Key factors in the procurement of tool of cut in the SME of mechanised European of the 21st century

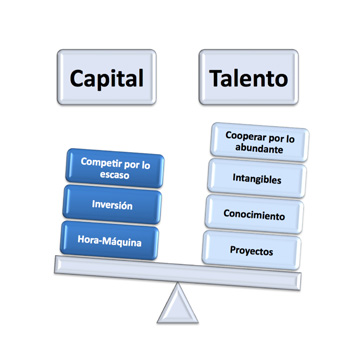

The main differences that dictates the new surroundings in which the SME of mechanised European develops his business are the following:

<#comment>|

Before 2008 |

After 2012 |

|

Competition by the scarce |

Cooperation by the abundant |

|

The investment is more important that the knowledge |

The knowledge is more important that the investment |

|

The customer hires hour-machine |

The customer hires commitments pactados in a project |

|

The capital is synonymous of success |

The talent is more important that the capital |

The new surroundings will reward to the employers that prefer to cooperate by the abundant to compete by the scarce. This means in essence that leaves to have felt to look for the investment in the machine that ‘does not have anybody' and however is much more effective to look for markets where exists guarantee of abundant business and head to they cooperating with complementary companies and on line with the own strategy.

The knowledge is more important that the investment because the important now is that the SME of mechanised focus to the global market, look for profitable projects, identify new components that manufacture and cultivate the loyalty to customers that guarantee him business at the same time that they open him new possibilities. To do all this, is very important to know use the knowledge and the capacity of analysis to take decisions on the investment that guarantee the success, perhaps much more skilled and technologically much more advanced because the priorización of the knowledge goes it to allow.

The customer no longer will hire hour-machine, this form to work in Europe has left to be profitable, in the new time the customers hire to the SME of mechanised so that it fulfil his commitments pactados by means of a project. The project includes the continuous improvement thinking in the interests of the customer, that is to say, improvement of quality, reduction of costs, innovations in the processes of manufacture and all what ensure to the customer that his component is in good hands.

Finally, results obvious that to do all the previous the talent is much more important that the capital. Talent that make possible that the SME of mechanised was hiperflexible to adapt quickly to the changes, innovative to look for permanently project of value added, intelligent to handle the knowledge in the taking of decisions, observer of the market to adapt his strategy and in permanent contact with his customer to manage his company with guarantee of success.

1. The new times require new models of procurement

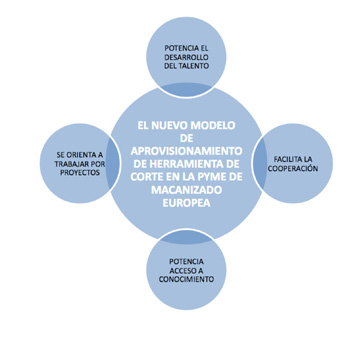

In the new surroundings to the that has to adapt the SME of mechanised European, how has to be the model of procurement of tool of cutting?

Taking the four characteristics of the new surroundings exposed previously sees easily how has to be the new model of procurement of tools of cut in the SME of mechanised.

1) Has to facilitate the tendency to the cooperation.

For this have identified three indispensable points:

- High degree of standardisation of the tools.

- Access to a wide range of tools in a same provider.

- Provider multinational.

Work with standard tools, with a provider that concentrates a wide range of tools of cutting and besides that have global presence, will facilitate the comparative of productivity or even the mobility of works of some productive surroundings to another, so much in the near surroundings as between SMEs of mechanised of other countries, and these characteristics increase the flexibility and therefore facilitate possible processes of cooperation.

2) Has to improve the access and the permanent update of knowledge.

In this sense exist two important points:

- Guarantee of an excellent technical support.

- Permanent renewal of information on new tools and new forms of use.

The provider of tool has to guarantee an excellent technical support giving continuous learning to his commercial network and hiring people that have high knowledges of mechanised and experience in workshop. Besides it has to guarantee that the knowledge that arrives to the workshop of mechanised renews permanently. Therefore it is important to work with a provider specialist and that incorporates a process of gestión of the technical knowledge that does to arrive to his customers.

3) Has to facilitate to the SME of mechanised the adaptation to work by projects.

The two more important points for this are:

- Possibility to work without warehouse of tool to minimise the cost of change of work.

- System hiperflexible of procurement that allow the change or the return of tools without bureaucracies.

When a SME of mechanised raisin to see to his customers like contractors of his machines to see them like companies for which realises different projects where the mechanised of pieces is one of the factors of the chain of value, but no the only, the procurement of tool of cut for the projects has to be hiperflexible to avoid unnecessary costs.

4) The provider of tools has to contribute an attitude that improve the talent in the SME of mechanised.

In this section appear the intangible associated to the culture of the provider of tool and to the attitudes of the people that do us arrive this culture, have identified the following points like indispensable:

- dynamic Attitude, open and collaborator of the provider.

- Innovative attitude of the provider regarding new models of gestión.

- Respect by the time devoted to the visit; attitude of efficiency and approach.

- Contributes to keep in touch to the SME of mechanised with other SMEs of mechanised to improve the attitude collaborator.

The talent is a combination of aptitudes and attitudes, therefore the provider that possess a culture with positive attitudes and enriquecedoras will improve the development of positive attitudes and therefore the talent of the SME of mechanised.

In the previous analysis appreciates like the model of procurement adopted is more important of what can resemble simple sight to adapt to the new times.

Inside this new model of procurement is very important the suitable selection of the provider of tool of cutting. And of course an intelligent gestión in this sense is very far to select the provider by vicinity, friendship or because it has to ‘give to eat to all', sentence that have listened with frequency to expresses the tendency to work with all the providers that visit the SME of mechanised and that denotes a fault of criterion in the selection of provider of tool of cutting. These emotional and obsolete factors of selection of the provider of tool of cut limit the competitiveness of the SME of mechanised much more of what some think.

2. Factors that limit the competitiveness in the process of procurement of tool of cut in the new paradigm of the SME of mechanised European

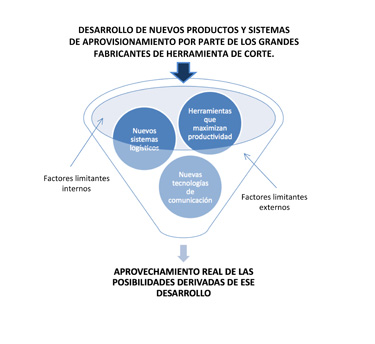

The big manufacturers of tools of cut in the world, do not leave to develop tools increasingly productive and adapted to the needs to the SMEs of mechanised. Also they project innovative solutions regarding systems of logistics that improve day in day out the rapidity with which the SME of mechanised has of the tool of cut, even some systems like the cabinets dispensers guarantee the immediate availability. Without forgetting the wide field of open development with the use of the new technologies to realise on-line requests, follow-up of these requests, visibility of the availability, access to data of cut, geometrical factors of the tool, etc.

Said developments are thought for maximizar the quality of the product and service, but because of a series of internal and external factors to the SME of mechanised the aprovechamiento of the maximum provision of the tools or the available services no always is possible, what conditions us in the selection of these and carries us to lose competitiveness with regard to which better take advantage of these resources.

To continuation identify and analyse said factors limitantes of competitiveness in the process of procurement.

2.1. Identification

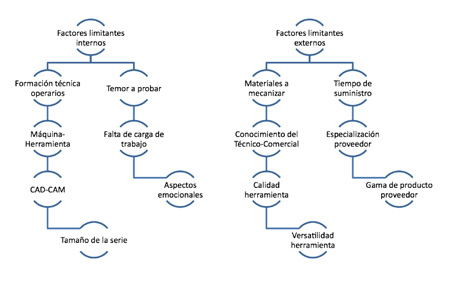

In the present work have identified 14 factors that limit the competitiveness of the SME of mechanised European in the process of procurement of tool of cutting. Seven of them are of internal character and seven of them of external character.

The factors of internal character a priori are the easiest to control because by definition they depend on the own company, nevertheless, surprisingly observes a high difficulty to handle these factors by part of the directors of the SME of mechanised. Perhaps it was because of the scarce importance that attributes him to the tool on his influence in the competitiveness. The seven internal factors are:

1. Technical learning of the operario.

2. The machine- tool.

3. Programs of CAD-CAM and direct programming or manual in machine.

4. Size of the series (series of pieces, long or short).

5. Fear or fault of time to test tools more competitive.

6. Fault of load of work.

7. Emotional appearances that limit the freedom of selection of provider.

The factors of external character result surprisingly the easiest to control, since the majority of them control with the selection of a suitable provider. Claro that for this have to handle properly the emotional appearances of limit the freedom of selection of provider, that is the seventh internal factor identified. The seven external factors are:

8. The materials to mechanise.

9. Knowledge of the commercial technician.

10. Productivity and quality of the tool.

11. Versatilidad Of the tool.

12. Time of supply of the tool.

13. Degree of specialisation of the provider.

14. Range of tools that the provider of tools is able to supply.

2.2.- Analysis

2.2.1.- Internal factors

1. The degree of technical manufacturing of the operario will be the one who limit the aprovechamiento of all the other existent resources by what is very important personnel very formed in the knowledge of the machine, of the tools of cut, of the tooling of subjection, of the programs, of the materials, of the metrology, etc.

2. The machine-tool influences of decisive way in the election of the tool of cutting. At present it is still frequent to find workshops that for example are realising all type of operations in stainless steels or in resistant alloys to the heat and whose machines do not possess internal refrigeration, by what the election of the tools sees reduced to which better work in these conditions and no to the most productive and ideal. Similar situations can find with regard to the number of revolutions of the husillo, power, speed of advance, number of axles of work, etc. All these characteristic are conditionings to the hour to choose the suitable tool and in many of the cases, limitantes of the own capacities of the tools.

3. The use of programs of CAD-CAM and his capacity of handle, also is an influential factor in the election of the tool of cut, workshops that have of them and handle them fluently, do not show “pereza” to the hour of reprogramar a tool that contribute him greater productivity. In these workshops also have observed big advantages when using standard tools to realise works that others require of special tools; usually more expensive, with time longer of acquisition and with a productivity and hygiene of lower process that the standard tools. A good handle of these programs also allows that of form relatively simple, do simulations with new tools, purportedly more productive and with his parameters, seeing of fast form if these contribute an improvement in the productivity and freeing us of the links to which attach us some tools, that by the mere fact that the program realised thinking in them, even having a lower productivity, keep on being those that realise the work.

4. The size of the series also conditions the election of the tool, in series of short pieces or very short, look for tools more economic (sometimes choose HSS in place of HM), or look for tools very universal so that we can use them of recurrent form in a wide fan of operations. In these cases do very useful the tools of plaquitas interchangeable; simply changing the quality of the plaquita, can use it in materials entirely distinct. When it treats of long series, requires that the tool was the most productive and of the best possible quality, to reduce to the maximum the times of production together with a high hygiene in the process.

5. The fear or fault of time to test tools more productive, in a lot of occasions carries to not to pose us new tools that can improve our processes. In this case it is very important the confidence in a commercial technician very formed, that analyse of fast and simple form, the process of mechanised and advise on possible improvements.

6. The fault of load of work carries us many times to select tools more economic and less productive, what think that it carries us to be less competitive. From our punto, all the time that are able to save in the mechanised thanks to the use of a tool of high productivity is time that can employ in thinking how improve all our processes so that we go in in a very positive circle of permanent improvement.

7. The emotional appearances that limit the selection of provider separate to the SME of mechanised of the objective analysis of his interests like company and in occasions suppose a ballast for the continuous improvement of the system of procurement. The best is to have criteria of selection and continuous evaluation of the providers settled in concrete aims. Of this form although the emotions keep on being important in the relation with the providers, these will not be a factor limitante.

2.2.2.- External factors

8. The distinct materials to work condition the election of the tool of cut, but in this case can not us pronounce on a positive or negative influence.

9. The commercial technician perhaps was the external factor that more strongly can influence in the selection of the most suitable tool. A good knowledge of the tools that recommends and a good technical advice (data of cut, recommendations of use, possible strategies, etc.), can be a fundamental help for the personnel of the workshop. To be able to llevar successfully his work, the technician will require a good technical learning and a constant learning. The empathy also is fundamental in the daily work of the commercial technician, the know which are the real needs of each workshop and know offer the tools that better adapt to these, the realisation of proofs of new tools when honestly it think that really it can offer an improvement in the process.

10. The productivity and the quality of the tool influence directly in the competitiveness of the workshop, a tool of high performance and therefore productive and of quality will help us to reduce the times of mechanised with total hygiene of processes and with a life of considerable tool. The selection of tools nowadays are directed almost always to the “mechanised of high performance” or HPC by his acronyms in English, or to the “mechanised high speed” or HSC.

11. The versatilidad of the tool. The selection of versatile and universal tools like alternative to special tools, can do us win competitiveness. This type of tools have gone livestock in productivity, due to the fact that they are products that have had time of evolution and has realised them modifications and have gone incorporating improvements that do them more reliable and of greater performance.

12. The times of supply of the tool. In the situation of current crisis and that come suffering from the 2008, the can resupply us of fast and safe form of the tools of cut, allows us the reduction of investments in stock of tools in the workshop and the can do use of this money for other needs, what also contributes us a plus of competitiveness.

13. Degree of specialisation of the provider, the influence that has the resupply us of tools of the hand of a highly specialised provider is of double sense, from the side of the provider will report all the knowledge on the product sold to the customer and from the side of the mecanizador will generate a feedback that will go directly to the manufacturer, that will do definitely that the product improve.

14. Range of able tools to supply. The possibility to be able to resupply us in a very high percentage of all the needs of tool of a workshop, in addition to comfort, will do us save in time of research of tools.

3. Conclusions

After the economic crisis initiated 2008 the surroundings of the SME of the mechanised European has gone through an important process of change and has given place to some new economic surroundings with new rules of game. In this new surroundings the cooperation between companies is and will be key to contribute greater flexibility to the businesses, the customers hire companies that develop projects in place of hour-machine, and the knowledge and the talent take strength in front of the capital and the investment. The new times also sue new models of procurement in which the providers of tool of cut have to be analysed under new criteria.

In the article also analyse the factors that limit the aprovechamiento of the available developments in the market of tool of cutting. Developments in which the big groups multinationals manufacturers of tool of cut invest a lot of resources, but that arrive of partial form to the SME of mechanised because of internal and external factors. We aspire to that the analysis of these factors contribute to his control and therefore to a decrease of his negative effect on the competitiveness of the SME of mechanised.