leads to increased mechanical complexity, control and security that should answer the manufacturer of machines with methods integrators in the development of products. The mechanical components must also raise at best levels of performance through the continuous increase in the productivity of production processes and with efficient tools. While in the area of the linear axes are always demand higher accelerations, in the main spindles are increased continuously moments of rotation (HPC) or the necessary number of revolutions (HSC).

These new demands can negatively affect the conduct of precision and the duration of the components. It is precisely in the area of life where they must develop and verify robust models that include the new framework conditions. From now on will have to consider approaches to the inspection of the State of the components during operation and integrate them into the machine.