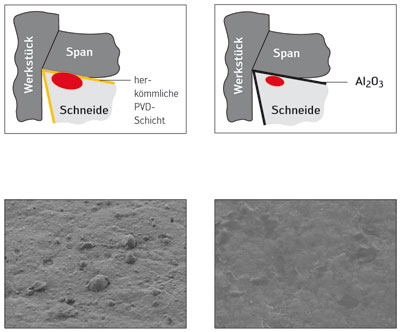

Materials of cut of high performance thanks to the coating PVD with oxide of aluminium

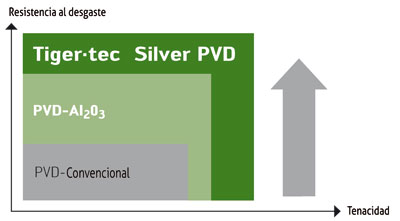

This supposes an extraordinary resistance to the desbaste thanks to the To the2Or3 and, at the same time provide some good properties in tenacity. This is because of the fact that the process PVD requires a significant lower temperature, around 500 °C. Besides, the coatings PVD are subject to tensions of residual compressesion, by what there is a significant lower influence on the properties of the sustrato. The coating PVD-To the2Or3 creates therefore a material of cutting that is the one who more approaches to the material of ideal cutting ‘rubber of Diamante' (that obviously only exists in the theory) of the known to date.

The aims of the experts in materials of cutting can see in the two lines of development of Walter Tools. The aims here are the optimisation of the coatings PVD to reach a greater resistance to the temperature and optimise the coatings CVD to improve his tenacity. The distance between the coatings CVD and the PVD therefore, does smaller. In other words an approximation to the material of ideal cutting comes from by both steerings. As such, the crossing of the coating PVD with oxide of aluminium with the technology Tiger•tec Silver represents a logical step for Walter. PVD Tiger•tec And Tiger•tec Silver then join to create the Tiger•tec Silver PVD.

Everything begins with the ranurado

The company is launching this material of cut for all the applications of mechanised with a method step by step. This begins with the ranurado with the quartet formed by WSM13S, WSM23S, WSM33S and WSM43S. The two intermediate degrees in reality already cover the majority of the applications of ranurado. This is particularly true with the degree WSM33S, that Walter recommends for the majority of the ‘standard conditions'. This degree offers us an ideal relation hardness-tenacity for the majority of the applications. The hardest degree WSM13S, on the other hand, offers the maximum performance for applications with conditions of mechanised stable, for example, in applications of finishings in disks and carcasas of Inconel. The degree more tenaz, the WSM43S, has been designed for conditions of unstable work and with cut interrupted. The four degrees of material of cut are adapted for all the groups of materials to mechanise. During the ranurado, the conditions of mechanised are always specific, by what the group of material ISO has less influence in them. The operations of ranurado usually need a material of cut with a high tenacity, what means that material of high performance of cut like the Tiger•tec Silver PVD also can play with his fortresses in the mechanised of steels. Those that use these degrees, to do the necessary adjust fine only need to select the rompevirutas suitable. With the four materials of cut of high performance already mentioned, the manufacturer with base in Tübingen offers us a wide range of geometries for the tronzado and the ranurado.

In a comparative proof, the new degree WSM33S competed with his predecessor, the WSM33, and against other products. The task was ranurar and cut in the tracks of the threads of balls in material 100Cr6 (1.3505). The PVD Silver Tiger clearly took them out a head in terms of life of tool and produced 950 pieces, 150 pieces more than his predecessor. Other coatings PVD conventional only reached at most the 450 pieces in life of tool. According to Jörg Drobniewski, “the proof shows that we have surpassed with the Tiger•tec Silver PVD to our own performance. As such, are expanding our position in the market of coatings PVD that already was occupied by the PVD Tiger. The coating PVD with oxide of aluminium situates to Walter in another stair inside the international market of tools”. En el futuro, the signature prepares to launch the corresponding degrees to milling and to turning ISO during the next two or three years, changing the previous degrees Tiger•tec PVD to degrees Tiger•tec Silver PVD.

The optimisation of the adaptation of the size of the plate to the piece and to the past gives like result a saving of costs and also a reduction of the resources of dust of hard metal. Walter has taken this in account when expanding his rank of interchangeable plates of the family Tiger•tec Silver ISO P. In some cases where the plate used is the CNMG1204, the plate of inferior size CNMG0903 can be sufficient.

The fact that the ‘small ‘' in a lot of cases result to be the true ahorradores of costs since when having a lower cost overlooks . Walter therefore it has incorporated the size of plate 09 inside his family Tiger•tec Silver for the turning of material ISO-P. With the intention to cover all the typical applications of these sizes, the users can choose between the following basic forms CNMG0903, SNMG0903 and TNMG1103 in two rompevirutas FP5 and Mp3 for the works of fine-tune and mechanised half. All the geometries are in negative plates, what allows us have the maximum number of edges of cutting. The forms ‘C' and ‘S' have eight edges of cut, whereas the form ‘T' has six. The operations that like rule, before did with small positive plates, now also can be done with negative plates much more efficient in costs (examples can be mandrinados interns of small diameters, mechanised in machines multihusillos with loaders of bar, etc.) with the advantage added of the savings obtained by the utilisation of the new family of materials of cut Tiger•tec Silver. His excellent productivity (+75%) has been already showed in a lot of occasions, and of course, the profit of the production where small past are required.

Walter supplies system of tool holders for the mechanised internal and external and these same systems of tie up are standard for these small plates, including bars of mandrinar with internal refrigeration beginning in diameter of 16 millimetres. For mechanised external, the user can choose between fixation by brida or by crowbar, beginning in cuadradillo of 12 millimetres. The rank of tool holders takes into account all the types of turning that find usually.

Beside the extension of the small plates, the rank of Walter is also growing. For example, the two rompevirutas of negative plates of an alone expensive NRF and NRR for the mechanised universal and big desbaste, already have them in the family Tiger•tec Silver. For example for the mechanised of pieces forged until 18 millimetres of past.

An innovative concept in the milling

The generation of milling cutters Blaxx, very hard thanks to his powerful ‘properties, precise and reliable' that, deserve the attribute of ‘noble', for which has created an innovative concept of tool with the highest possible technical level and with an entirely new finishing in brilliant black. However, this finishing is not simply appeal visualmente since it also has the function to be extremely resistant. It reduces substantially the effects of the desgate and the corrosion. The high precision of the seats of the interchangeable plates hold the edges of cut like the knights hold with his gloves forged his brilliant swords. Instrumented with these characteristics, the first tools, two milling cutters of escuadrar F5041 and F5141, explain in addition to tangential plates like an extra characteristic. On the one hand, this allows us an extremely stable design and, on the other hand, provides us a big volume of hard metal in term of strengths of cut, for example, an upper level to the average in reliability of process. The result is a robust design, that guarantees us a mechanised silent without vibrations.

The plates of precision produced in sizes LNHU0904 and LNHU1306 have four edges of cut positivizados. The high level of concentricidad of the body, the scarce jump between plate and plate and the 90º just in the piece mechanised, ensure us exact results. With this plate, can obtain depths of past until 12 millimetres. Since the accommodations of the plates and the zone of evacuation of shaving demand less material of the body of the tool, can achieve diameters smaller, whereas it can place an upper number of teeth (plates) in the same diameter. The tools of escuadrado Blaxx are available from a diameter of 25 millimetres. Instrumented with more edges of cut, also allows us until 30% more than linear advance.