The male multiaplicación

In comparison with other modalities of mechanised with rotary presses tool like taladrado, milling, escariado, the thematic associated to the threaded with male presents some levels of complexity notably upper owing to the variety, volume and economic technical/scope of the group of the variables involved.

Occupies preferential positions in the ranking so much by volumes of operation (the third place after taladrado and milling) as by economic responsibility —the first position—for treating with frequency of a final operation that culminates a process of mechanised multiple.

From a conceptual punto could define a thread like an arrollamiento espiral of a thread with a clear-cut geometrical profile, being the most usual triangular 60 º for being the corresponding to threads Metric System DIN-ISO and threads of the system ANSI (USE).

From the functional punto the committed more important of the threads can englobar in 2 big areas:

- Like elements of union /fixation mainly.

- Like elements of accionamiento in lower proportion.

The binomial male – thread of roscar

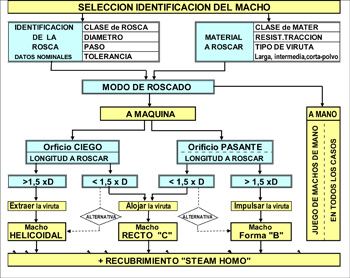

To title of orientative reference the diagram that appears to continuation ‘selection/identification of the male of roscar' collects a panoramic general of threaded with male. In accordance with the same go to realise a review abbreviated of the main factors involved.

Foundations of the thread to mechanise

This chapter composes of 3 areas or fundamental sections:

- Characteristic of the thread

- Characteristic of the orifice

- Characteristic of the material to work

1) Characteristic of the thread

Like initial premise, results imperative to identify with clarity the basic characteristics of the thread to mechanise: class of thread, measure, step and tolerance.

To explanatory effects go to take like referential example a thread M 10 x 1,50 6H.

M: the data does reference to the class of thread. In this case Metric thread, regulated by the Rule DIN–ISO. To this respecto indicate that to world-wide level exist 4 big normative:

- DIN-ISO: predominant European System in Europe and in constant growth in the rest of the world.

- ANSI: System USES predominant in North America, Centre and South

- JIS: Japanese System, predominant in Asia)

- BSI: British System limited to the area of Anglo-Saxon influence

All this configures a big number of types of thread whose relation can consult in the norm DIN 202.

10: this data does reference to the nominal measure of the thread in mm. To this respecto indicate that the threads of the system ANSI (USE) and BSI (British) the data expresseses in fractions or decimals of inch (example: 3 / 8” equivalent to 9,525 mm).

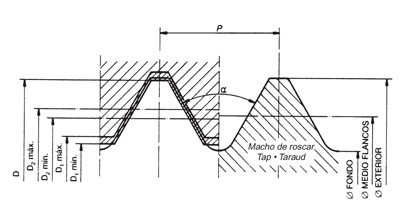

- external Diameter (or nominal diameter): it measures on the crests of the threads and his levels of criticidad /exigencia with regard to the precision are inferior to the diameter of flanks.

- Diameter of flanks or half diameter: it measures on the virtual line that discurre longitudinalmente by the half point of the profile of the thread, dividing exactly between 2 the step, generating therefore, identical magnitudes between the portion maciza and the portion vaciada of the profile of rosca.es the parameter determinante in the tolerance of the thread and therefore his level of exigencia is the most elevated of the 3.

- Diameter of the core or bottom: it measures on the bottoms of thread and his levels of criticidad/exigencia are notably inferior to the others two parameters.

1,50: is the step of thread or distance between two contiguous profiles, expressesed in mm. In the threads of the systems ANSI (USE) and Anglo-Saxon BS, the data expresseses in Number of threads or profiles in 1 inch (example: 16 threads, 25,40/16 =1.5875 mm). It is a parameter highly critic for the precision of the threads and in consequence is subjected to severe exigencias of Tolerance to level of unitary height comma acumulativa in the successive steps along the threaded length. Said tolerances are fixed by each one of the Rules and with general character the maximum error admitted is 0,10% roughly.

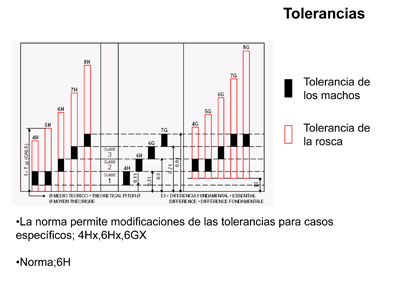

6H: does reference to the diametral tolerance of the inner thread in the system DIN-ISO. In combination with the tolerance of the external thread determines the level of adjust between both.

Corresponds to the Half class (6H nut - 6g screw) of the 3 typical qualities Fina, Average, Thick and sobreentiende like the typical normal tolerance whenever of way expresseses do not indicate another quality. The structuring of the tolerances in 3 categories, Fina, Average and Thick is a common criterion in all the rules.

Felt of the thread (to right / to left): Like criterion estandar sobreentiende that the thread is to right: twist of atornillado in time sense, seen from the head of the screw. The option to left (opposite to right) is of utilisation marginal and will be object of indication expresseses and specific treatment.

2) Characteristics of the orifice

By causes that explain in the description of the male, the typology of the orifice to roscar constitutes a factor determinante for the threaded with male. Therefore the suitable identification of his characteristics: form or type and depth or threaded length constitutes the 2ª fundamental premise.

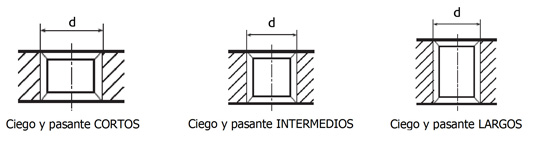

Although the casuística is very wide, to practical effects can group in 6 main variants (2 types x 3 threaded lengths in each one of them):

blind Orifice (without exit): with Short threaded length (≤ 1xD), Average (1,5 xD), Long (2,5xD);

Orifice pasante (with exit): with Short threaded length (≤ 1xD), Average (1,5 xD), Long (2,5xD), (D=nominal diameter of the thread).

3) Material of the substrate

As in all operation of mechanised, the importance of the material worked results totally obvious in the threaded with male.

Given the wide spectrum of factors and conditions that take part in the characterisation of the material, from the practical punto interests his simplification to the possible maximum, always inside rational limits that guarantee the levels of efficiency required.

In accordance with the quoted resumimos the thematic in 3 conditions genuinamente representative: Class/ nature, mechanical Characteristics and Typology of shaving.

• Class / nature

In the context that occupies us centre the subject in metallic materials of use more common in the industry of Mechanical Manufacture and areas aledañas:

- Steels of mechanical construction (drop and half alloy)

- Steels aleados for thermal sensors treatment

- refractory stainless / Steels preferably austeníticos (AISI 304, 316 and similar)

- Foundries, preferably Nodulares (GGG).

- Aluminium and alloys with contents of Silicon ≤ 8%

• Characteristic mechanical

centre Them in resistance to traction and/or hardness, with preferential limitation to a maximum of 1000 Mpa (350 HB). In the specific section of threaded by laminación or conformed plastic —roll forming— without desprendimiento of shaving, is necessary to take into account, besides, the plasticidad or coefficient of plastic deformation (no inferior to 10%).

• Type of shaving

Is a directly associated factor to the two previous and to effects of practical simplification resumimos 3 referential types: long, typical of materials of reduced hardness and/or high plasticidad in general, like steels of low alloy, stainless and low aluminiums in If; intermediate, typical of materials of intermediate hardness and/or half content of Carbon >0,50% or steels of easy mechanisation, aleados with strategic addition of Pb (lead) or S(sulphur); and very short/dust, typical of foundries.

The male of roscar

Can define it like rotary presses tool of cut of precision specifically designed for the mechanised of inner threads. Therefore the tool by excellence for the object in question.

From the global technological punto can distinguish 2 main typologies:

- Male of laminación (rolling tap) that works by technology of conformed plastic without presence of shaving. His volumes of utilisation are very inferior to the male of cut in spite of his properties and potentialities and his treatment would occupy a wide chapter that in principle remains out of the present work.

- Male of cutting (cutting tap) that works by technology of cutting or desprendimiento of shaving. It is the predominant type to universal level and inside the same like exponent stood out the male multimetal that occupies us in the present work.

Speed of work in threaded with male

To title aclaratorio in front of possible errors of concept, consider necessary to do upsetting on this important subject. In the mechanised of orifices in general (taladrado, escariado, threaded with male) the effective speed comes determined by the rhythm of axial advance or speed of advance. The speed of twist or tangential is a complementary factor. Under this premise results evident that the male of roscar is, per know, a tool of high speed owing to the high speed of advance been due to his peculiar mechanism of work. In rare consequence time the threaded with male constitutes a neck of bottle from the perspective of time of cycle.

In comparison with the taladrado with broaches of hard metal —of high speed— the ratios of advance x 1 rpm of the male are until 10x upper, by what rare time the speed of axial advance of the broca reaches to 75% of the axial speed of the male in spite of the difference in tangential speed or of twist (rpm) favourable to the broca (proportions of 6 x.

Mechanisms of work of the male of roscar

The fundamental mechanism of performance of the male characterises by an exclusive condition and determinante as it is the supeditación of the twist, to an only value or ratio of advance, with what the value of the advance x 1 rpm has to be exactly the same to the value of the Step of thread. It is what knows like synchronisation.

Of the fact derive 2 main consequences:

- Any possible error, by excess or by defect, in the accuracy of said synchronisation comports unavoidable negative consequences, well in the quality of the thread ploughed (measure and finishing) and/or in the own life of the tool.

- All partial twist of the male, forces imperativamente to an axial trip of proportional magnitude to the value of the twist.

The final consequence is that the success in the threaded with male, is severely supeditado to the factors associated to the synchronism turn - advance.

important Notes

In the practice, the obtaining of a precise and permanent coordination between both synchronisms —the typical of the male and the typical of the system of advance— in all the phases of the threaded (advance, unemployed, investment, shrinking)— can result complicated in determinate situations and/or circumstances, even with systems CNC advanced. Only the known mechanical system by means of husillo pattern offers full guarantees and in fact is used with optimum results by several manufacturers of prestige, of skilled machines in threaded with male, without obstacles for his combination with systems CNC.

In the practice the problematic associated to possible errors of synchronisation, resolves with the utilisation of an element of fixation of the male or portamachos, endowed of axial flotation (retractable elastic trip to traction mainly (field 25% minimum of the length to roscar) and compressesion (field 20% roughly of traction). The axial flotation acts compensating permanently the possible errors of synchronisation. On the other hand, and without obstacle of possible divergent opinions, can ensure that this device does not comport risks of negative effects in no case.

In addition to the previous, the utilisation of gifted systems with limiters of pair or embragues, can result beneficial in theory but in the practice present complications of notable character that question his utility.

Characteristic fundamental of the tool

From the functional punto the global quality of the male of roscar is the result of the sum of 4 partial qualities interactive:

Quality of the material of the substrate and appropriate thermal sensors treatment + dimensional Geometrical –Quality + Quality of rectified+ Quality of finished/superficial treatment.

To referential title go to realise a brief recapitulativo.

• Material of the substrate

The fast steels or súper fast constitute the practically totalitarian option, with a participation marginal of the hard metal WC carbide of Tungsten. The reasons are of technical order and root especially in the indisputable upper tenacity (minimisation of risks of fragility) of the fast steels with regard to the carbides, in spite of the remarkable progresses experienced in the last.

Inside the fast steels stand out the 2 specific qualities: M2 (1.3343, S 6-5-2) that it is the fast steel by excellence until the point that his real capacities can result insufficiently appreciated in some cases and M35 (1.3243, S6-5-2-5) quality that on the base of the M2 incorporate Co (Cobalt) in his content of alloy, what contributes him an appreciable improvement in thermal sensors resistance (hardness in hot) to work to speeds of cutting very high. Like contrapartida increases moderately the fragility.

Both materials are the used in the males multimetal.

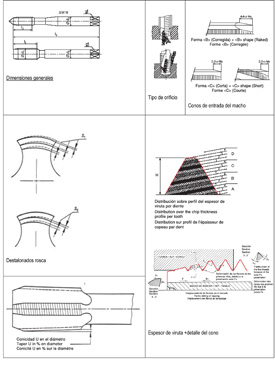

• General dimensions

understand like such the total length, length of head (orientative), diameter of the mango or topmast, measure and/faces of the square of drag. These parameters are defined by each one of the big normative to world-wide before quoted: DIN-ISO, ANSI, JIS, BSI and are different for each one of them. The males multimetal answer to the rule DIN –ISO.

• Measured diametral of the thread

The diametral measures of the thread of the male are strategically dimensionadas —by means of criteria collected in the corresponding rules— to obtain the tolerances demanded in the thread to mechanise.

To title of observation stand out that by technical reasons of some complexity (levels of effort and friction), the male does not realise the mechanised of the diameter of the core or bottom of thread by what this diametral measure is obtained in the previous phase of mechanised previous of the orifices.

active Geometry

Engloba the group of forms and geometrical elements directly involved in the mechanics of work of the male of roscar.

Slots or groove: In addition to configuring the face of desprendimiento or cutting and therefore the angle of cut, are the elements that commission of the accommodation and/or evacuation of the shaving cut and of the driving of the fluid of cutting or refrigerante.

Have a direct relation with the type of threaded to realise and from a global perspective identify 3 main typologies:

- Groove straight (straight flutes): typical in the male games of threaded manual. In work to machine apply for threaded of blind orifices or pasantes short, ≤ 1xD in general, as well as long ≤ 3xD in particular cases like foundries. They can not displace the shaving and therefore have to lodge it in his interior, by what the relation volume of shaving – capacity /space of accommodation results paramount.

- Groove helicoidal (spiral flutes) typical for extraction equipment equipment of the shaving in threaded of blind orifices with depth >1xD. In case of need this type can roscar any type of orifice although they reduce the levels.

- Straight slots with form espiral in a determinate zone of the tip or entrance of the male, also known like form B, Gun or Entrance corrected (spiral point): typical for impulsión of the shaving in threaded of órificios pasantes in general preferably >1xD.

Coins of cutting: is the element that llevar the properly said action of cutting and is configured by 3 typical angles:

- α = angle of incidence, destalonado or rid (relief angle)

- β = angle of cutting or desprendimiento (rake angle)

- γ = angle of the edge or coins (edge angle) consequence of the others 2

Although the 3 angles are important the one of incidence results especially critical. In reality the males have 2 angles of incidence:

- Angle of incidence in the flanks of the teeth or profiles of thread. It is a key parameter for the provision of the males of roscar. His dimension is necessary and strategically reduced —inferior to 1º— owing to his special impact on the behaviour of the males, even to levels sub-degree (decimal of degree), by what his design results especially critical. From the design, the extreme exigencia required– to level milesimal of mm– for a precise control in the execution and in the measurement of this parameter, comports a special technical complexity.

- Angle of incidence in the crests of the teeth of the cone of entrance. It represents the 2º level of criticidad for the provision of the male. To orientative title his dimension saves a proporcionalidad approximate of 10x with regard to the previous. The exigencias required for his tutorización —to level hundredth of mm— present also a remarkable technical complexity.

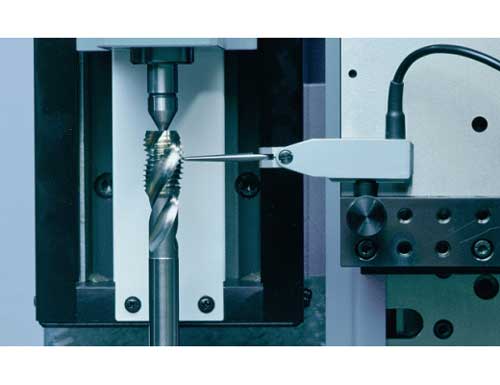

The guarantee of a suitable tutorización of the quoted parameters demands half and technological resources highly qualified. An exponent of the means is the specific team of leading technology German recently purchased by Neco-Tivoly, which provides total guarantees of measurement and constitutes an answer to the permanent challenge of innovation/improves of our male of roscar.

Exists a 3º angle of incidence, that affects to the crests of the threads, but given his drop criticidad omit references to the same.

Nevertheless in the male multimaterial the design answers to particular criteria based in experimental results to guarantee his polivalencia.

Conicidad reverse: consists in a progressive reduction of the diametral height in flanks and bottoms of thread. Oriented in steering tip–mango, his object is to reduce / minimise the high component of friction or rozamiento congenital in the work of the male by what treats of a highly critical element. His magnitude is obligatoriamente reduced (> 0,5%) and the imperative and exigencias of quality in his design and execution reach similar levels to the quoted for coins it of cutting.

Cono of entrance: zone or area of the tip with profiles truncated in cone. It realises the properly said work of mechanised or manufacturing of the thread. The function of the profiles of subsequent thread limits exclusively to an action of guided or accompaniment.

In addition to the destalonado or incidence the another characteristic parameter is the length, usually expressesed in Number of threads or teeth of thread. The combination between number of cuttings or groove (Z) and Number of threads (N), determines the thickness of the shaving cut (And), of agreement to the formula And = H/(NxZ) where H is the height of the profile of thread in mm (to orientative title H = 0,5xP).

To practical effects exist 2 typical variants of length:

- 2,5 threads or steps (type C or short) typical of males for blind orifices (helicoidal males and recta)

- 4,5 threads or steps (type B or average) typical of male go, go pasantes (male Form B or Gun)

The limitation in the length of the cone in the males for blind orifices obeys to the exigencia usual in the blind orifices, of minimisation of the zone of incomplete threads —no useful— been due to the geometry of the cone.

This detail explains the unavoidable difference in performance in favour of the male form B or pasante, whose length of cone is netamente greater (+ 80% roughly with regard to the type for blind orifices).

In accordance with all the quoted, the importance of the cone results obvious and therefore the exigencias of quality situate in maximum levels.

Finished superficial with vaporisation steam homo (Urdin)

treats of a superficial treatment by thermal sensors road, that generates a layer of ferric oxide Faith3Or4 with thickness submicra and whose visual shot sign is his characteristic black colour-bluish.

Realises in ovens of atmospheric camera specifically ready and the process —that results totally innocuous from the sanitary ware and ecological punto— consists basically in a cycle of thermal sensors treatment structured in stages with distinct escalados in the binomial time-temperature and with contribution of steam of water in a determinate phase of the same. Inside the generic frame, the data of concrete detail remain to criterion of each manufacturer what allows to obtain properties relatively different. Obviously the temperature can not surpass, in no case, the threshold of revenido (550º).

Apart from the consabido cosmetic effect, contributes a remarkable technical contribution in profit of the tool:

- The thermal sensors factor contributes a reduction/elimination the stress residual from the process of manufacture result impossible in the) what contributes to increase the life of the tool (amolados totally exentos of stress are impossible in the practice).

- The same factor contributes a fine-tuned of the edges of cut by weakening (action of burned) of the micro-rebabas associated to the micro-plastic deformation of rectified to grind what contributes to increase the life and the superficial quality of the threads (amolados totally exentos of plastic deformation are impossible in the practice).

- The oxidation contributes a micro-craterización of the surface and like consequence in the generation of crowd of translates in micro-tanks of fluent lubricante, what contributes to reduce/ delete the deterioration by adhesion (edges of cut recrecidos by welding in cold of the material worked problematic frequent in ferric materials sobe everything of low alloy).

Conclusions on the male multimetal

- The fundamental reason this family of Males is the polivalencia in terms of efficient answer to the threaded of different materials, surpassing the traditional technical barriers that imposed models with cute specialisation-material and the derivative consequences of the fact.

- Is the result of a development, based in a deep study and analysis of the problematic real in threaded with male, through a long and extensive experience like manufacturer. The development complete with the application of the ‘know how' corresponding for the wide and complex series of rediseños innovativos necessary in product and process.

- The guarantees of efficiency are endorsed by crowd of experimental results so much in the internal field (tests of threaded in our laboratory of essays R&D) as in the external field on foot of work.

- Without obstacle of his contrasted efficiency todoterreno like main aim, the males present capacities especially stood out in steels of mechanical and stainless construction.