Virtual laboratory for the fast development of products of carbide of tungsten

Particularly, when it designs a new product, in which of course it has to take into account until which point the material will be low mechanical effort, thermal sensors and chemist, to end to be able to be chosen the carbide of optimum tungsten and the processes of production adapted and with the end to comprise better the complex individual factors and his effects, is necessary to calculate all the variables that apply with the method of the finite elements (FEM).

Thus, previously to the production of prototypes of carbide of tungsten for pieces of wear and the sector of tools of cut, is especially adapted to realise a detailed analysis, simulating the processes of production and the efforts of the products. Later, the comparisons with the practical experiments show if the effects of the results calculated previously coincide with what sucede in the proofs. The virtual laboratories like the ones of

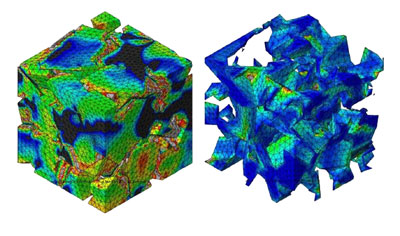

Structure of material combined óptimamente

Does evident cuán important is the simulation, already in the first phase of the development. This allows to take out conclusions about the chemical and physical reactions of the quality. “We analyse of which way the material is under tension after the sinterizado”, explains Michael Magin, responsible of development of pieces of wear of Ceratizit. Whereas the MD finds under tension, the agglutinative expands plásticamente. Of this way, already remains clear which combination of material is adapted to avoid splits in the piece sinterizada.

Density of compressesion homogénea after the simulation of processes

The processes in the chain of production pulvimetalúrgica are miscellaneous and complexes. A number of different procedures of simulation provide clarity to the definition of the parameters of the process during the pressesing and the sinterizado

If a component contracts or deforms irregularly after the sinterizado, the reason is the density no homogénea of compressesion. To avoid this, all the processes during the procedure of the pressesing owe to llevar of optimum way: the tools of pressesing owe to be designed properly and the presses has to work with the strength of necessary pressesing. In Ceratizit test these parameters in the simulation of the processes and later define them. Of this way so much the regular distribution of the density and the contraction homogénea of the sinterizado, are guaranteeed.

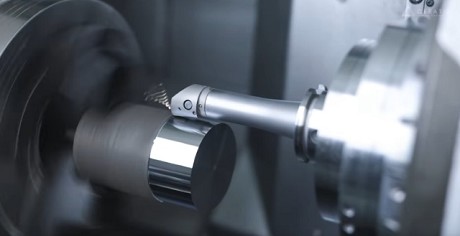

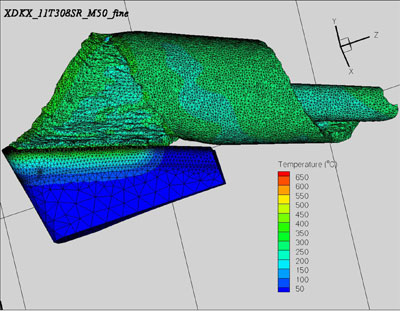

The stability of the edge of cutting and the control of shaving during the mechanised

In addition to the processes of production, can calculate the processes of mechanised of form much more realistic. Before manufacturing the prototype of a plaquita, specialists in the development of product simulate the complete process of mechanised, checking the design regarding the stability and mechanical effort of the edge of cutting. “Besides we analyse as it forms the shaving in the distinct materials to mechanise”, explains Uwe Schleinkofer, director of I + D of the division

Tools of Cut in Ceratizit. “This is decisive for the capacity of performance of the tool in practical applications. The temperature and the tension in the edge of cutting in particular, provide information on the resultant wear and therefore on the life of the tool expected”.

During the process of milling of titanium, the developing specialists analysed how produced the microfisuras in the edge of cutting. The results of the simulation integrated in the system of tools with rompevirutas F40, in the design of the edges of cutting and in the new quality of tool of cut CTC5240 that represents a world-wide innovation. Like this it is as we can offer to the customers one of the systems of greater available performance in the market for the milling of titaniums.

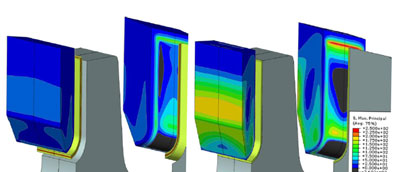

The 3 layers of the alloy of the welding of copper reduce the break by transversal effort in the teeth of the saws

If the carbide of tungsten combines with another material, like the steel, the tension that produces then is high. This is because of the mechanical properties of the materials, such as the thermal sensors expansion. The called tension of adherencia can drive to a grave failure during the mechanised. During the simulation of the union of all the process can see that the form of the sewing of the welding influences strongly in the process of soldier. When the sewing of welding is too big, restricts the flow regulate of the alloy of welding, whereas a sewing of welding too small can damage the piece of MD. When soldering the teeth of the saws, can see that using a fundente of a layer puts to the carbide under an extreme tension, causing him that rasgue when it subjects him to an excessive transversal strength. The simulations show that the use of an alloy of welding of three layers drives to a considerably inferior tension and the limits of the application of the components expand .

In addition to the simulation, in Ceratizit llevar practical experiments. And the results of these proofs reveal (for example in the teeth of the saw) that the patterns of agrietamiento distinguished coincided with precision with the breaks calculated. Like this they expose it the directors of R&D, Magin and Schleinkofer: “The current systems are able to simulate all the processes of reliable form and with realistic results. The simulation contributes of decisive way to a fast and precise development of the solutions of the hard metal”.