Harnessing the potential of the machines to improve energy efficiency

on June 6, 2011

For operators of machines, the energy costs of production machines are currently a large block of costs. An increase in energy efficiency with the same or even greater productivity, is one of the starting points most important to reduce the costs per piece in a sustainable manner. For Bosch Rexroth in his capacity as automation and supplier of all the core components of a machine tool company, energy-efficient components and system solutions are a feature of very important differentiation. The manufacturer has very soon faced the challenge of energy efficiency and is now in a position to demonstrate the first concrete successes.

The overall strategic basis is the strategy of energy efficiency 4EE-Rexroth (Rexroth for Energy Efficiency). This grouping, structure, compares, and focuses on a number of technologies and solutions that help all use energy wisely. In this sense there are four starting points that turn out to be determinants: energy-efficient components, energy recovery, made available to the energy consumption and an optimal configuration of the system. The basis for the reduction of the consumption of energy in the production area are some energy-efficient components with high yields for pneumatic, and hydraulic actuation technologies as well as the linear technique. In this sense, the freedom of choice and the possibilities of compensation between these technologies represent the basis for energy-efficient solutions.

The second point is the energy recovery: recover the excess energy, store it and use it in accordance with consumption within and between different drive technologies, is the key to the new and innovative energy-efficient solutions.

All addition implementation available to energy according to consumption which means that at any given moment only supplied to a system, the volume of energy needed by the relevant service in order to minimize the total losses and thus optimize.

Finally the system configuration is also crucial. This can be optimized through the use of software tools that are available for the configuration and definition of systems to complex simulation and that enable a sizing in accordance with the work of the functional modules required in each moment. You can be a significant energy savings especially when looking at the system as a whole, throughout the life cycle, from design, passing through the service and to the modernization.

Over the past years, Bosch Rexroth has accumulated extensive experience with potential energy efficiency measures, both from the point of view of an operator of machines of a manufacturer of drives and controls. Below are for example some of these measures.

Consistent disconnection

In the case of a typical machine of production, only the provision of service for the production consumes 55% of the energy. If there is a sleep mode that allows to disconnect all users with the exception of the control, the machine remains in provision of service for the production for all stops caused e.g. by a lack of parts. The possibilities of energy saving are not used.

Bosch internal analyses have shown that a consistent manual disconnection during planned and unplanned breaks saves around 12% and the automatic disconnection some 25% of the energy. In this sense it is important that not only turn off the machine as a whole but also the different functional modules if they are not needed during a certain period of time, even with production underway.

A manual disconnection can be done in some cases virtually without making any investment. It is only necessary to sensitize employees in regards the energy costs. In return, an automatic disconnection of the machine, as well as some specific functional modules requires an adaptation from the software which is usually scheduled within the framework of a retrofit measure and which should be mandatory in the case of new machines.

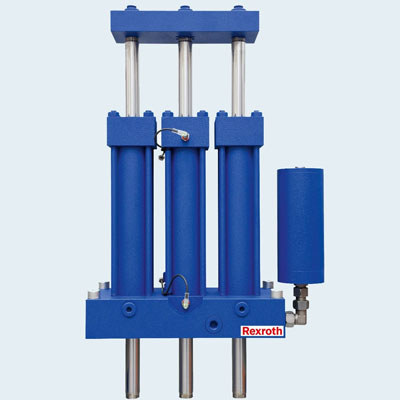

Hydraulic cooling lubricant KST-Booster

Depending on the machine and the task of machining, up to 60% of the energy needs of a production machine is required for making available and the preparation of the cooling lubricant. In the case of the observed machining center, the percentage of the coolant has been almost 30%. The preparation of the lubricant is outside the machine at a central facility.

The coolant lubricant Rexroth KST-Booster allows you to use a generation of high-pressure coolant lubricant and hydraulic energy-efficient and forward-looking process with adaptation of the flow and pressure, completely without losses caused by derivation, even with the smallest tool diameters. In this sense, hydraulics attaches directly to coolant lubrication technique which involves the removal of a complete line of electric drive and that you can perform optimally in a machine of machining by changing between the need for hydraulic lubricant and coolant lubricant. In the event of a low coolant oil consumption, energy saving over 50%.

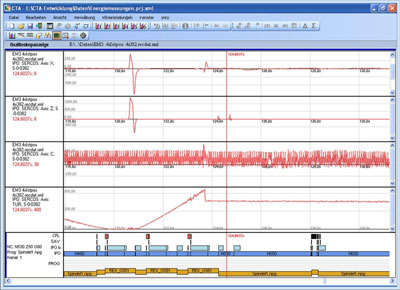

Power and energy consumption monitoring

Thanks to the greater transparency that contribute, indications of energy consumption also help in case of production machines to a more ecological behaviour by users. A display of power allows the user observe and monitor the power consumption of a machine, as well as the different functional modules (which are electric drives and secondary groups as, e.g. hydraulic pump, coolant lubricant pump).

Using a screen of energy you can join and monitor energy consumption of a machine, as well as the different modules functional over defined periods of time. The solution of the system Indramotion MTX includes both the tools for the monitoring of energy (a display of power and a display of energy) to the end user as also the tools of analysis (analysis of the time of cycle MTX cta and the analysis of MTX energy ega) for production technician or specialist in energy that are striving to achieve a reduction in energy consumption.

Offer of services

Over the past years, Rexroth has introduced several new services in relation to the issue of energy efficiency. Energy check includes verification of the machine in situ and the creation of an energy report is divided into electrical, hydraulic, pneumatic energy consumers and other.

On the basis of this energy Checkup, Rexroth elaborates a concept of energy optimization for the machine which also includes the same process. As classic service, Rexroth offers the modernization of the machine by using a preconfeccionados modules.

From approximately a year ago, Bosch Rexroth uses energy advisors who advise clients in a direct way on the subject of energy efficiency. Its main task is to show the weaknesses in the existing machines and propose improvement measures. In the case of new machines which are still in the development phase, put at the disposal of the client all their intratecnológicos knowledge and are the link between the client and the Mechatronics support specialists.

Perspective

The above examples demonstrate the following: in the area of production there is a technology which alone objects of efficiency to reach those who are aspiring but is rather the sum of the different measures that counts. Thanks to the intelligent linking of the different measures can be obtained very considerable savings. Bosch Rexroth offers products and solutions at the moment to give a response to the demands of customers who demand the highest energy efficiency.